|

|||

|

|

|||

|

Page Title:

Load handling maneuvers for trainees. |

|

||

| ||||||||||

|

|

TM 38-400/NAVSUP PUB 572/AFMAN 23-210 MCO 4450.14/DLAM 4145.12

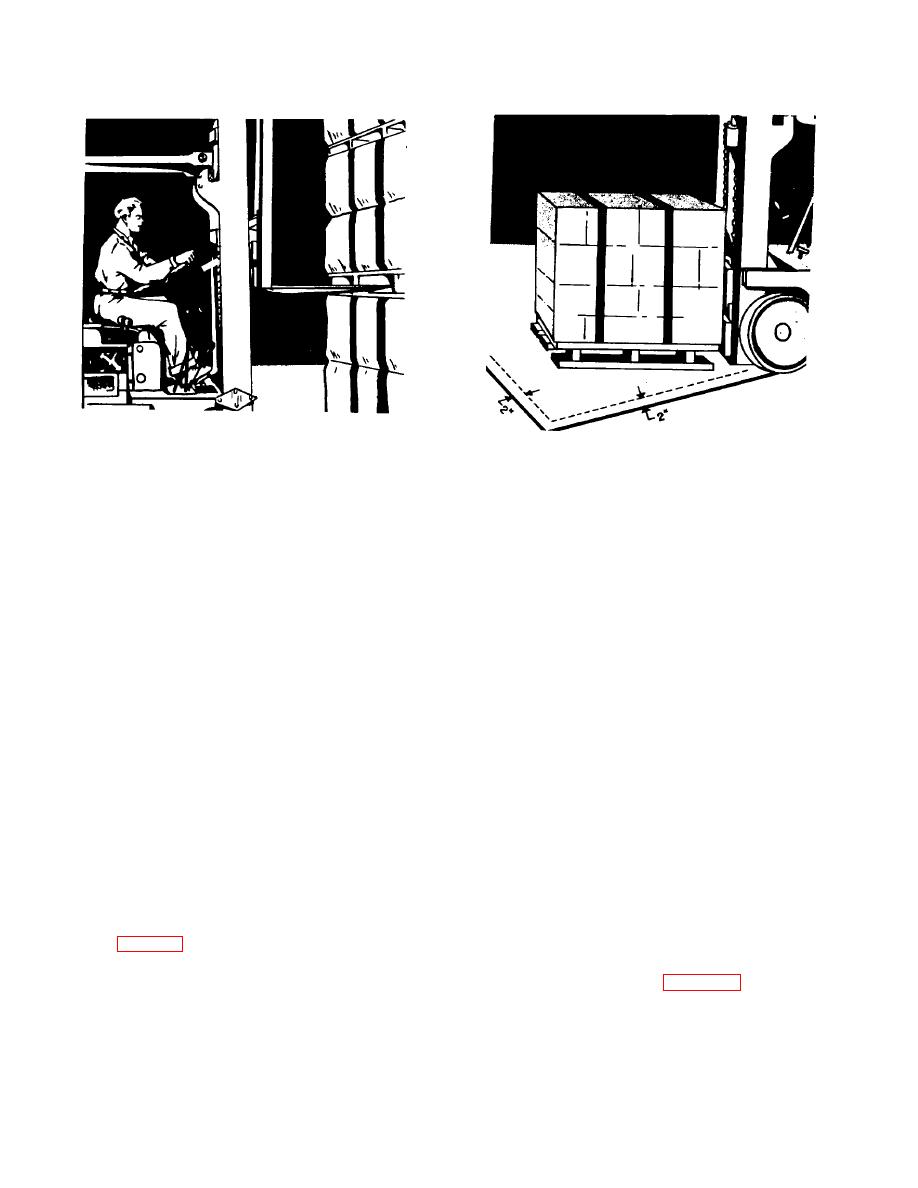

Figure 4-116. Approaching a pallet. Forks must

Figure 4-117. In one maneuver, the trainee spots a

enter at an equal distance from the center stringers.

pallet load on a right angle drawn on the floor. This

must be done with no more than 2 inches of lost

(2) Inserting forks. The forks of the truck

space.

should be inserted into the pallet as far as they will go.

It is important that the operator have the load as close to

One swing is all the maneuvering that is permitted to

the heel of the fork as possible.

place the load. The instructor should demonstrate each

(3) Lifting and moving the pallet. The trainee

operation before turning the fork truck over to the

should be instructed how to apply the lift control to lift

trainee. Upon completion of a maneuver by the trainee,

the pallet from the floor, apply the tilt control to tilt the

the instructor should point out those actions that were

mast back, and then apply the travel controls to move

performed correctly and make appropriate comments on

the machine forward or backward.

those that were not. In the problem of spotting a pallet

(4) Lowering the pallet. The trainee should

load at a right angle in one maneuver, the instructor will

be shown how to lower the pallet to the floor and then tilt

point out that extra backing and shifting causes the

the mast to a vertical position so that the forks can be

greatest loss of time in a fork truck operation. If

removed easily.

operators are trained to spot a load on the first

(5) Using the mast tilt. Demonstrate how the

approach, this time loser will be eliminated. The one-

tilt is used to achieve the following:

swing maneuver is accomplished by having the eye

follow the path of the drive wheel on the inside of the

(a) Lean the load against the back rest

turn. As the center of pivot of the machine lies on the

for stability during movement.

line formed by the drive axle, it is obvious that the drive

(b) Position loaded pallets during

wheels are the key to the actual spotting of the load.

stacking.

After several attempts, each trainee should be able to

b. Load handling maneuvers for trainees.

spot a load on the right angle with no more than 2

(1) Lesson one.

inches of lost space.

(a) The trainee lifts a pallet load with

(b) The next step is to spot a pallet load

the fork truck and, after making a turn around the

adjacent to another. This also must be performed in

training area, spots the load on a right angle drawn on

one swing of the machine. The fork truck approaches

the floor (fig 4-117).

the stack (pallet load on the floor) by crossing in front of

the stack rather than by approaching from the opposite

side toward that stack (fig 4-118). If the stack is

approached from the opposite side, the pallet load will

move away from the stack when the fork truck is turned

to set the

4-84

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |