|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-20-2

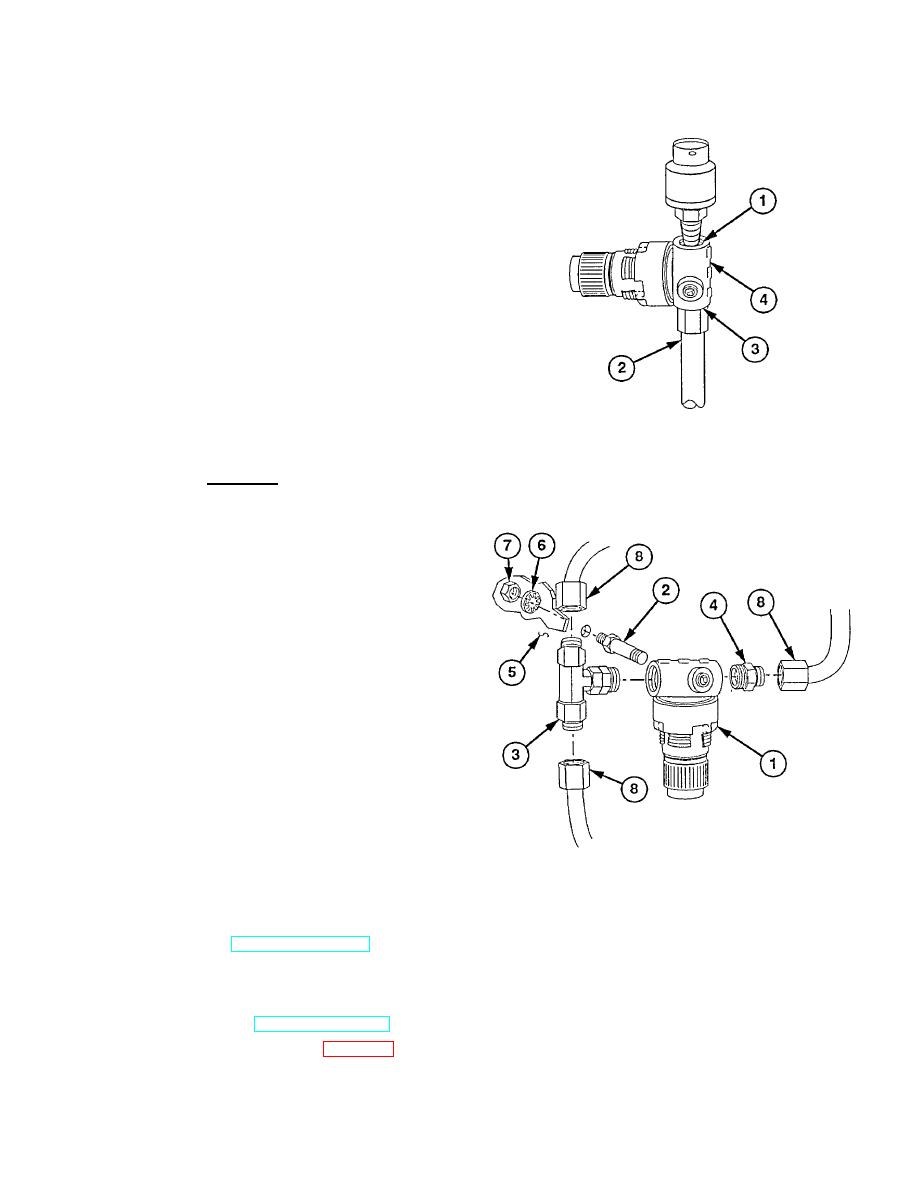

b. Adjustment

(1) Attach 0-1000 psi pressure transducer to

pressure regulator valve outlet port (1).

(2) Attach air supply hose (2) to pressure

regulator valve inlet port (3).

NOTE

Pressure regulator valve must be

adjusted to 70 psi (483 kPa).

(3) Adjust pressure regulator valve (4) to

proper air pressure using STE-ICE.

(4) Remove air supply hose (2) and pressure

transducer from pressure regulator valve (4).

c. Installation

(1) Install regulator valve (1) on stud (2).

WARNING

Pipe thread sealing compound can

burn easily, can give off harmful

vapors, and is harmful to skin and

clothing. To avoid injury or death,

keep away from open fire and use only

in well-ventilated areas. If pipe thread

sealing compound gets on skin or

clothing, wash immediately with soap

and water.

CAUTION

Use pipe thread sealing compound

sparingly only on pipe threads. Do not

apply compound at hose connections.

Damage to equipment may result.

(2) Coat threads of tee (3) and reducer (4)

with pipe thread sealing compound and

install on regulator valve (1).

(3) Install stud (2) on control console (5) with

new lockwasher (6) and nut (7).

(4) Connect hoses (8) to tee (3) and reducer (4).

d. Follow-On Maintenance

(1) Start engine (TM 9-2320-360-10).

(2) Build up air pressure to 120-125 psi (827-862 kPa).

(3) Check for leaks.

(4) Shut off engine (TM 9-2320-360-10).

(5) Install front console panel (para 17-8).

17-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |