|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 38-400/NAVSUP PUB 572/AFMAN 23-210 MCO 4450.14/DLAM 4145.12

(b) Position dunnage units to ensure

g. Operational procedures.

maximum effective contact with the part of the load they

(1) Installation.

are to brace. Top tier units of a 2-tier installation which

(a) Measure void space between cargo

must be inflated several feet above the car floor may be

surfaces where dunnage units are to be inserted.

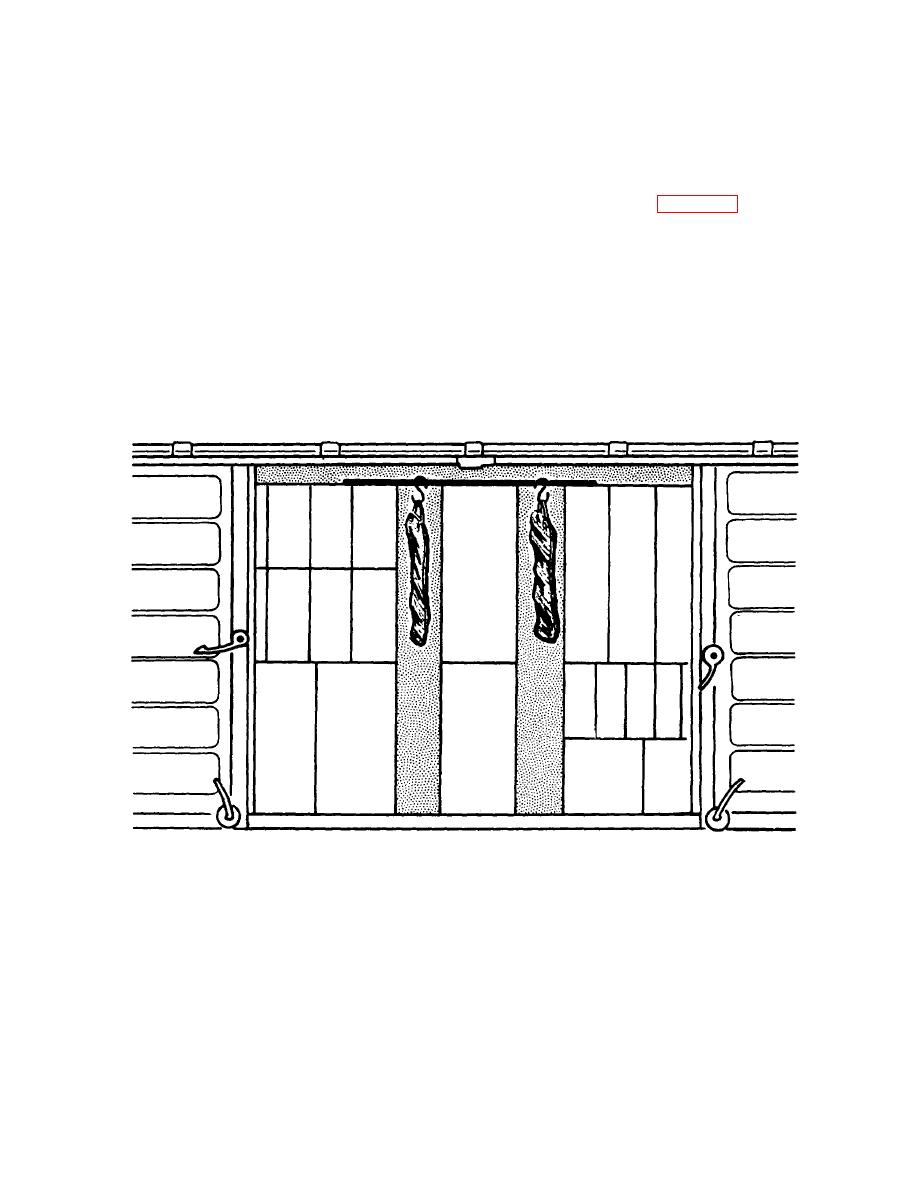

suspended in position for inflation by hangers attached

Determine the number of units required based on

to dunnage handles (fig 3-52).

This can be

horizontal and lateral void spaces, number of rows of

accomplished by spanning the void space with a bar

cargo, number of tiers of cargo, and characteristics of

across the top of the two load sections and then

cargo. Determine size of units required based on

suspending the bags with two hangers hooked through

dimensions of surfaces facing the void. Determine the

the dunnage handles. Bags are then inflated just

number of buffer boards required, if any.

enough to secure the units in position. At this point, the

suspending hangers and crossbar should be removed to

NOTE

prevent binding the hangers against the bags. Care

Loading practices which ensure tight

should be taken to assure that valves are positioned for

cargo positioning will minimize void

ease of inflation/deflation and pressure readings.

spaces between containers and

reduce cargo movements upon

dunnage inflation.

Figure 3-52. Technique for hanging dunnage units preparatory to inflation.

cushion within a 2 to 5 PSI range as restricted by load

(c) Inflate each unit to proper air

characteristics.

Pressure may be increased to a

pressure using air compressor/air supply and inflation

maximum of 8 PSI, depending on load characteristics,

kit. When more than one unit of pneumatic dunnage is

when initially compacting cargo. (Reminder: three-

placed in a conveyance, the inflation process should be

quarters PSI max in truck trailers/containers.) This over

alternated from one unit to another until all units reach

inflation must then be "bled off' to the proper shipping

desired pressures. This will assure that each unit will

pressure. When inflation is completed, tighten each

assume regularity in contour and size with subsequent

valve stem by hand (do not use a wrench or pliers to

firm positioning. Inflation requires only a few minutes

tighten valve). Properly inflated and positioned units will

per unit depending upon output volume of air

maintain correct contour in void space, but an

compressor/air supply. A high volume air supply is most

suitable.

Each unit is designed to normally

3-83

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |