|

|||

|

|

|||

|

Page Title:

Detroit Diesel Allison 8V71T (Engine) |

|

||

| ||||||||||

|

|

NAVAIR 17-15-50.4

TM 38-301-4

T.O. 33-1-37-4

CGTO 33-1-37-4

COMPONENT:

Detroit Diesel Allison 8V71T (Engine)

LUBRICANT: MIL-L-2104

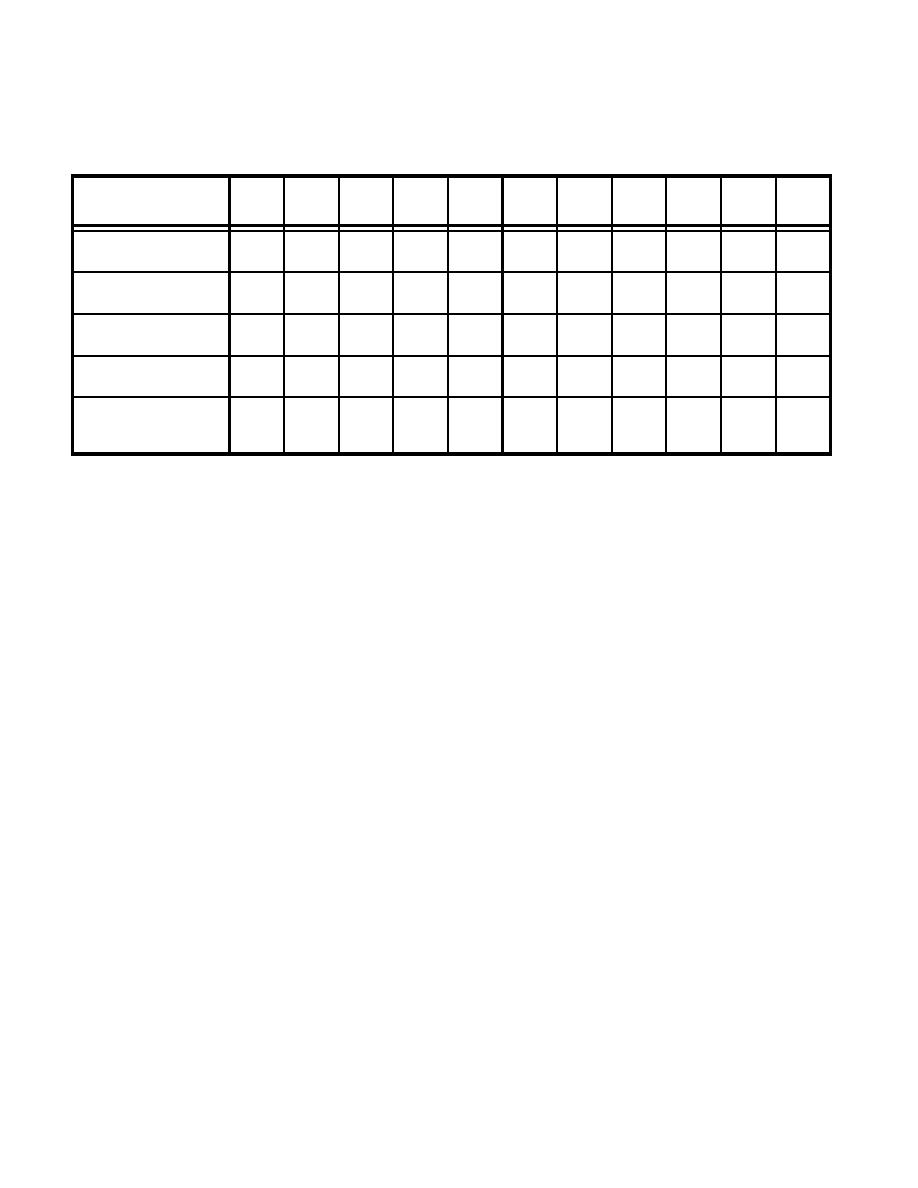

Fe

Ag

Al

Cr

Cu

Si

Sn

Ni

Pb

Mo

Mg

Normal Range

0-123

0-6

0-18

0-22

0-47

0-40

0-43

0-27

0-2

124-

Marginal Range

7

19-27

23-33

48-67

41-55

44-62

28-38

3-4

170

171-

High Range

8-10

28-36

34-44

68-88

56-75

63-81

39-49

5-6

215

Abnormal

216+

11+

37+

45+

89+

76+

82+

50+

7+

Abnormal Trend

(PPM Increase

43

3

7

9

17

15

16

10

2

in 10 hrs)

TECHNICAL INFORMATION

A faulty air induction system is normally a significant source of

silicon in engine oil. Antifoaming agents in engine oil normally

contain silicone which will give 3 to 7 PPM in new oil. Silicone is

used in "Print-O-Seal" cylinder head gaskets and crankshaft seals

for this engine which will normally show 20 to 30 PPM silicon in

the oil. Aluminum and cast iron parts in the engine can have

significant amounts (up to 10%) of silicon in their composition.

Significant wear can be expected on the piston skirts and cylinder

liners for this engine.

The engine is liquid-cooled; therefore, ethylene glycol present in

the engine oil would indicate a leak in the coolant system.

Oil control rings and first compression ring are chrome plated.

(Cr)

Tin

Plating on pistons.

(Sn)

Iron

Wear of cylinder walls. Wear of numerous other engine parts. Also

(Fe)

from machining chips left in engine.

Lead-Tin-Copper

Crankshaft bearings, both connecting rods, and mains. Wear of

(Pb-Sn-Cu)

many bushings, bearings, and thrust washers.

Copper-Lead-Tin-Zinc

Wear of many bushings.

(Cu-Pb-Sn-Zn)

Aluminum-Silicon-

Upper connecting rod bearing shell and No. 7 main bearing

Cadmium

washers.

(Al-Si-Cd)

APPLICABLE END ITEMS

175B, BRIDGE-MA, M107, M108, M109, M109A1, M109A2, M109A3, M110, M110A2, M578, M992, XM1050

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |