|

|||

|

|

|||

|

Page Title:

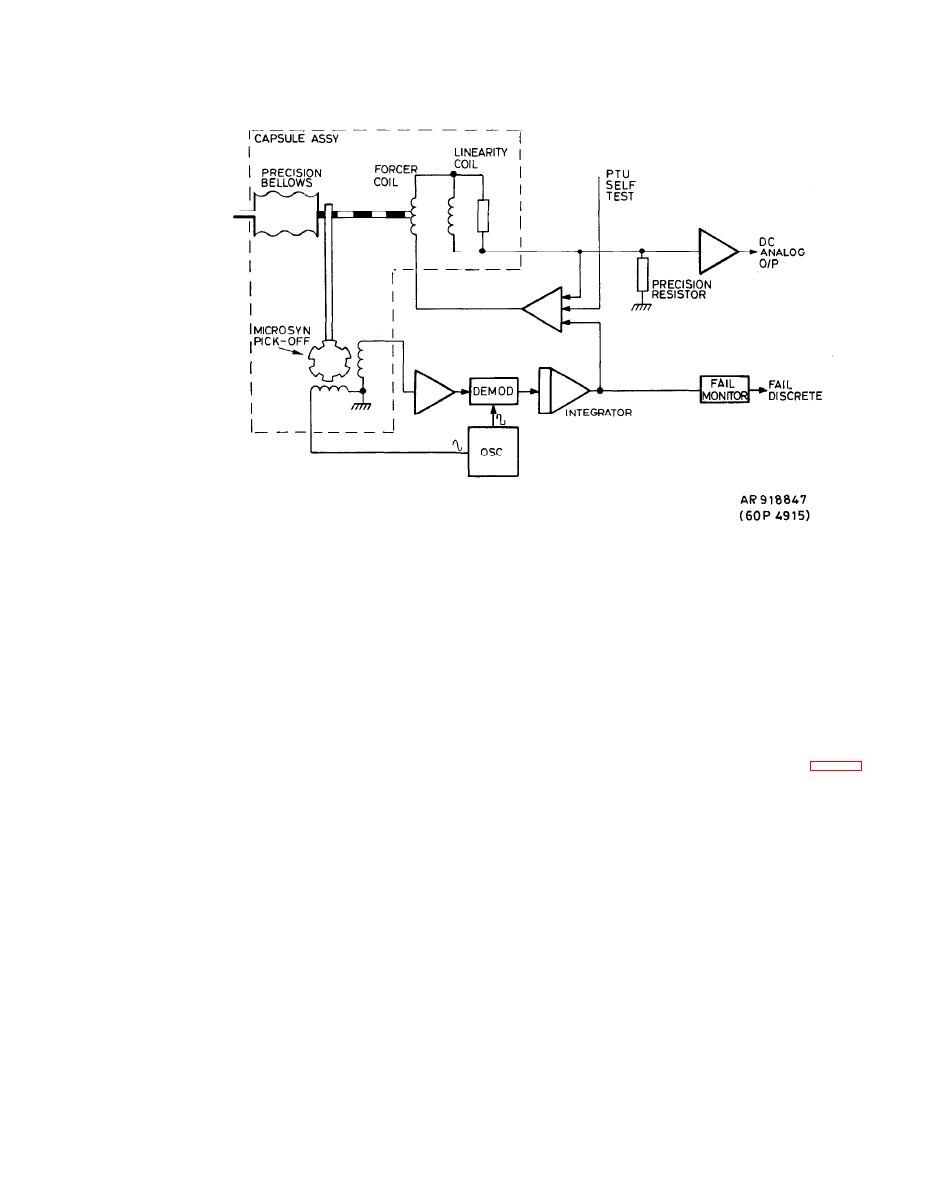

Figure 1-19. Transducer Control Block Diagram. |

|

||

| ||||||||||

|

|

TM 9-1270-219-13&P

by the demodulator and the resulting error signal is integrated

(c) Temperature correction is effected digitally by

the CPU by reference to the temperature-sensing coil in the

and used to drive the power transistors. These supply the

transducer and the temperature characteristic which is

current

for

the

forcer

coil

to

correct

the

bellows

stored in a unique PROM mounted on the PTU circuit

attempted movement. A precision resistor is used to sense

board.

the

amount

of

current

required,

and

the

output

is

b u f f e r e d before being presented as a dc analog of the

pressure sensed by the bellows. The output buffer is also

b. Central Processor Unit (CPU). The CPU (fig. 1-20)

used to sum-in corrections for the transducer's nominal

is based on a 16-bit microprocessor which has separate

offset and gain.

address and data buses and can interface with standard

TTL and MOS components. The CPU also includes a 3K x

16 Programmable Read Only Memory (PROM), 256 x 16

(3) Temperature Correction. Both transducers exhibit

Random Access Memory (RAM), a clock generator, timer,

temperature sensitivity which causes repeatable

datum

D/A converter, input and output interface ports, and a

and gain shifts.

serial 64-bit buffer for interface to the FCC. Data is

transferred

between

the

memory

and

memory-mapped

i n p u t / o u p u t interfaces via a 16-bit data bus, and memory

addresses are decoded from a 15-bit address bus. The

(a) Datum shift occurs between the pick-off null

microprocessor runs at a 2MHz clock rate.

relative to the mechanical null, causing repeatable

non-linear characteristics in each transducer.

(1) M e m o r y . Program and fixed data constants are

stored

in

six

1024

x

8

PROMS.

Pressure

transducer

characterization constants are stored in two 32 x 8

P r o g r a m m a b l e Read Only Memories (PROMS) located on

(b) Gain shifts are a function of the permanent

the PTU and linked to the CPU by the 16-bit data bus and

magnetic field strength and are repeatable for each

five lines of the address bus.

transducer.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |