|

|||

|

|

|||

|

Page Title:

CHAPTER 2 DIRECT AND GENERAL SUPPORT MAINTENANCE INSTRUCTIONS |

|

||

| ||||||||||

|

|

CHAPTER 2

DIRECT AND GENERAL SUPPORT

MAINTENANCE INSTRUCTIONS

Section I. REPAIR PARTS, SPECIAL TOOLS AND EQUIPMENT

2-1. Special Tools and Equipment

2-2. Direct and General Support Maintenance Repair

No special tools or equipment are required by direct and

Parts

general support maintenance personnel for performing

Direct and general support maintenance repair parts are

maintenance on the substation.

listed and illustrated in TM5-6120-250-34P.

Section II. TROUBLESHOOTING

mobile substation and its components. Malfunctions

WARNING

which may occur are listed in tables 2-1 through 2-4.

Each malfunction stated is followed by a probable cause

Before inspection or any maintenance work is

and recommended corrective action.

performed, all electrical power should be

disconnected, both the source and load.

2-4. Load Break Switch Troubleshooting

2-3. General

malfunctions for direct and general support maintenance

This section provides information useful in diagnosing and

personnel.

correcting unsatisfactory operations or failure of the

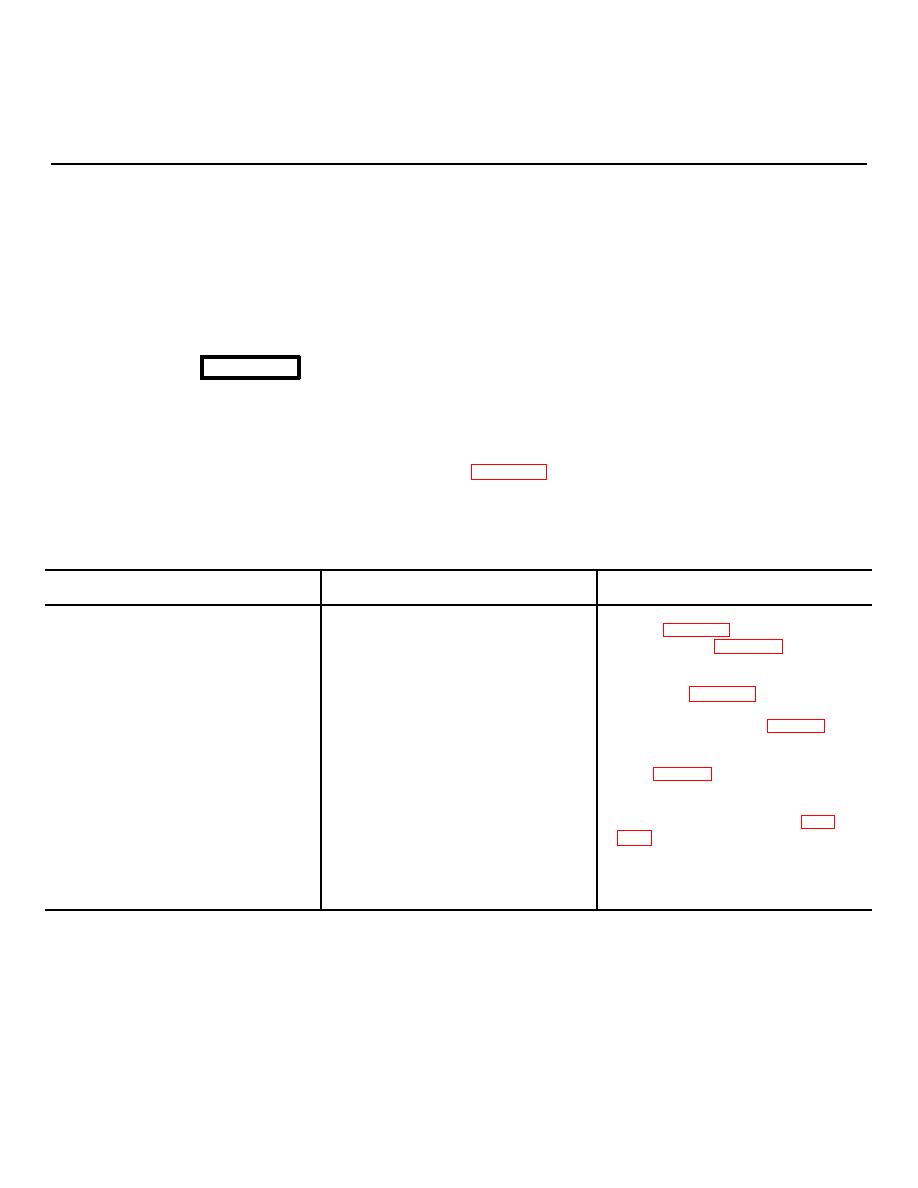

Table 2-1. Load Break Switch Troubleshooting

Malfunction

Probable Cause

Corrective Action

1.

Overheating.

a. Adjust (para 2-14).

a. Contact not aligned.

b. Contacts dirty, greasy, or coated

with dark film.

c. Contacts badly burned or pitted.

c. Replace contacts and adjust

movement (para 2-14).

d. Connection to switch terminals

d. Tighten, but do not exceed elastic

not tight.

limit of bolts and nuts. (table 1-1).

2.

Operates Hard.

a. Switch loose on mounting frame

a. Tighten mounting bolts, but do

allowing it to twist.

not exceed elastic limit of bolts and

nuts (table 1-1).

b.

Switch movement loose.

b. (Check all nuts, washers, bolts,

cotter pins for tightness. Check for

binding or excessive friction. (para

c.

Mechanisms dry.

and other moving parts for need of

lubrication or dry hardened old

malfunctions

for direct

and

general

support

2-5.

Transformer Troubleshooting

maintenance personnel.

Table

2-2 lists the transformer

troubleshooting

2-1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |