|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-20-2

12-5. WHEEL AND TIRE REPAIR

This task covers:

Removal

Repair

Cleaning/Inspection

Follow-On Maintenance

Installation

INITIAL SETUP

Equipment Conditions

Tools and Special Tools (Cont)

Engine shut off (TM 9-2320-360-10).

Truck, Lift, Wheel (It em 56, Appendix F)

Parking brake on (TM 9-2320-360-10).

Wrench, Torque, 0-600 Lb-Ft (Item 74,

Wheels chocked.

Tools and Special Tools

Materials/Parts

Tool Kit, Genl Mech (Item 54, Appendix F)

Adhesive-Sealant (Item 5, Appendix C)

Blocks, Wooden (2) (Figure D-19, Appendix D)

Compound, Corrosion Preventive (Item 14.1,

Chock Block (TM 9-2320-360-10).

Jack, Hydraulic, 12-Ton (Item 17, Appendix F)

Lubricant, Tire and Rim (Item 17.1, Appendix C)

Jackstands, 7-Ton (Item 18, Appendix F)

Grommet (Item 43, Appendix G)

Repair Tool, Valve, Pneumatic Tire (Item 36,

Locknuts (4) (Item 46, Appendix G)

Packings, Preformed (2) (Item 136, Appendix G)

Socket Wrench Set, 3/4 In. Drive (Item 46,

Seal (Item 163, Appendix G)

Tire Irons (2) (Item 52, Appendix F)

Personnel Required

Two

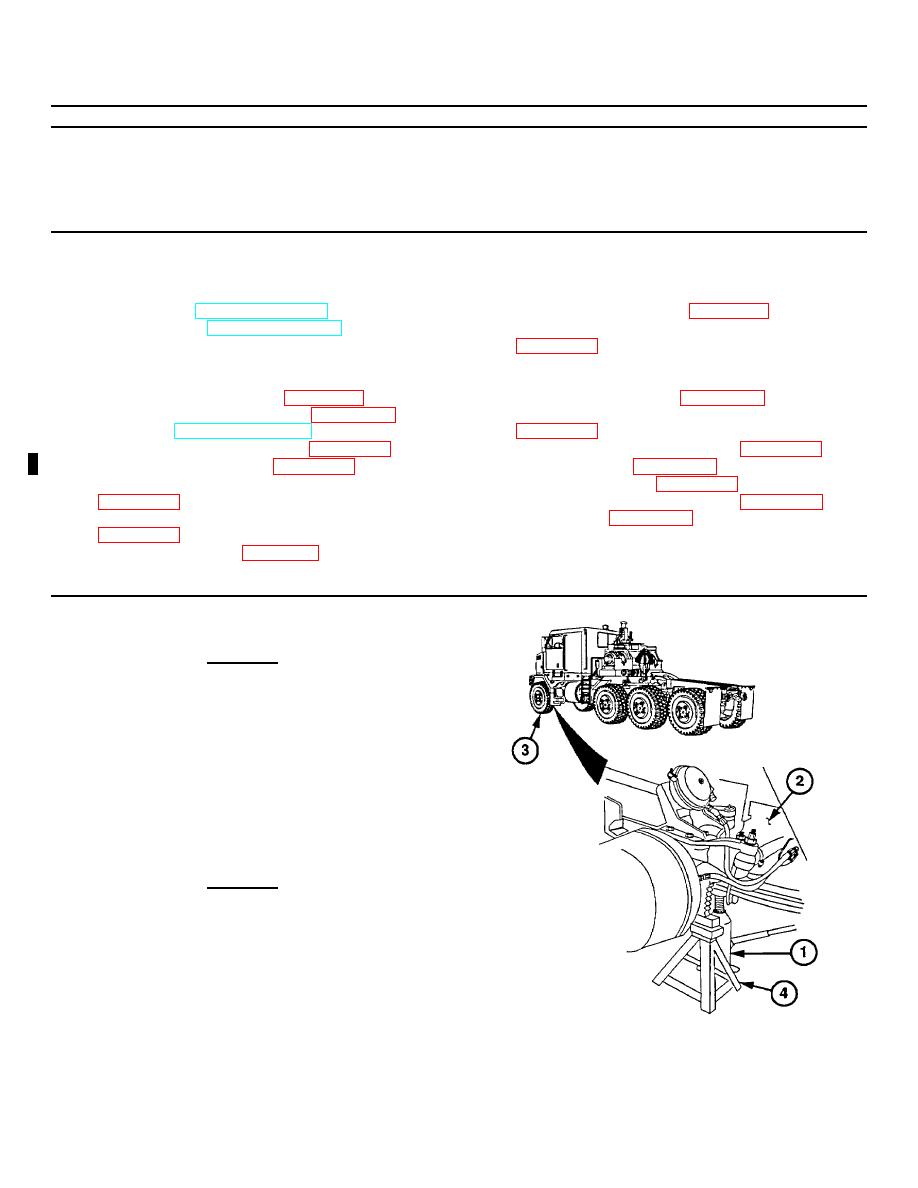

a. Jacking Procedure

WARNING

Hydraulic jack must be positioned on

flat surface. Placing Jack on unlevel

or soft surface may result in truck

falling and cause injury or death to

personnel.

(1) Position jack (1) under axle (2).

(2) Lift axle (2) until tire (3) is about 3 in. (8

cm) off ground.

WARNING

Jackstand must be positioned on flat

surface.

Placing jackstand on

unlevel or soft surface may result In

truck falling and cause injury or

death to personnel.

(3) Place jackstand (4) under axle (2) not

more than 10 in. (25 cm) from tire (3).

TIRE REMOVED FOR CLARITY

12-18 Change 3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |