|

|||

|

|

|||

|

Page Title:

Determining film bag size and thickness. |

|

||

| ||||||||||

|

|

TM 38-400/NAVSUP PUB 572/AFMAN 23-210 MCO 4450.14/DLAM 4145.12

shrink direction gives a more consistent shrink and

primary shrink here is in the vertical direction rather than

the circumferential. This type of shrink direction tends

tends to keep film from pulling away from the bottom of

the pallet. This factor is extremely important since the

to cause the film to pull away from the bottom of the

pallet. This can be controlled by guiding the heated

purpose of the application is lost if the film does not

tunnel air primarily to the bottom of the pallet.

tightly grasp the pallet. The gusseted bags are rolled,

sealed, and perforated from gusseted tubing. The

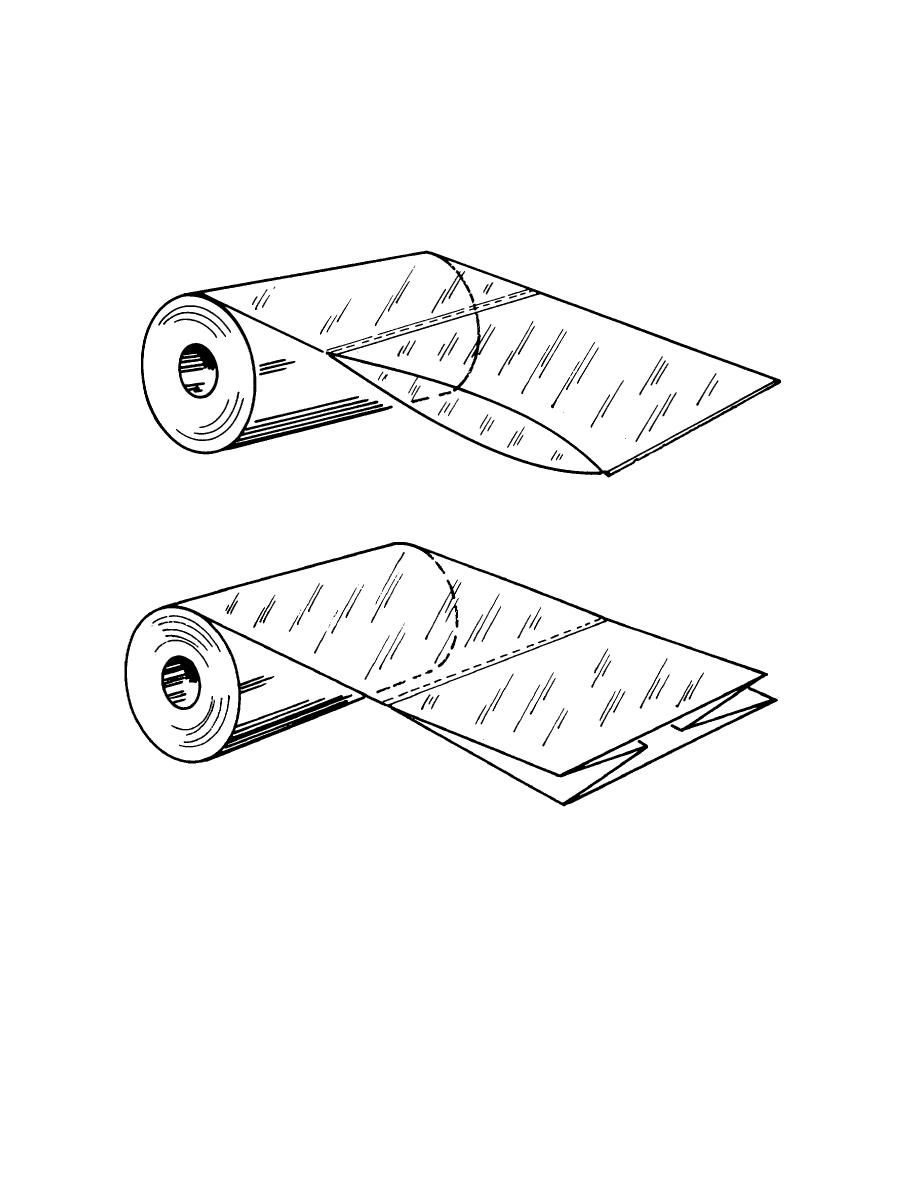

Figure 3-62. Centerfold bags.

Figure 3-63. Gusseted bags.

e. Determining film bag size and thickness. Bags

(c) Length-one half of depth of load

are specified by width, depth, length, and gauge.

plus height of load (including pallet) plus 4 inches.

(1) Bag size determination is based on the

(2) Thickness (gauge) of the film material

needed is determined by the weight of the pallet load

following:

and type of film to be used (para 5.1.2.3., MILSTD-147).

(a) Width-approximately 4 inches more

f. Advantages of shrink wrap. The advantages of

than load width.

shrink-wrap palletizing make it desirable for many load

(b) Depth-approximately 4 inches more

bonding applications.

than load width.

3-90

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |