|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

NAVAIR 17-15-50.3

TM 38-301-3

T.O. 33-1-37-3

CGTO 33-1-37-3

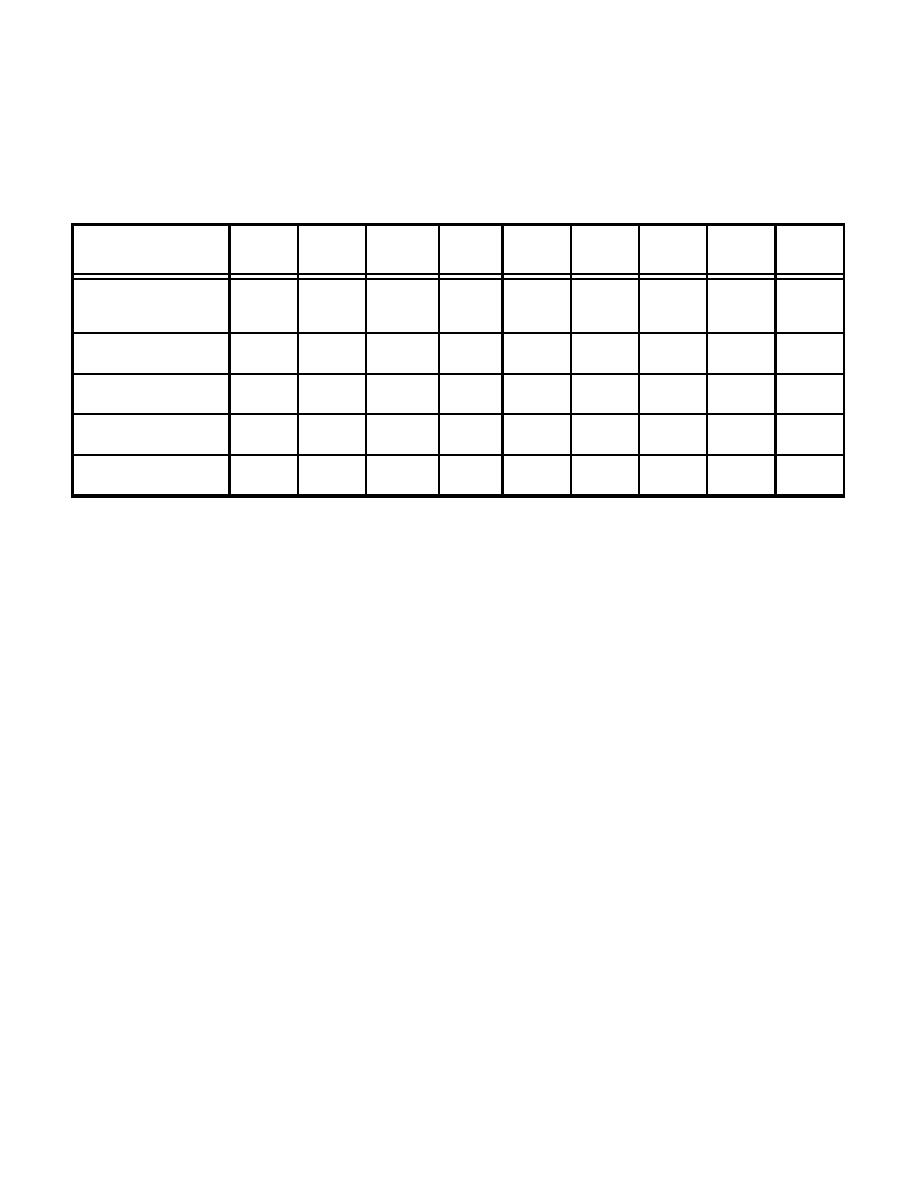

MH-60A/UH-60L/MH-60L/MH-60K (U.S. ARMY ONLY)

TAIL ROTOR GEARBOX

JOAP ATOMIC EMISSION ROTRODE

Fe

Al

Cu

Ag

Mg

Ti

Cr

S

Abnormal Trend

(PPM Increase

9

**

**

3

9

3

in 10 hrs)*

Normal Range

0-36

0-5

0-75

0-2

0-26

0-4

Marginal Range

37-41

**

**

3

27-32

5

High Range

42-45

**

**

4

33-40

6

Abnormal

46+

**

**

5

41

7+

Average Concentration Other Elements:

*

If the calculated PPM trend value is equal to or greater than the trend PPM value limit, the engine has an

abnormal trend.

**

For use of Al and Cu wear metal concentrations, see paragraphs 5b and 5e respectively.

NOTE

The following information is provided to assist oil analysis laboratory personnel in

determining tail rotor gearbox condition based upon an analysis of the gearbox

lubricant. The following information does not cover every possible wear mode or

operational characteristic. The information is intended to assist the lab personnel in

making a determination of the health of the gearbox. If a situation exists that is not

covered by the following information, or if additional information or clarification of

existing information is desired, contact ATCOM Engineering, AMSAT-R-EPD, at DSN

693-1597.

1. The BLACK HAWK tail rotor gearbox changes the speed and angle of drive from the tail drive shaft to the tail

rotor blades and pitch control mechanism. See Figure A-1. The major components of the tail rotor gearbox include

the housings (input, center, and output), the input bevel pinion and the output bevel gear, four (4) tapered roller

bearings, an input flange, an inboard retention plate, and input and output seals. See Figure A-2 for the location of

the major components. The tail rotor gearbox is operated with the tail rotor servo and pitch control shaft installed

into the gearbox. See Figure A-3.

2. The tail rotor gearbox utilized a self-contained splash-type lube system without an oil filter. Normal wear

particles will increase in number until the gearbox is drained and flushed. Either DOD-L-85734, MIL-L-23699, or

MIL-L-7808 lubricant is used in the gearbox. The gearbox contains approximately 2.75 pints of lubricant. The

gearbox lubricant is replaced every 500 flight hours.

a. MIL-L-23699 is the most common lubricant in use in the field. It is being replaced by the DOD-L-85734

lubricant, which is now the primary lubricant. DOD-L-85734 lubricant is similar to MIL-L-23699 (e.g., it has the

same viscosity), but has the addition of EP (Extreme Pressure) additives to improve its performance with loaded

gear meshes. Field units should notify the lab if a change to DOD-L-85734 lubricant in order to establish a

baseline for this lubricant. Establishment of a baseline is essential in analyzing tail rotor gearboxes using the

DOD-L-85734 lubricant. MIL-L-7808 lubricant will continue to be used for cold-weather operation.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |