|

|||

|

|

|||

|

Page Title:

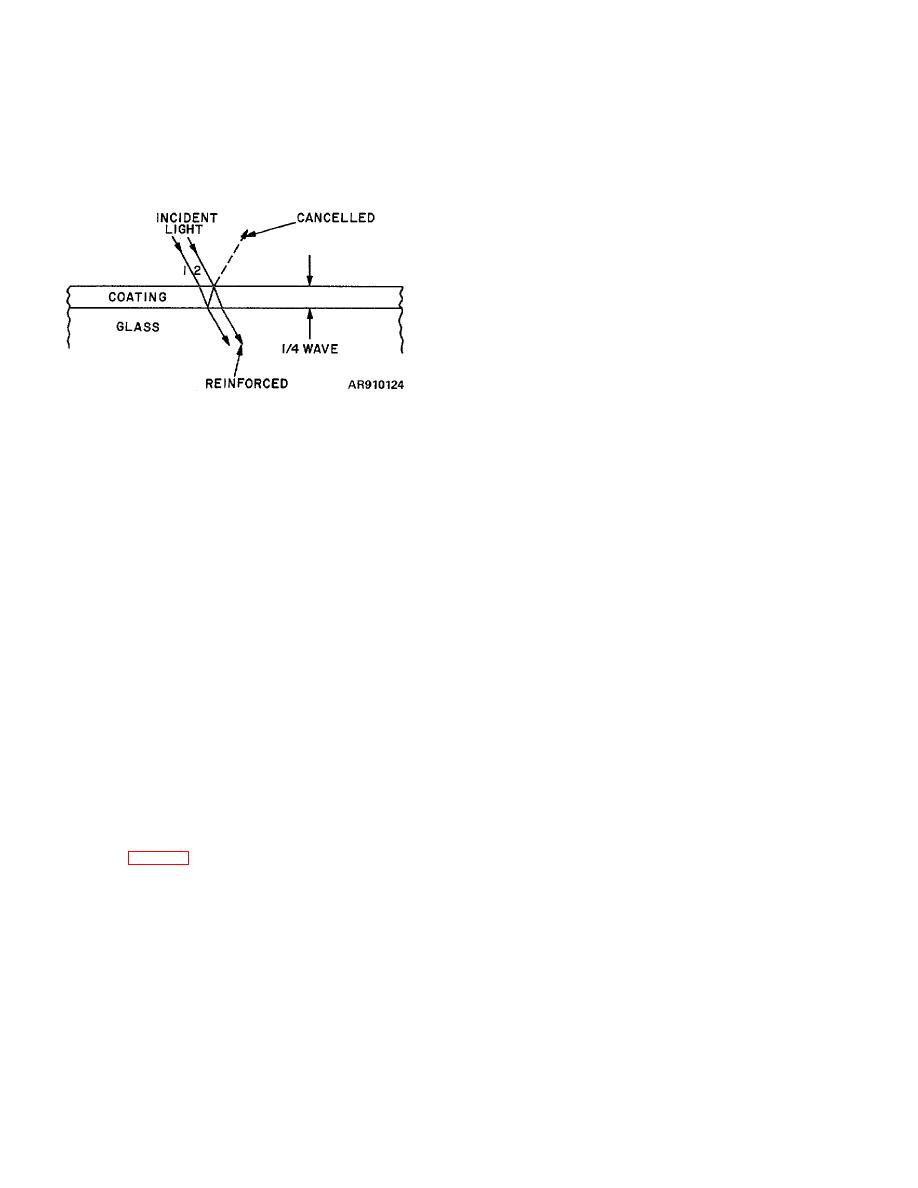

Figure 4-34. Low-reflectance coating. |

|

||

| ||||||||||

|

|

TM 9-258

phase shift previously mentioned however, the oncoming

the reflections from the eyepiece and objective end

wave in ray 2 coincident (at the air-to-film interface) with

surfaces. If the optical elements in the instruments are

the wave from ray 1 (reflected from film-to-glass

coated, the reflection of light will have a distinctive

interface) i will be in phase. Reinforced transmission of

purplish tinge. Under certain conditions, the faces of

ray 2 will result.

lenses may appear to have a dull film or patina.

b. An alternative method is to compare the

illumination of the field of view of an instrument with the

same model number of series known to have' optical

elements that are uncoated. The instrument with coated

optics will have a much brighter field.

c. All fire-control instruments with coated optics

bear a decalcomania transfer with the following wording:

"This Instrument Has 'COATED OPTICS'. Clean Lenses

Carefully."

d. The magnesium fluoride coating is referred to as

hard coating. There are a few instruments in the field

with elements coated with what is referred to as soft

coating. The coating on these elements is not as

durable as the hard coating. A simple test will distinguish

a hard coating from a soft coating. With a soft rubber

Figure 4-34. Low-reflectance coating.

eraser, rub the coated element near the edge so as not

to impair the usefulness of the element. About 20

e. Since the wavelength is different for each

strokes will remove a soft coating, but hard coating will

different color of light, one color must be selected to

not be affected.

determine how thick the coating shall be. Green light,

4-16. Serviceability.

with a wavelength of 20 millionths of an inch, is the

a. Hard coating films on coated optics are tough

logical color to use since it is in the middle of the visible

and durable. They are insoluble in water, are not

spectrum. This color is in the brightest region and

affected by oil and alcohol, and salt water will not harm

contributes most to vision. The thickness of the coating,

them if cleaned off promptly. The coat will withstand

therefore, should be 1/4 of 20 millionths of an inch, or

temperature from -60 to +200ƒ F. They are specified to

equal to 5 millionths of an inch and result in increased

withstand a rubbing of a 3/8-inch pad of dry cotton,

transmission of green light and adjacent colors

exerting a force of 1 pound rubbed in any direction 50

(diminishing toward outer colors in spectrum). Reflection

times. However, due to the critical significance of the

of the colors at the extreme ends of the spectrum (red

thickness of the coating the effectiveness of the coating

and violet) is not eliminated completely. Therefore, light

may be completely destroyed by carelessness,

reflected from a coated optical element appears purplish,

ignorance, or rough treatment.

similar to a mixture of red and violet regardless of

b. Scratches tend to lower the quality of the lens.

coating material used. Thus presence of coating is

Wearing down of the film due to repeated cleaning is not

apparent to visual inspection. The common soap bubble

harmful to the element itself, but a reduction in thickness

or oil slick on water reflects iridescent colors because of

of the film much below one quarter of a wavelength of

the varying thickness of the film.

green light reduces its efficiency as a coated optical

f. Another useful application of magnesium fluoride

element. Partial or complete removal of the coating does

coatings is on front surface aluminized mirrors used in

not make the optical element useless but merely partly

optical instruments. In this case, a film thickness of one-

wholly takes away the benefit of the coating, leaving the

half wavelength causes reflected waves to reinforce

element as if it had not been coated in the first place. It

each other (fig 4-32).

is important that remnants of a partly deteriorated

Such coatings also may be applied to front surface

coating should not be removed, since even a partially

silvered mirrors. An aluminum or silver surface coated in

coated lens will be more effective than an uncoated one.

this manner is no longer soft and easily scratched, but

c. Coated optics slowly deteriorate under finger-

becomes harder and more durable and may be cleaned

prints, under prolonged action of atmospheric dust and

like other optical elements.

moisture, and salt water. Instruments containing coated

4-15. Identification

optics should be well sealed. Exceptional precautions

a. Whether or not an instrument is fitted with

must be taken to prevent sealing and cementing com-

coated optics can be detected readily by holding the

instrument at an angle to a source of light and observing

4-34

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |