|

|||

|

|

|||

|

Page Title:

Detroit Diesel Allison X1100-3B (Transmission) |

|

||

| ||||||||||

|

|

NAVAIR 17-15-50.4

TM 38-301-4

T.O. 33-1-37-4

CGTO 33-1-37-4

COMPONENT:

Detroit Diesel Allison X1100-3B (Transmission)

LUBRICANT: MIL-L-2104

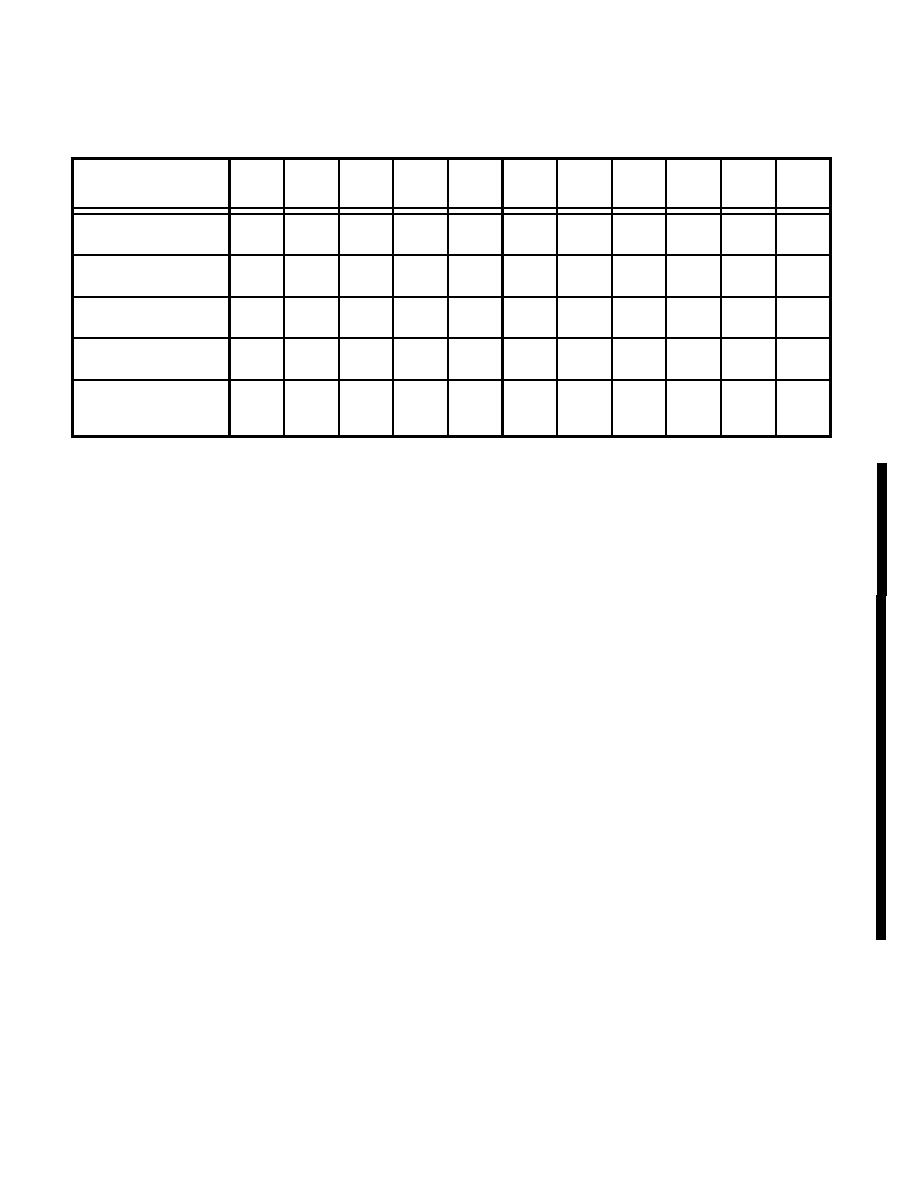

Fe

Ag

Al

Cr

Cu

Si

Sn

Ni

Pb

Mo

Mg

Normal Range

0-147

0-8

0-171

0-7

0-653

0-27

0-32

0-6

0-227

Marginal Range

228-

654-

172-

471-

28-34

33-51

7-10

8-12

9-12

High Range

325

903

300

676

Abnormal

677+

13+

301+

13+

904+

35+

52+

11+

326+

Abnormal Trend

(PPM Increase

63

6

50

3

78

6

10

3

65

in 10 hrs)

TECHNICAL INFORMATION

The brake and clutch plates in the transmission are sintered bronze. When the iron and copper in the transmission are

increasing at approximately the same rate, the plates may need adjustment, but are probably worn excessively, and the

transmission may fail. This is because the plates are worn through and the iron is coming from the backing plates.

The transmission is air-cooled; therefore, there should be no ethylene glycol contamination problems.

Probable sources of wear metals:

Fe - Steel gears

Ag - Hydrostatic cylinder cups

Al - Torque converter, oil pump, and main housing bearing

Cr and Mo - Steel alloys (usually < 4 PPM)

X1100-3B transmissions should not be removed or have the oil changed for silver (AG) wear metal test findings of 13 (PPM)

or greater unless other abnormal wear metal indications are present.

When levels of silver of 13PPM or greater are indicated, without increases in other wear metals, AOAP labs will advise the

equipment unit to conduct the following functional test in lieu of advising maintenance or servicing. The functional test is

applicable only for indications of abnormal silver findings with no increase in other wear metals.

TQCOM, M1A2/SEP PM office in coordination with Allison, Inc. (OEM) recommended maintenance personnel conduct the

following operational checks to determine transmission operational performance. Maintenance personnel should perform a

functional test of the hydrostatic steering unit (HSU) on a hard or paved surface.

1. Select pivot steer, tac idle and perform a full 360 left steer turn, then return to a no-steer position in less than 20 seconds.

2. Next, perform a full 360 right steer turn and come back to a no-steer position in less than 20 seconds.

3. If the tank pivots in both directions (left and right) in less than 20 seconds (in each direction), the HSU is performing

satisfactorily. However, if the tank fails to turn in either direction or fails to cycle within the specified time, perform this

procedure again ensuring that the brakes are not partially applied. If it fails to meet the specified functional test operational

requirements again, notify the appropriate maintenance personnel.

4. If the tank performs properly, no further action is required.

Until the current problem is resolved, report all X1100-3B transmission serial numbers with test findings where Ag 'only'

exceeds the AOAP criteria to TACOM/PM M1A2/SEP Abrams Quality Assurance through PM AOAP.

APPLICABLE END ITEMS

M1, M1E1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |