|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 38-400/NAVSUP PUB 572/AFMAN 23-210 MCO 4450.14/DLAM 4145.12

slack begins to develop within the load, repeated

impacts may cause a void large enough to allow the

containers on the top layer to fall between the load and

the ends of the car. To protect against damage in rigid

braced loads, containers will be loaded tightly with the

strongest parts arranged to provide support lengthwise

of the car. All loads (excluding floating loads) should be

loaded or braced to minimize any possibility of

movement.

3-70. Floating Loads . (Not permitted for shipments of

explosives, ammunition, and other hazardous materials,

nor permitted in any boxcar equipped with under-car or

end-of-car shock mitigating cushion devices.)

a. Types of floating loads. There are two types of

floating loads: the full floating load and the controlled

floating load commonly called the "Snubbing Method."

Many items present special loading and bracing

problems because of the weight, size, shape, or fragility;

such items of this type brought about the development

of the floating load. For further information concerning

loading to withstand the various types of pressure, see

AAR pamphlets 14 and 21.

b. Controlled floating load.

(1) Description. When using the controlled

floating load, blocking is not applied against the front or

rear of the unit or the units to be shipped. Generally,

the units that are to be shipped by this method are items

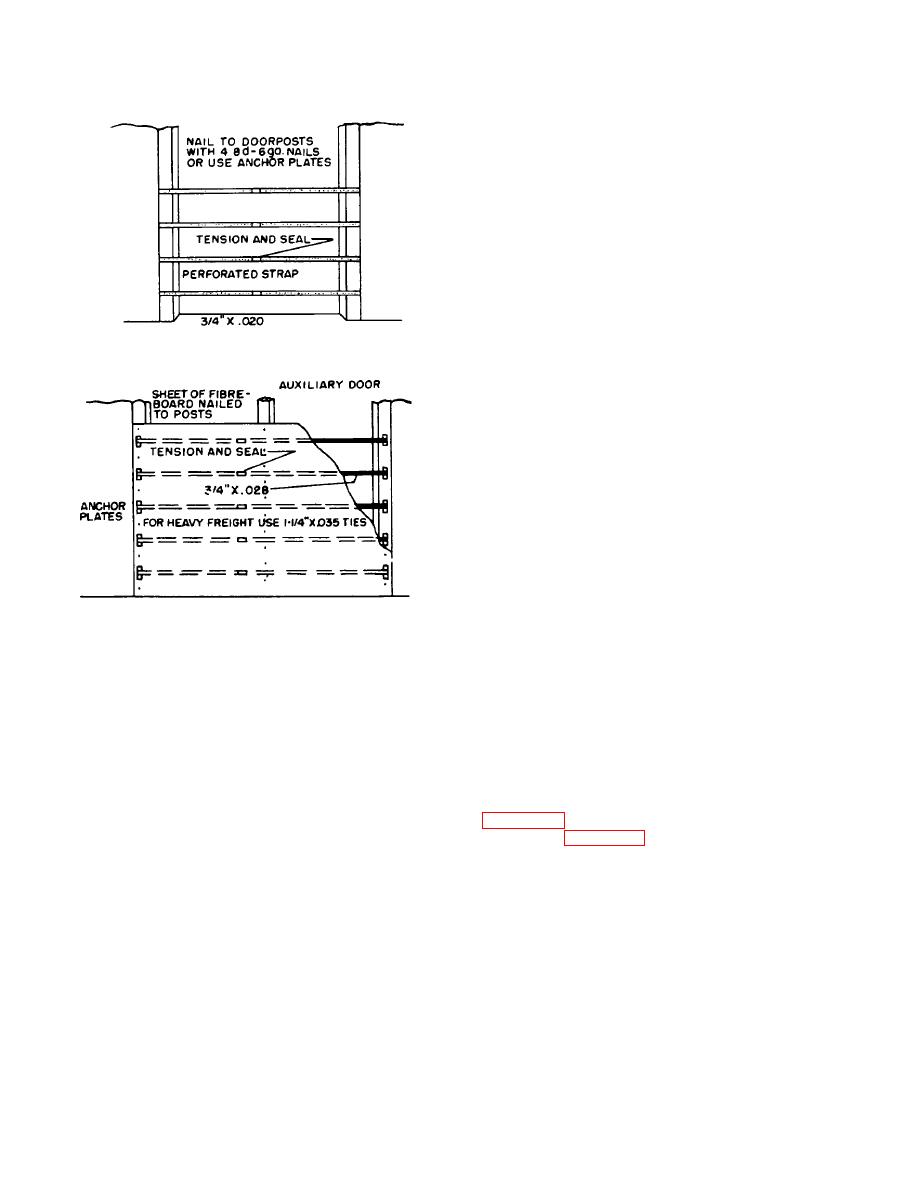

Figure 3-15. Use of steel straps for double door

that are skidded (i.e., engines, machine tools,

auto boxcar.

generators, or large motors); snubbing or braking

devices are applied against the side of the skids. Under

(4) Prevention of lateral movement.

To

lengthwise impact, the shift of the skidded item is

provide adequate protection against lateral movement

controlled and the item is held in contact with the floor of

at all times, the load must be tight crosswise. Proper

the car. Thus, the greater part of the shock forces are

blocking and bracing must be applied to prevent the

dissipated through the friction and riding of the skid

load from shifting or moving out of alignment.

structures. The item is actually isolated from lengthwise

shock forces. There are two commonly used snubbing

e. Lengthwise pressures. Most damage in rigid

devices-antiskid plates and lag screws. The antiskid

braced loads is prevented by loading containers tightly

plate and method of application are shown in A and B,

to prevent development of slack within the load. Once

shown in C, figure 3-16.

3-48

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |