|

|||

|

|

|||

|

Page Title:

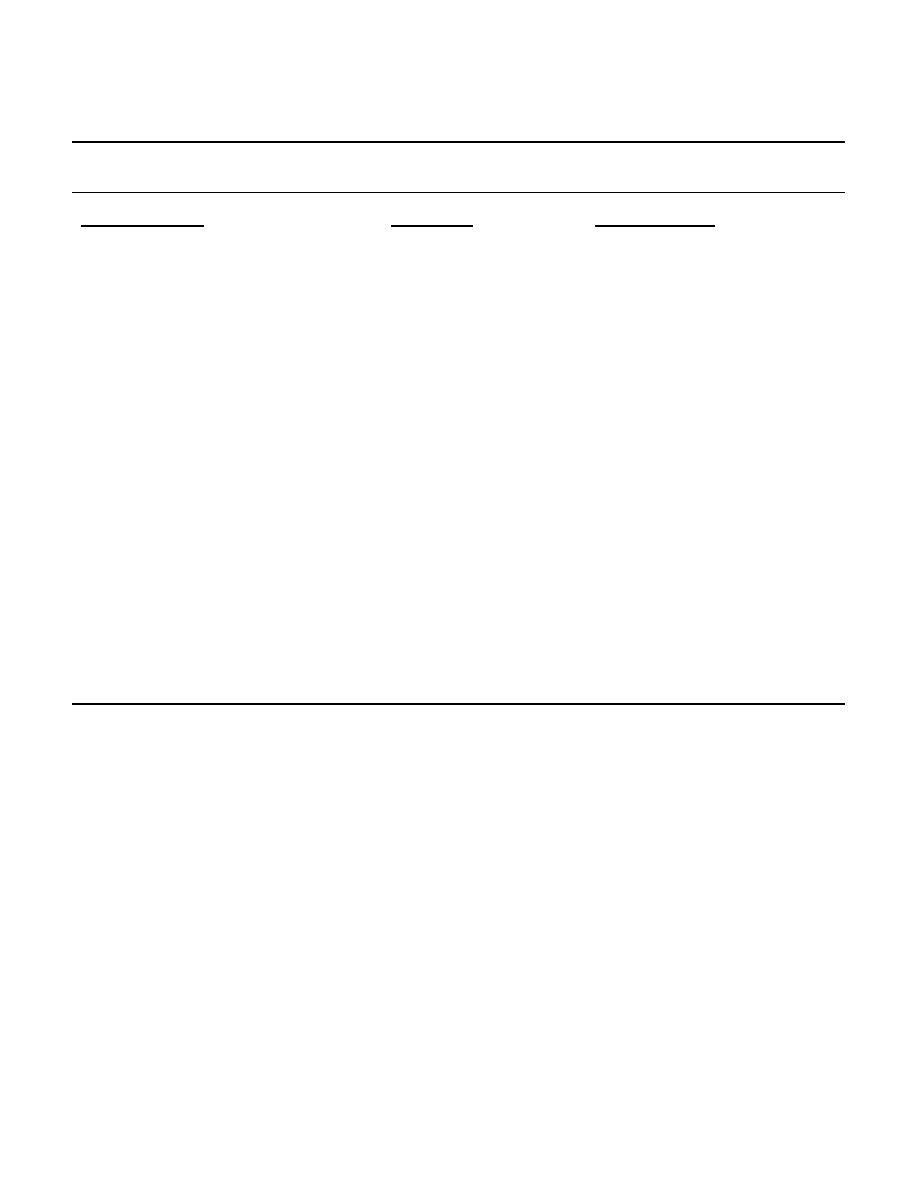

TABLE 2-3. LUBRICANT CONTAMINANTS |

|

||

| ||||||||||

|

|

NAVAIR 17-15-50.4

TM 38-301-4

T.O. 33-1-37-4

CGTO 33-1-37-4

Contaminant Type

Significance

Analytical method

System wear

Wear-metals

Spectrometer

Emulsifies oil, impairs

Coolant

Crackle test; blotter

lubrication, destroys

spot; spectro for

dispersant additives

Na, B

Corrosion, emulsifies

Free Water

Crackle test; blotter

Oil, impairs lubrication

spot; spectro for

Na with Marine

equipment, visual

inspection

Lowers oil viscosity

Fuel

Viscosity; Alkalinity Test

Causes abrasive wear

Dirt, sand

Spectro for Si, Al;

blotter spot;

visual inspection

Increases viscosity,

Blow-by products,

Viscosity; blotter spot

forms sludge

Soot

Corrosion, viscosity increase

Reactive compounds

Viscosity; Alkalinity Test

Internal Corrosion

Rust

Spectro for Fe

NOTE

A request for a sample of the new oil from stock is desirable whenever an increase in

an element is suspected to be the result of additives from an oil addition.

Spectrometric results should also be evaluated for foreign contamination such as ingested dirt, evidenced by high

silicon or aluminum, or engine coolant leakage, evidence by increases in sodium and boron. Additive levels may

be shown by spectrometric data for elements such as zinc, boron, magnesium, or sodium.

(2) Viscosity guidelines for MIL-L-2104, the oil most commonly used in the Nametre viscometer.

Viscosity results below minimum guidelines indicate the sample should be tested for fuel dilution. Viscosity results

above maximum guidelines indicate the sample should be tested for total contaminants by blotter test and for

water by crackle or Karl Fischer. Alkalinity should also be checked because low alkalinity means acids are being

produced which are depleting the alkaline additives in the oil. These acids can form products which increase the

viscosity. Viscosities for oils other than MIL-L-2104 should be evaluated by comparing the viscosity of the used oil

sample to the viscosity of a sample of the new oil.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |