|

|||

|

|

|||

|

Page Title:

Continental LD/LDS/LDT 465-1/-2 (Engine) |

|

||

| ||||||||||

|

|

NAVAIR 17-15-50.4

TM 38-301-4

T.O. 33-1-37-4

CGTO 33-1-37-4

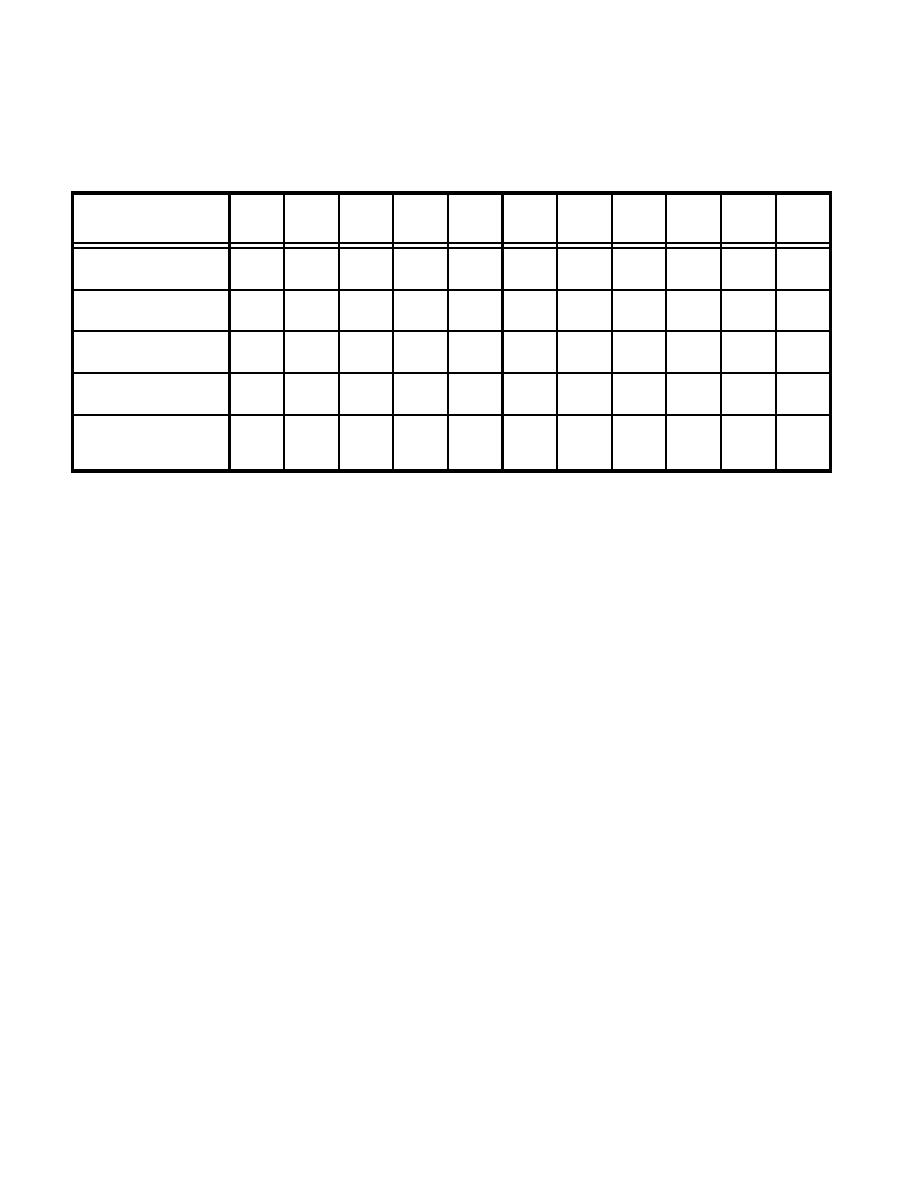

COMPONENT:

Continental LD/LDS/LDT 465-1/-2 (Engine)

LUBRICANT: MIL-L-2104

Fe

Ag

Al

Cr

Cu

Si

Sn

Ni

Pb

Mo

Mg

Normal Range

0-214

0-5

064

0-30

0-51

0-65

0-98

99-

215-

6

65-78

31-36

52-63

66-80

Marginal Range

121

263

122-

81-

264-

7-8

79-98

37-45

64-79

High Range

151

100

329

Abnormal

330+

9+

99+

46+

80+

101+

152+

Abnormal Trend

(PPM Increase

15

2

4

3

4

4

6

in 10 hrs)

TECHNICAL INFORMATION

A faulty air induction system is normally the major source of

silicon in engine oil. Antifoaming agents in engine oil normally

contain silicone which will give 3 to 7 PPM in new oil. Silicone

coatings may also be used in oil-wetted engine parts. Aluminum

and cast iron parts in the engine can have significant amounts (up

to 10.5%) of silicon in their composition.

The engine is liquid-cooled; therefore, ethylene glycol may be

present in the engine oil, indicating coolant contamination.

Piston rings, cylinder sleeves, and pistons normally show the most

significant wear during operation. There is normally some wear of

the rocker arm bearings which would produce trace amounts of

silver (Ag).

Iron particles from both wear and machining are commonly found

in the oil pan.

Chromium

Oil control rings are surface plated with chromium.

(Cr)

Tin

Plating on pistons.

(Sn)

Tin-Iron

Engine pistons and cylinder wall wear.

(Sn-Fe)

Iron

Wear of cylinder walls. Wear of numerous other engine parts. Also

(Fe)

may be from machining chips left in engine.

Nickel-Chromium-

Exhaust valves.

Cobalt

(Ni-Cr-Co)

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |