|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

NAVAIR 17-15-50.3

TM 38-301-3

T.O. 33-1-37-3

CGTO 33-1-37-3

ENGINE:

F119-PW-100A

AIRCRAFT:

(F-22)

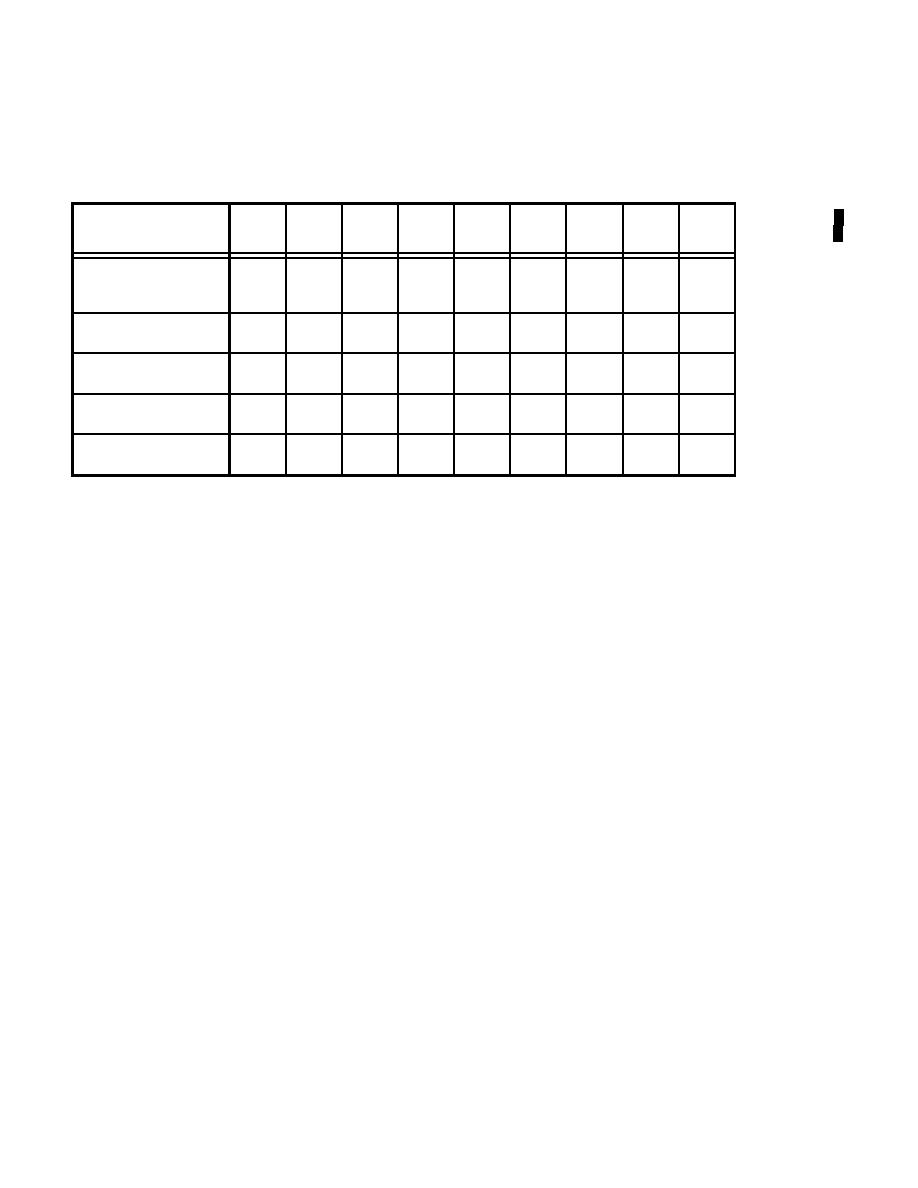

JOAP ATOMIC EMISSION ROTRODE

Ti

Si

Fe

Ag

Al

Cr

Cu

Mg

Ni

Abnormal Trend

(PPM Increase

3

2

3

2

3

2

2

3

N/A

in 10 hrs)*

Normal Range

0-5

0-2

0-5

0-4

0-4

0-4

0-4

0-5

0-10

Marginal Range

6-7

N/A

6-7

5

5-7

5

5

6-7

N/A

High Range

8-9

3

8-9

6

8-9

6

6

8-9

N/A

Abnormal

10+

4+

10+

7+

10+

7+

7+

10+

10+

Average Concentration Other Elements:

Pb=5

Sn=9

Mo=1

Zn=2 Na=2

(A contamination run is recommended if average concentration values are exceeded)

F-119 decision making guidelines:

1. Teardown maintenance for the F-119 is directed within the F-22 integrated maintenance information system

(IMIS) by advanced engine failure resolution (AEFR). engine JOAP data should be loaded into the IMIS database

via the JOAP history window accessed from the IMIS desktop. the AEFR trending function will analyze the JOAP

data and set a failure report code (FRC) for any abnormal trend or limit exceedances. JOAP FRCs are then

utilized to create a JCN directing the appropriate engine teardown maintenance.

2. Any sample value which requires the engine to be placed under surveillance or requires teardown shall be

confirmed by a reburn. Only the reburn sample values shall be loaded into the IMIS database. Proper engine

personnel shall be notified immediately.when an engine is put on surveillance, request for oil filter and chip

detector inspection will be made. when an engine is on surveillance, all chip detectors are to be checked each

time an oil sample is taken.

3. When a F-119 engine is on surveillance, oil samples must be drawn after each flight and analysis results must

be known before the next flight. all chip detectors must be checked each time a sample is drawn. During ground

or test cell operation of an engine on surveillance, oil samples must be drawn at intervals no longer than one hour

total operating time. after an oil sample is drawn, the engine may not be run for more than one hour before oil

analysis results are available.

4. The main engine bearing may fail without indication reflected in the JOAP analysis. Spalling of these bearings

is detected by chip detectors.

5. Engine teardown or surveillance is required for any of the following:

a. Any wearmetal exceeds the abnormal limit. teardown is required.

b. Wearmetal increase by the value of their abnormal trend within a 10 hour engine operating period (total

operating time).surveillance is required for a 10 hour total operating time period.

c. While on surveillance for Fe, Fe increases above the value that caused surveillance by any amount.

teardown is required.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |