|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-20-2

16-8. HOOD ADJUSTMENT

This task covers:

a. Adjustment

b. Follow-On Maintenance

INITIAL SETUP

Equipment Conditions

Materials/Parts

Engine shut off (TM 9-2320-360-10).

Adhesive-Sealant (Item 6, Appendix C)

Parking brake on (TM 9-2320-360-10).

Locknuts (4) (Item 58, Appendix G)

Wheels chocked.

Locknuts (2) (Item 72, Appendix G)

Engine hood opened (TM 9-2320-360-10).

Lockwashers (4) (Item 101, Appendix G)

Lockwashers (2) (item 102, Appendix G)

Tools and Special Tools

Tool Kit, Genl Mech (Item 54, Appendix F)

Wrench, Torque, 0-175 Lb-Ft (Item 73,

Wrench, Torque, 0-200 Lb-In. (Item 72,

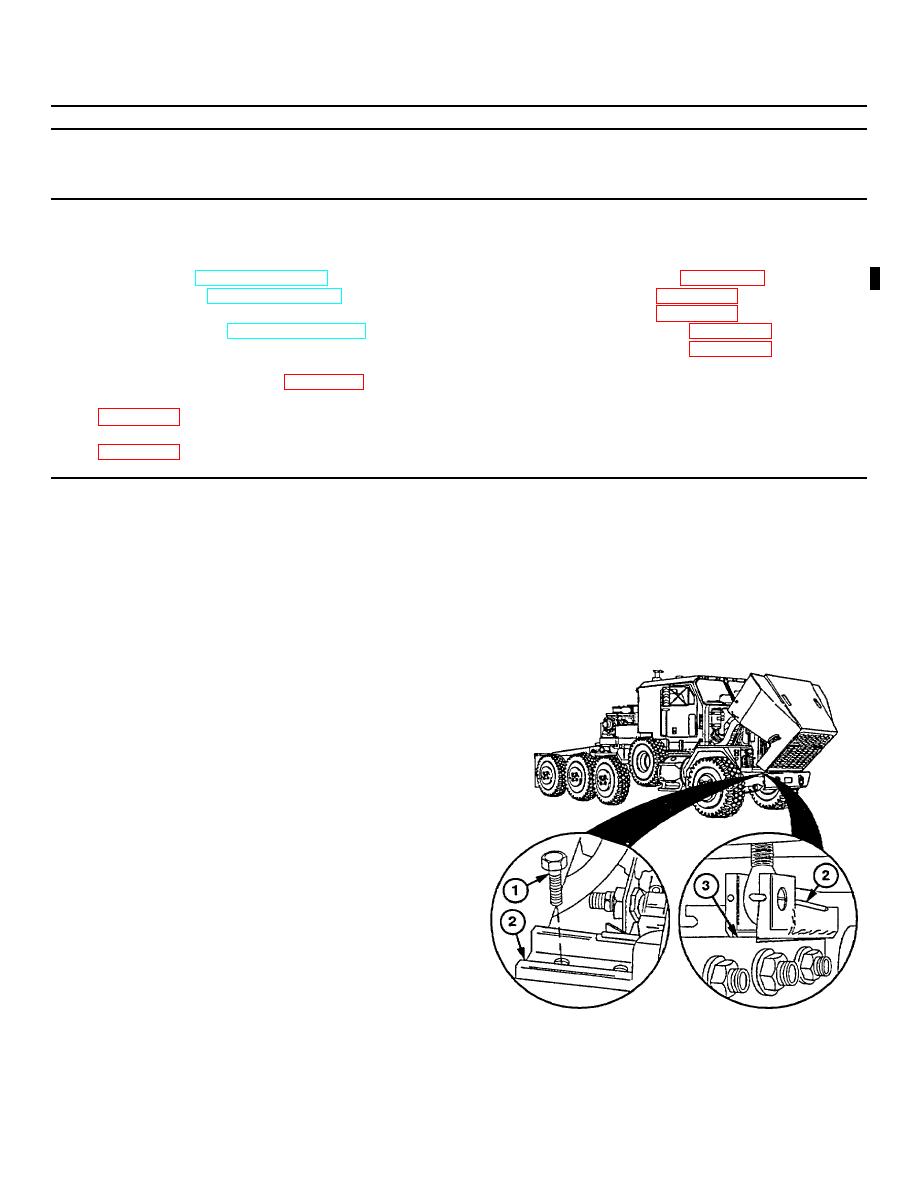

NOTE

To adjust hood position from front to rear, do steps (1) thru (5).

To adjust hood side support, do steps (6) thru (11).

To adjust hood position up or down at bumper, do steps (12) thru (15).

To adjust hood position up or down at cab, do steps (16) thru (20).

When hood is adjusted properly, it should be 1.5 in. (38 mm) above front fenders

and 1.5 in. (38 mm) from cab.

a. Adjustment

CAUTION

Do not attempt to adjust both hinge

brackets at the same time. Failure to

comply will result in hood being

unsupported. Damage to equipment

may result.

(1) Remove two screws (1) from bracket (2).

NOTE

Do not push hood bracket back more

than 0.5 in. (13 mm). Mounting screw

cannot be tightened if hood bracket

is pushed back too far.

(2) Position bracket (2) 0.5 in. (13 mm) from

machined lip (3).

Change 1 16-27

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |