|

|||

|

|

|||

|

Page Title:

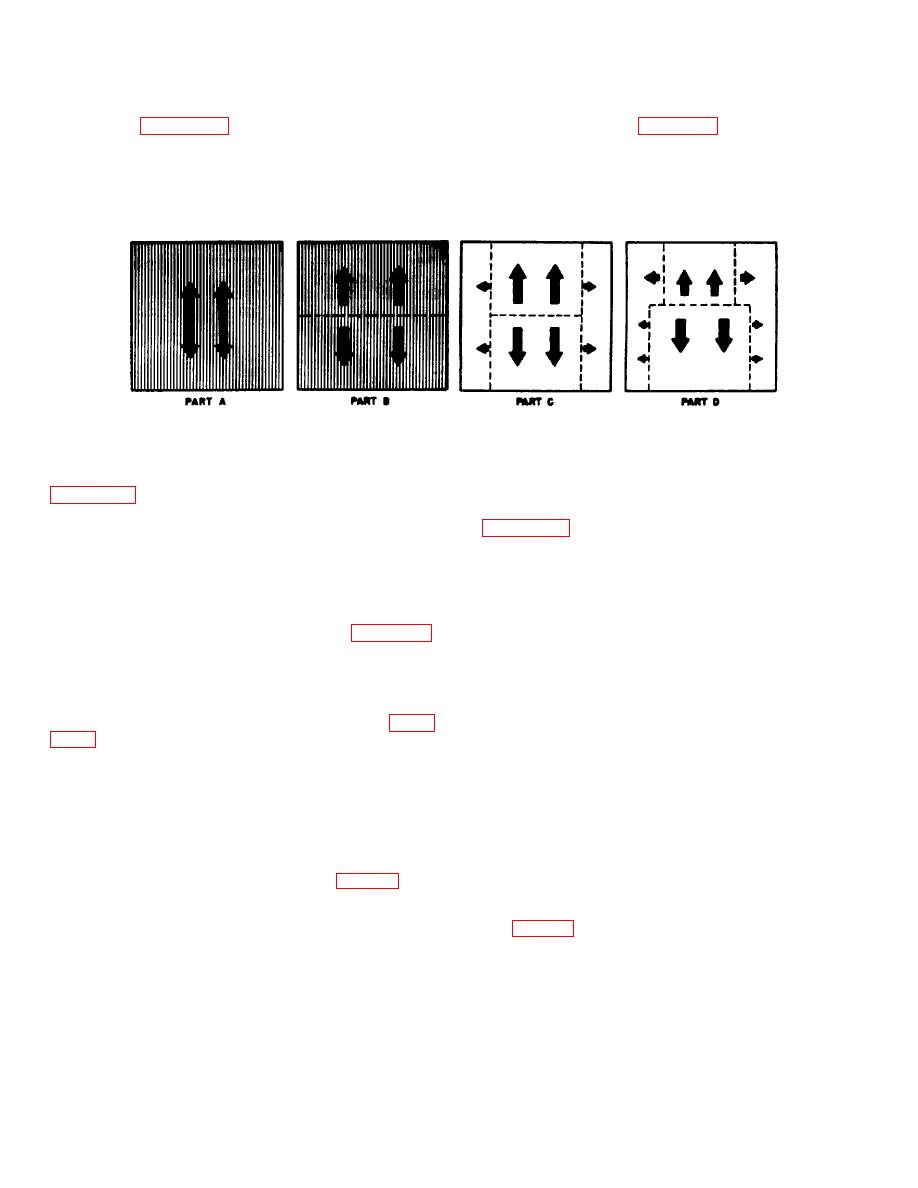

Figure 2-31. Example Direction of Storage Arrangements |

|

||

| ||||||||||

|

|

TM 38-400/NAVSUP PUB 572/AFMAN 23-210 MCO 4450.14/DLAM 4145.12

equally over all working aisles thereby relieving

(3) The simplest but most inflexible

congestion.

disposition of storage space is storage of a single item

(2) Figure 2-31 shows a layout for large lot

aisle to aisle shown by figure 2-31, part A. With 4 pallet

loads stacked in each space, there are faces for 17

storage developed in respect to direction of storage.

different items, with each row containing 68 pallets.

This was developed based on the direction of storage in

This is the equivalent of about two carloads of materials.

a bay 80 feet square. Columns and other obstructions

This layout does not provide for storage of small lot

are not shown in this arrangement.

items.

Figure 2-31. Example Direction of Storage Arrangements

held in quantities of two carloads or more. The depth of

(4) One method for increasing the number of

side-to-back bays varies from one to four pallets to

rows and reducing the depth of each row is shown by

provide a variety of short rows. Pallet racks placed

side-to-back in bays permit fuller space utilization.

imaginary line perpendicular to the direction of storage,

and in each row different items are placed in opposite

present a standard layout for any class of materials, but

directions from this line. This practice is known as

only to point out what can be done with a fixed space

"back-to-back" storage and is standard for all storage

and various aisle arrangements to provide maximum

using the forklift truck and pallet system. This method

flexibility for storage operations.

allows faces for 34 items instead of 17 and each row is

only 40 feet deep, the equivalent of 1 carload. This

b. Basin bin, shelf, and rack layout criteria. The

layout is an improvement over that shown in figure 2-31,

amount of space assigned to a specific item within a bin

part A; however, it still does not make provisions for

section is governed by the factors shown in paragraph 2-

less-than-carload quantities.

9 above. However, the size or weight of an item is not

necessarily related to its popularity.

Fast moving

(5) Another method of storage which provides

binnable items, whether large or small, must be

further flexibility is obtained by placing short rows of

reassigned space adequate to minimize replenishment

pallets along the sides of a large bay as shown in figure

frequency, time, and effort. There are many factors

2-31, part C.

Stringers for these pallets are

favoring issues from bin locations and the repetitive

perpendicular to the predominant direction of storage;

issue of small quantities of binnable-type items from

this is known as "side-to-back" storage. An

imaginary

bulk storage can rarely be justified. Proper use of bins

line is drawn and small lots are placed from this line out

will minimize the inventory and security problems found

to the aisles. Using all aisles as faces of stacks

where there are broken cases of binnable-type items in

provides space for small lots without increasing the

bulk storage locations. Fast moving items should be

number of aisles and without sacrificing accessibility.

kept in the center levels to facilitate issue and the heavy

(6) The off-center division shows how further

items should be placed in the lower levels. Lightweight

variety in row sizes can be provided (see fig 2-31, part

items should be placed on the upper levels. Bin

D). The back-to-back line is set off-center which

shelving arrangements are developed on a sheet plan

provides one very large bay and one of intermediate

(see fig 2-32).

depth. Such a layout is desirable only when there is

assurance that a substantial number of items will be

2-30

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |