|

|||

|

|

|||

|

Page Title:

PROPELLER SHAFT AND UNIVERSAL JOINT REPAIR |

|

||

| ||||||||||

|

|

TM 9-2320-360-20-2

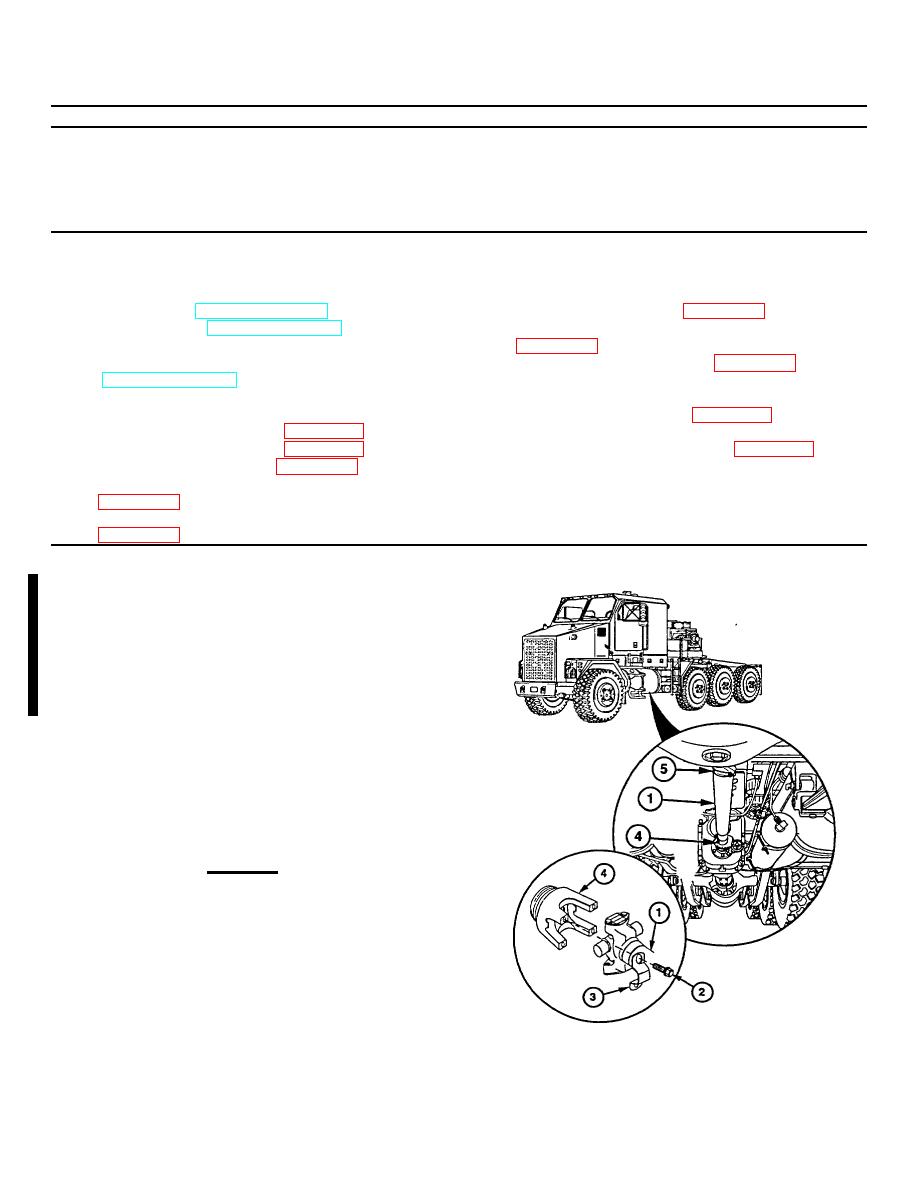

10-2. PROPELLER SHAFT AND UNIVERSAL JOINT REPAIR

This task covers:

a. Removal

d. Assembly

b. Disassembly

e. Installation

c. Cleaning/Inspection

f. Follow-On Maintenance

INITIAL SETUP

Equipment Conditions

Materials/Parts

Engine shut off (TM 9-2320-360-10).

Adhesive-Sealant (It em 6, Appendix C)

Parking brake on (TM 9-2320-360-10).

Grease, Automotive and Artillery (Item 17,

Wheels chocked.

Transfer case shift lever set to NEUTRAL

Solvent Dry Cleaning (Item 31, Appendix C)

(TM 9-2320-360-10).

Lockstraps, Transmission to Transfer Case,

Transfer Case to No. 2 Axle, and No. 2 Axle to

No. 3 Axle (12) (Item 85, Appendix G)

Tools and Special Tools

Tool Kit, Genl Mech (Item 54, Appendix F)

Lockstraps, Transfer Case to No. 1 Axle and No. 3

Compressor Unit, Air (Item 3, Appendix F)

Axle to No. 4 Axle (8) (Item 86, Appendix G)

Goggles, Industrial (Item 14, Appendix F)

Socket Wrench Set, 3/8 In. Drive (Item 45,

Personnel Required

Two

Wrench, Torque 0-175 Lb-Ft (Item 73,

CAUTION

Propshaft parts must not be rotated

from their original position during

reassembly. An indexing line should

be drawn down entire length of all

assemblies prior to removal. Failure

to comply may result in driveline

vibration and damage to equipment.

NOTE

These procedures are used for all

propeller shafts. Propeller shafts are

all removed, disassembled, cleaned

and inspected, assembled, and

installed the same way.

a. Removal

WARNING

Support

propeller

shaft

during

removal. Injury to personnel may

result if propeller shaft falls.

(1) Support propeller shaft (1) with lifting strap

and aid of assistant.

(2) Remove four capscrews (2) and two

bearing straps (3) from yoke (4).

(3) Repeat step (2) for yoke (5).

10-2 Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |