|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

NAVAIR 17-15-50.3

TM 38-301-3

T.O. 33-1-37-3

CGTO 33-1-37-3

ENGINE: IO-360-C/D

AIRCRAFT: (0-2) (0-3)

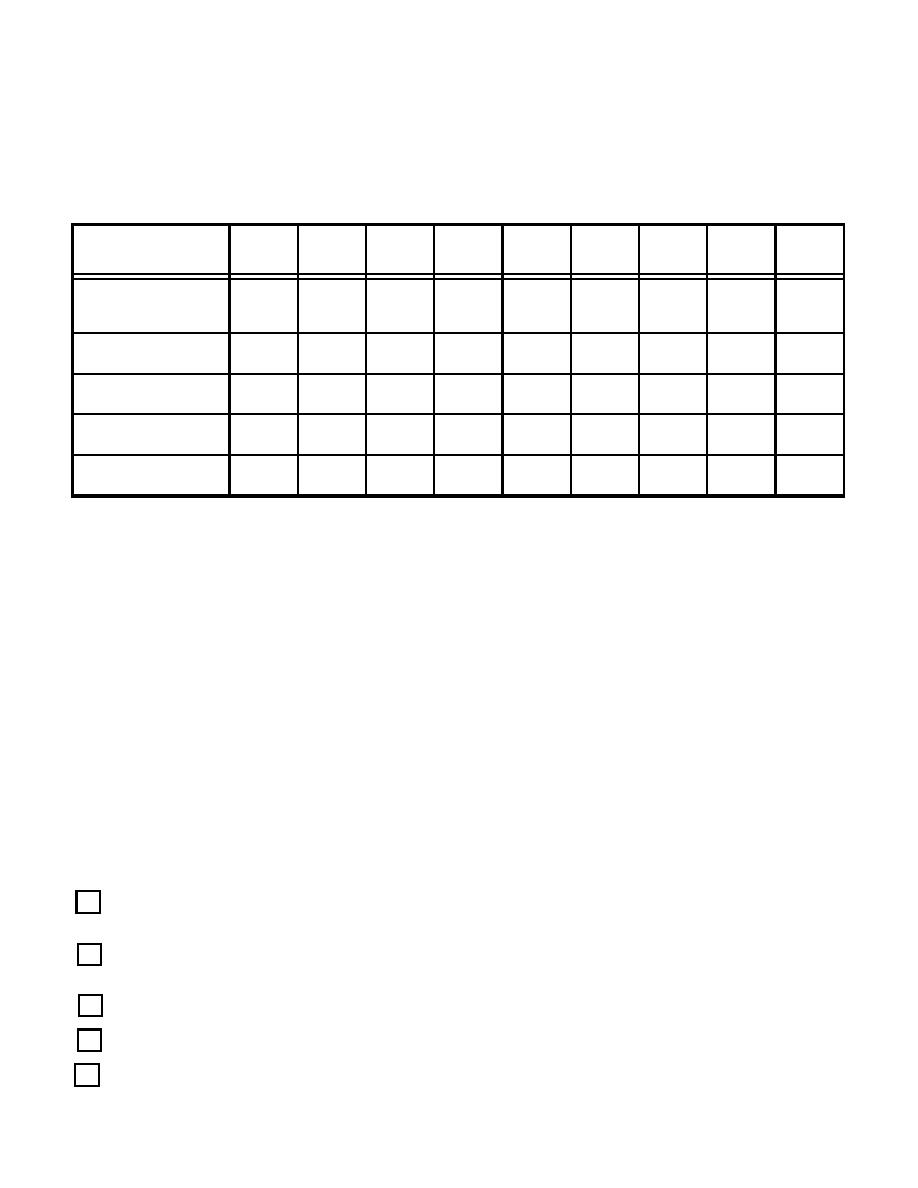

JOAP ATOMIC EMISSION ROTRODE

Fe

Ag

Al

Cr

Cu

Mg

Abnormal Trend

(PPM Increase

28

3

11

4

8

4

in 10 hrs)*

Normal Range

0-91

0-6

0-36

0-13

0-26

0-13

Marginal Range

92-112

7

37-44

14-16

27-32

14-16

113-

High Range

8-9

45-54

17-19

33-39

17-19

139

Abnormal

140+

10+

55+

20+

40+

20+

Average Concentration Other Elements:

Ni=5

Pb=870

Si=8

Sn=4

Ti=1

Mo=2

* If the calculated PPM trend value is equal to or greater than the trend PPM value limit, the engine has an

abnormal trend.

Increases in Fe and Cr are indicative ring/cylinder wear. Increase in Cu by itself, or in combination with Fe,

indicates rod and main bearing discrepancy.

NOTE

O-series engines are "wet sump" (oil pan) type engines and oil tank capacity is small.

This causes tendency for sample contamination. Frequent oil change interval (50

hours) must be considered when evaluating JOAP results. An orange colored band at

the cylinder base indicates chrome plated barrels. Engines thus equipped should be

expected to produce high chrome wear metal during break-in period (up to 150 hours),

but should decrease and stabilize thereafter. Laboratory personnel should inquire

whether engines producing high chrome wear metals are equipped with chrome plated

cylinders, and base maintenance recommendations upon this knowledge.

Fe

Push rods, camshaft, cylinder barrels, rocker arms, crankshaft, valve lifters, valve

springs, washers.

Fe

Ni +

Cr

Oil pump gears, crankshaft cluster gear, governor drive gears, camshaft gears,

piston rings

Cu

Pb +

Sn

Valve rocker bushings, accessory drive bushings, main bearings, connecting rod

Cu

Sn +

Zn

Valve guides, piston pin bushings

Fe

Cr Ni

Valves

Si + W

Al

Cu Ni +

Mg

Mg

Cu +

Al

Crankcase rear cover

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |