|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 38-400/NAVSUP PUB 572/AFMAN 23-210 MCO 4450.14/DLAM 4145.12

(g) Rubber hydrochloride.

shrink-film surface area is approximately 10 percent

greater than the surface area of the palletized load.

d. Shrink-film characteristics.

Shrink tension is thus applied after this 10 percent has

(1) Because

of

its

performance

been shrunk to fit the contour and allows the film to

characteristics and low cost, polyethylene film is the

become a structural part of the package.

most widely used. The ability to stabilize heavy loads

becomes apparent when it is realized that the applied

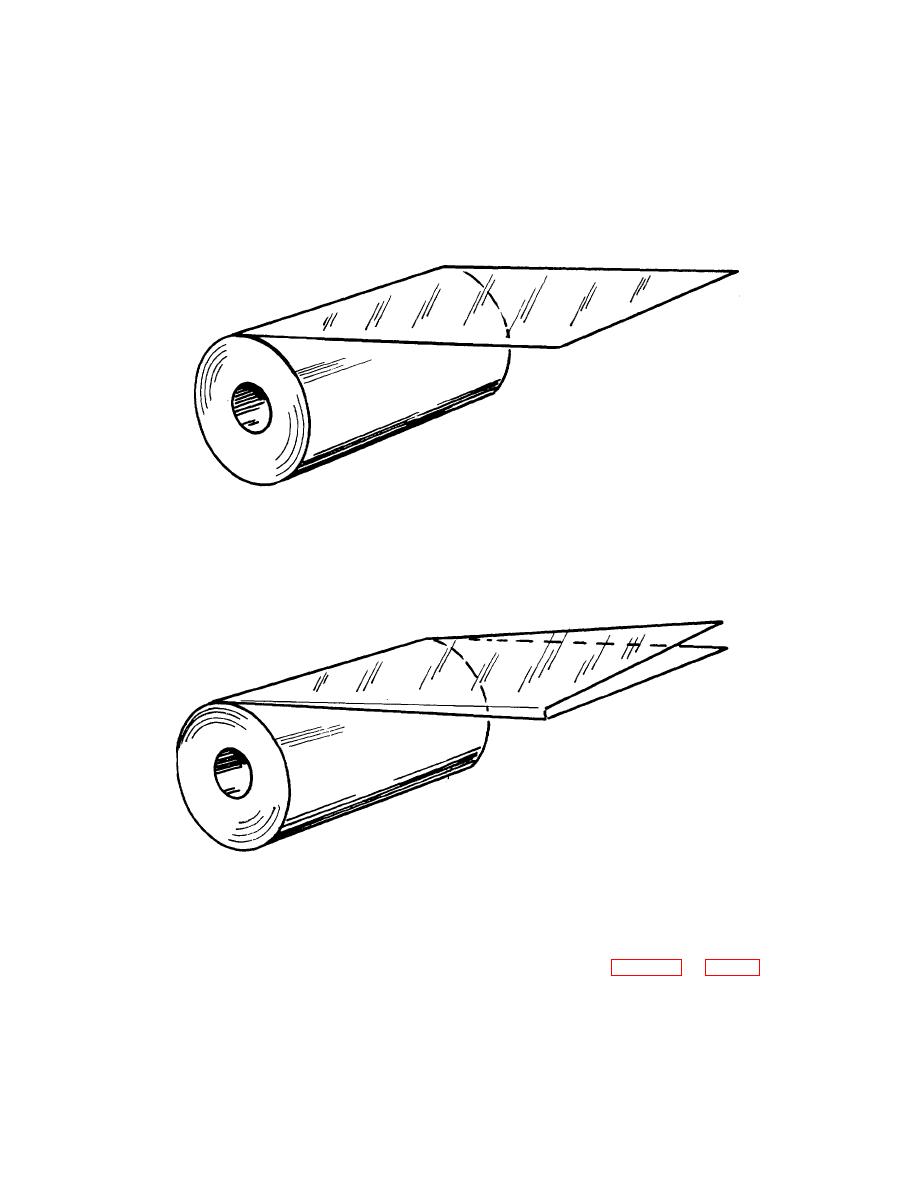

Figure 3-60. Flat sheeting.

The film shrinkage can be controlled in two directions,

(2) In film production, controlled stretching

either in the circumferential direction or height of the

builds stress characteristics into the film. Heating the

load.

film releases the built in stresses causing it to shrink.

Figure 3-61. Centerfold sheeting.

(3) Thickness of polyethylene shrink film

elasticity of film, makes it an outstanding containing

used varies, depending on the restraint requirements.

medium.

Most industrial applications use film 2.5 to 8 mils thick.

(4) Shrink-film bags can be either centerfold

The ability of film to stabilize a heavy load is easy to

or gusseted types (figs 3-62 and 3-63). The centerfold

visualize when one realizes that a restraining force of

bags are rolled, sealed, and perforated from centerfold

2,000 PSI sometimes occurs over the entire area of the

film and have their primary shrink around the

load surface. This factor, together with the inherent

circumference of the load. This type of

3-89

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |