|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

NAVAIR 17-15-50.3

TM 38-301-3

T.O. 33-1-37-3

CGTO 33-1-37-3

MH-60A/UH-60L/MH-60L/MH-60K (U.S. ARMY ONLY) (Cont.)

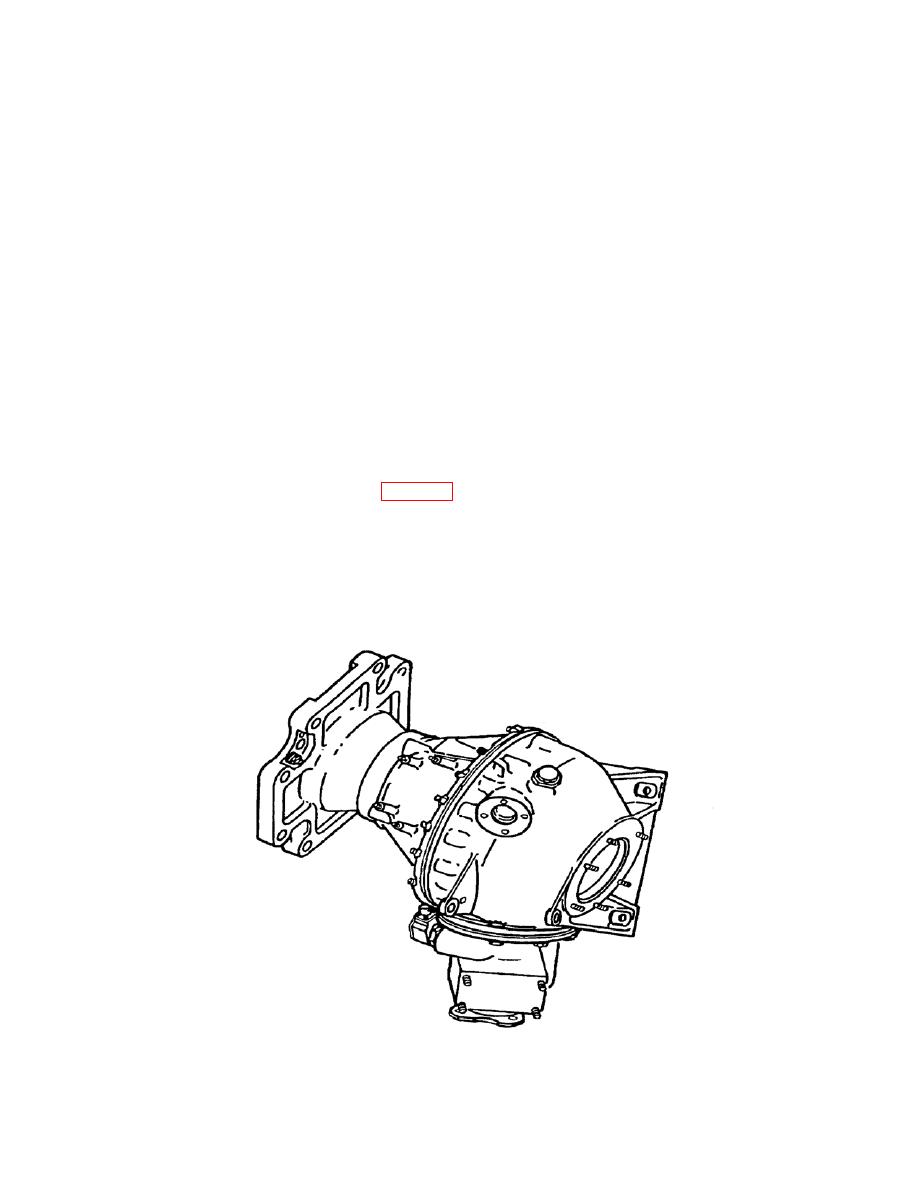

TAIL ROTOR GEARBOX

b. When used in gearboxes which had been operated with MIL-L-23699 or MIL-L-7808 lubricant, the

DOD-L-85734 lubricant has a detergent effect. This may cause an increase in wear metal levels as seen in

spectrometric analysis of oil samples. Lab personnel should use caution when analyzing oil samples in these

cases, as the increase in wear metal levels

may give the same indications that component wear would give. After gearboxes which have changed to DOD-L-

85734 have operated for 50 - 100 flight hours, have the unit perform a drain and flush to remove wear metals from

the gearbox.

c. Oil analysis laboratory personnel should not hesitate to request a drain and flush of the tail rotor

gearbox if they believe it is warranted. Removal of contaminants and wear particles from the gearbox lubricant is

the best method to prolong gearbox life and prevent future problems. Drain and flush procedures are given in

paragraph 7 below.

3. Oil analysis lab personnel may receive oil samples either from a regular interval sampling, or whenever the

field unit experiences a problem with the tail rotor gearbox on their aircraft. The regular sampling interval is now

50 flight hours. The most common cause for field units to send a special sample to the oil analysis laboratory is

when there are chips present in the gearbox. Table A-1 gives the chip evaluation criteria for tail rotor gearboxes.

This criteria may be used by laboratory personnel to assist in the evaluation of the condition of a tail rotor gearbox

from which chips were identified.

4. All oil samples submitted for analysis should be checked for water contamination. The limit is 1000 ppm or

0.100%. Gearboxes with water contamination should be drained and flushed per paragraph 7 below in an attempt

to prevent gearbox housing corrosion. See paragraph 6b for further information.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |