|

|||

|

|

|||

|

Page Title:

Continental AVDS 1790-2A/2C/2D/ (Engine) |

|

||

| ||||||||||

|

|

NAVAIR 17-15-50.4

TM 38-301-4

T.O. 33-1-37-4

CGTO 33-1-37-4

COMPONENT:

Continental AVDS 1790-2A/2C/2D/ (Engine)

LUBRICANT: MIL-L-2104

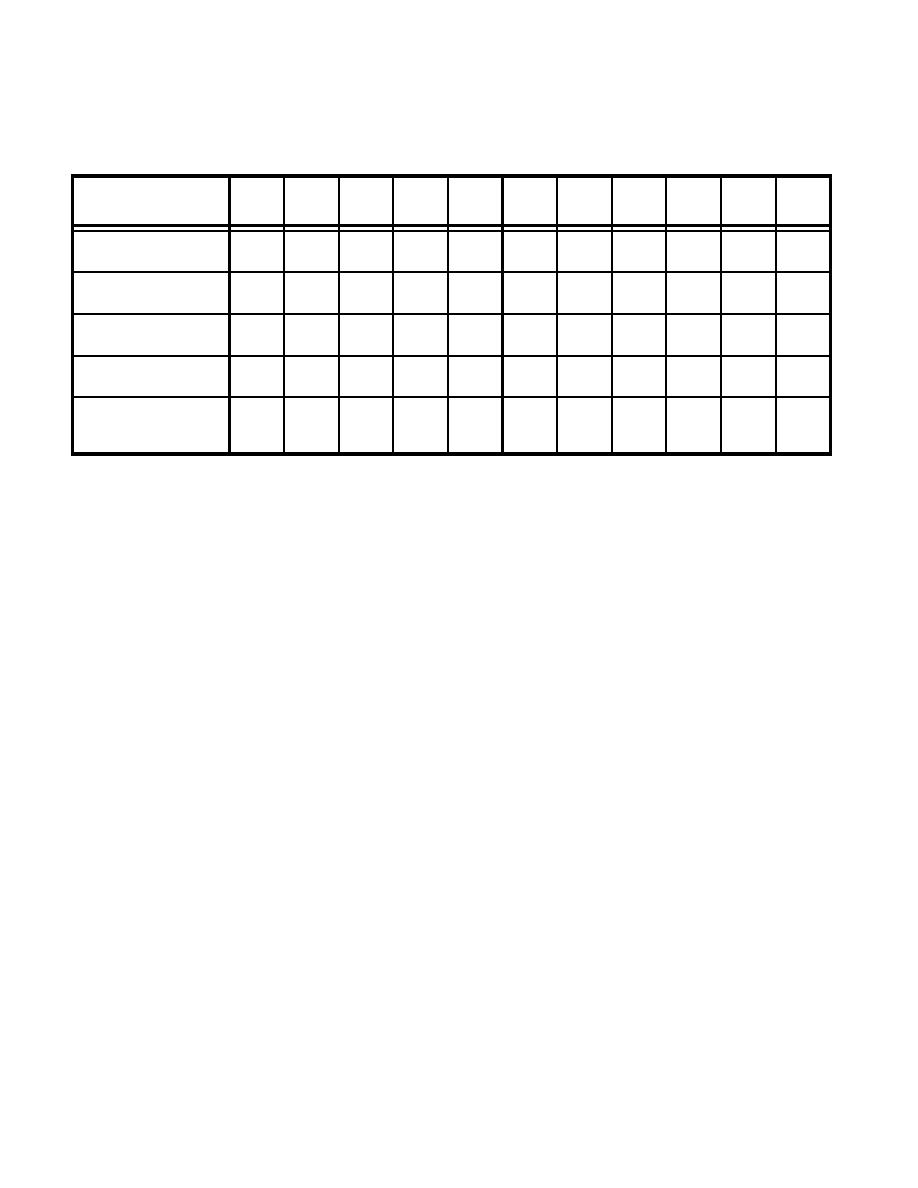

Fe

Ag

Al

Cr

Cu

Si

Sn

Ni

Pb

Mo

Mg

Normal Range

0-99

0-6

0-43

0-10

0-50

0-60

0-8

0-6

0-30

0-14

100-

Marginal Range

7-9

44-63

11-14

51-65

61-85

9-12

7-8

31-42

15-20

145

146-

86-

High Range

10-11

64-82

15-18

66-85

13-15

9-10

43-55

21-26

185

110

Abnormal

186+

12+

83+

19+

86+

111+

16+

11+

56+

27+

Abnormal Trend

(PPM Increase

37

3

16

4

17

22

4

3

11

5

in 10 hrs)

TECHNICAL INFORMATION

The AVDS 1790-2A engines in the field are being modified to

AVDS 1790-2D. AVDS-1790-2C/2D/2/DR engines are classified

as Reliability Improvement Selected Equipment (RISE) versions of

the engine. The RISE engines retain 10 gallons less residual oil

after oil drain than the unmodified engines.

A faulty air induction system is the major source of silicon in

engine oil. Silicone coatings may also be used in oil-wetted engine

parts. Aluminum and cast iron parts in the engine can have

significant amounts (up to 13.5%) of silicon in their composition.

When the rear main seal in an AVDS 1790 engine attached to a

CD 850-6A transmission wears excessively or ceases to function

properly, there will be cross-contamination of the engine and

transmission lubricants. This, in general, will be indicated by

increasing or high copper (Cu) and lead (Pb) in the engine oil

samples and, simultaneously, increasing or high molybdenum

(Mo) in the transmission oil samples.

The engine is air-cooled; therefore, no

liquid

coolant

contamination problems should be experienced.

Aluminum and iron particles from both wear and machining are

commonly found in the oil pan.

Aluminum-Silicon

Piston wear or piston and cylinder wall wear. Could also be derived

(Al-Si)

from machining chips left in engine.

Iron

Wear of cylinder walls. Wear of numerous other engines parts. Also

(Fe)

from machining chips left in engine.

Oil control rings are surfaced plated with chromium.

(Cr)

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |