|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

NAVAIR 17-15-50.4

TM 38-301-4

T.O. 33-1-37-4

CGTO 33-1-37-4

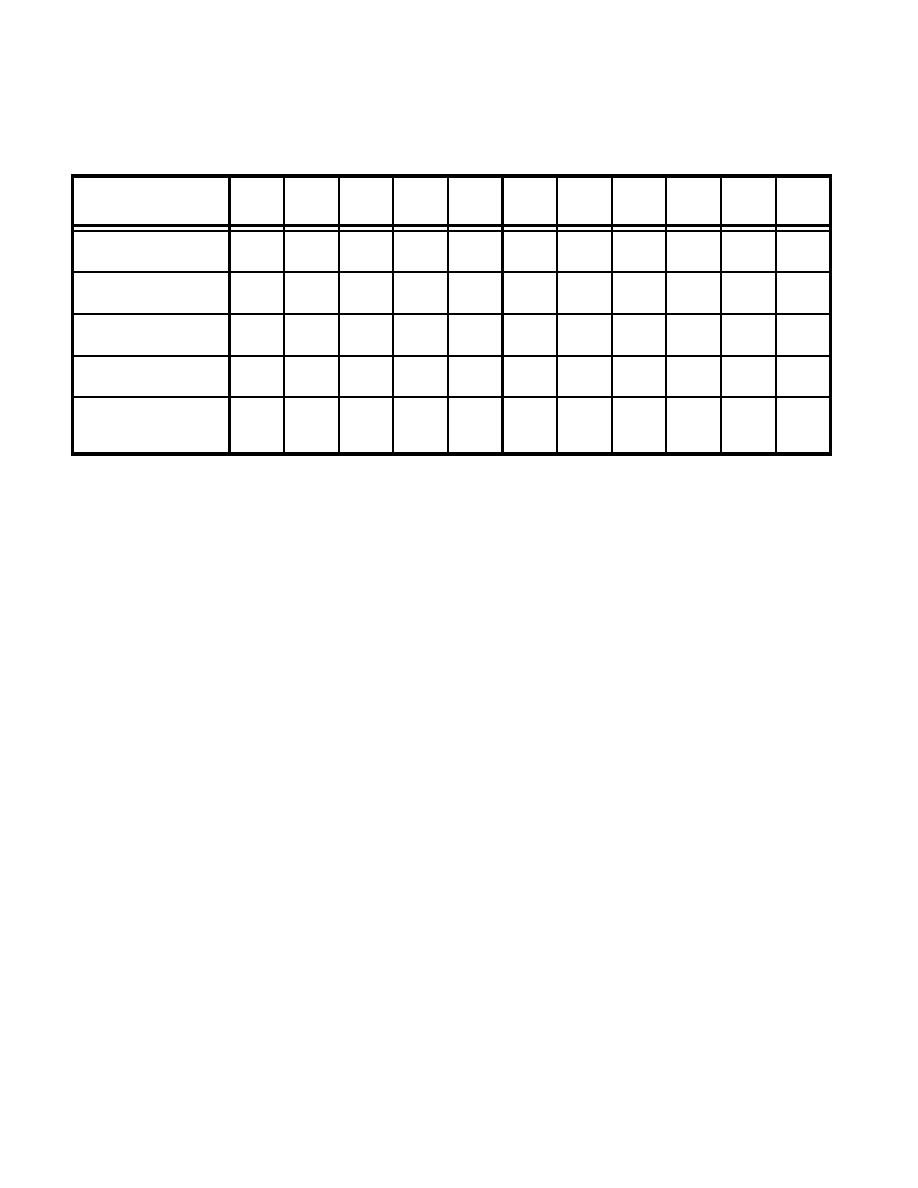

COMPONENT:

Caterpillar D343T/A (Engine)

LUBRICANT: MIL-L-2104

Fe

Ag

Al

Cr

Cu

Si

Sn

Ni

Pb

Mo

Mg

Normal Range

0-40

0-9

0-2

0-15

0-15

5-25

Marginal Range

41-65

10-15

3-6

16-25

16-23

26-40

High Range

66-90

16-18

7-10

26-50

24-30

76+

Abnormal

91+

19+

11+

51+

31+

76+

Abnormal Trend

(PPM Increase

18

4

3

10

6

15

in 10 hrs)

TECHNICAL INFORMATION

A faulty air induction system is normally the major source of silicon in

the engine oil. Antifoaming agents in engine oil normally contain

silicone which will give 3 to 7 PPM in new oil. Silicone coatings may

also be used in oil-wetted engine parts. Aluminum and cast iron parts in

the engine can have significant amounts of silicon in their composition.

If the engine is in operation only occasionally, it may show a

significant increase in iron (Fe) wear particles during operation caused

by rust of components. Operation during cold and warm periods of the

year makes a difference in the concentration of wear particles. When it

is cold, the copper values become higher due to an increase of water in

the oil caused by condensation. In cold weather there may also be an

increase of iron, chromium, lead, and aluminum wear particles caused

by increased wear from starting the engine.

The engine is liquid-cooled; therefore, ethylene glycol may be present

in the engine oil, indicating coolant contamination.

Lead (Pb) is normally generated at relatively high levels during the

break-in period of the engine, and then remains fairly constant except

for heavy loading, marginal lubrication, or excessive dirt. Increase lead

can be the first symptom of bearing distress.

APPLICABLE END ITEMS

290M, 830MB, MEP-009A, MEP-108A

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |