|

|||

|

|

|||

|

Page Title:

SECTION 2 CONTAINMENT PROCEDURES FOR CHEMICAL MUNITIONS |

|

||

| ||||||||||

|

|

TM 9-1300-275/3

SECTION 2

CONTAINMENT PROCEDURES FOR CHEMICAL MUNITIONS

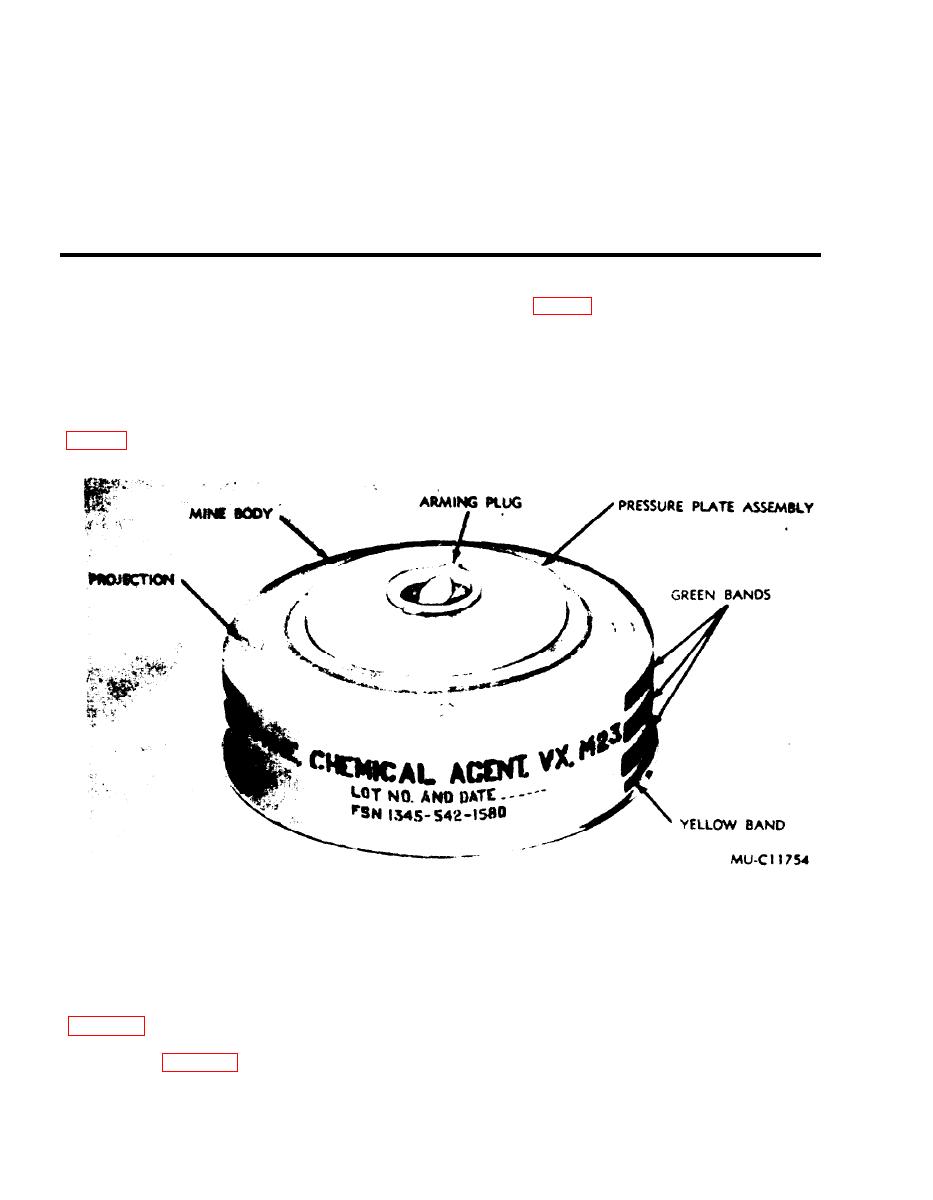

2-1 M23, VX CHEMICAL AGENT MINE.

2-1.2 Arming Plug and Fuze Wells.

This plug (fig. 2-1), in the top-center of the mine,

2-1.1 Identification.

must always be set at SAFE (fig. 2-2). The side

The M23 chemical mine, a D.O.T. Class A ex-

and bottom-center of the mines each have a

plosive/poison, is 13 inches in diameter and 5

secondary fuze well (fig. 2-3). Activators (fig.

inches high. It is the same as the M15 high-

2-4) that adapt these wells to firing devices are

explosive mine, except for the one yellow and

shipped with the mine in cans similar to those

three green bands, and the four sets of projections

for the fuzes.

equally spaced around the top of the mine body

Figure 2-1. M23 Chemical Mine.

2-1.3 Shipping Configuration.

2-1.4 Hazards.

Normally, the shipping configuration for the M23

a. Chemical agent leaking from seams, fuze,

chemical mine consists of a pallet of steel drums.

or fuze wells.

Each drum holds three mines. The top cushion

b. The explosive fuze.

c. Explosive bursters within the mine.

cans, all the same size. Half these cans contain

d. The explosive activator.

M603 fuzes (fig. 2-6); the other half, Ml acti-

2-1.5 Principles of Operation.

vators. The drums are palletized or crated.

The M23 chemical mine is prefilled with a nerve

4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |