|

|||

|

|

|||

|

Page Title:

Stack Spacing and Roofing Protection. |

|

||

| ||||||||||

|

|

TM 38-400/NAVSUP PUB 572/AFMAN 23-210 MCO 4450.14/DLAM 4145.12

storage decreases, thus permitting easy readjustment or

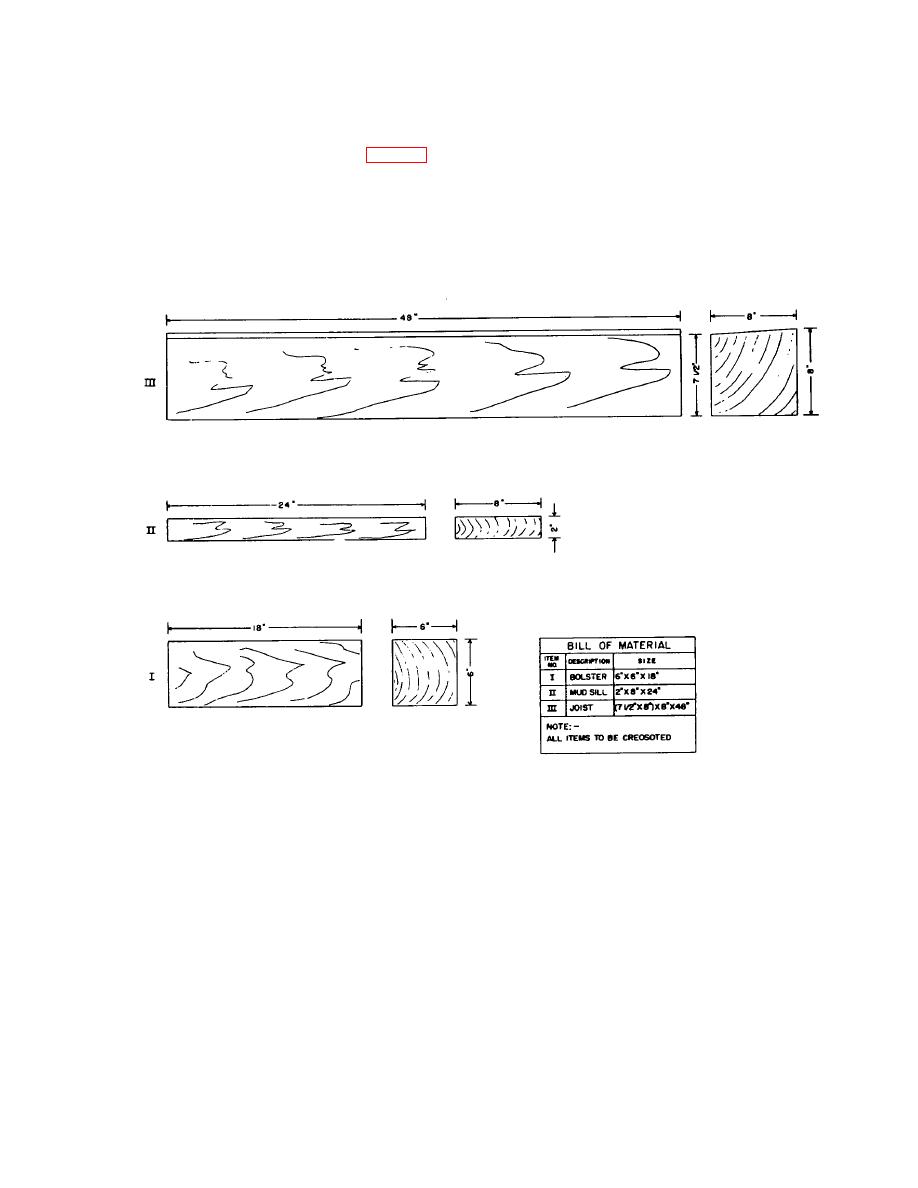

e. Component parts of the portable foundation.

layout of the lumber storage area. To facilitate storage

The portable foundation consists of three component

operations, foundation components should be unitized in

parts-6-by 6-by 18-inch blocking (71/2 by 8 in) by 8by

the quantity required to store an average car load of

48-inch joists, and 2-by 8-by 24-inch mud sills (fig 5-12).

lumber and placed at strategic locations throughout the

Utilization of these mud sills produces a bearing surface

lumber storage area. Foundations not required for

of approximately 11 square feet for each unit stack,

immediate use, except those strategically located about

which is sufficient to support maximum unit load stacks

the yard, should be stored in one central location by

on yard surfaces that will withstand the normal

component type.

operations of heavily loaded fork trucks.

These

foundations are removed easily and unitized as lumber

Figure 5-12. Diagram of lumber foundation components.

need, however, for building flues into drafts 4 feet or

5-7. Stack Spacing and Roofing Protection.

less in width has not been demonstrated. The sum of

the width of flues in hand-stacked piles equals about 20

a. Horizontal spacing.

percent of the width of the stack. Flues within the drafts

(1) General. Although stack spacing will vary

should not be required if 6 to 12 inches are allowed

with different situations, stacks of stickered or solid piled

between the sides of the stacks of unitized lumber in the

drafts of lumber should not be placed too close together.

yard. With this arrangement, movement of air in the

Circulation around the stack is necessary if drying is to

spaces adjacent to the stacks will induce horizontal

take place in lumber, which is above an air-dry

movement of air through the draft and accomplish

condition, and to prevent dry lumber from picking up

drying. When drafts are stacked in this manner, the

moisture from stagnant, humid air pockets.

spacing between the stacks takes the place of flues built

(2) Spacing between stacks of unitized

into hand-stacked piles; therefore, this space should

lumber. Lateral spacing between stacks should be 6 to

equal approximately 20 percent of the unit stack width.

12 inches. Vertical passages or flues are somewhat

more difficult to build into drafts of lumber than in the

relatively wider hand-stacked piles. The

5-13

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |