|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-20-2

7-34.1. DDEC III OIL PRESSURE SENSOR REPLACEMENT (CONT)

b. Installation

WARNING

Pipe thread sealing compound can

bum easily, can give off harmful

vapors, and is harmful to skin and

clothing. To avoid injury or death,

keep away from open fire and use In

well-ventilated area. If pipe thread

sealing compound gets on skin or

clothing, wash immediately with soap

and water.

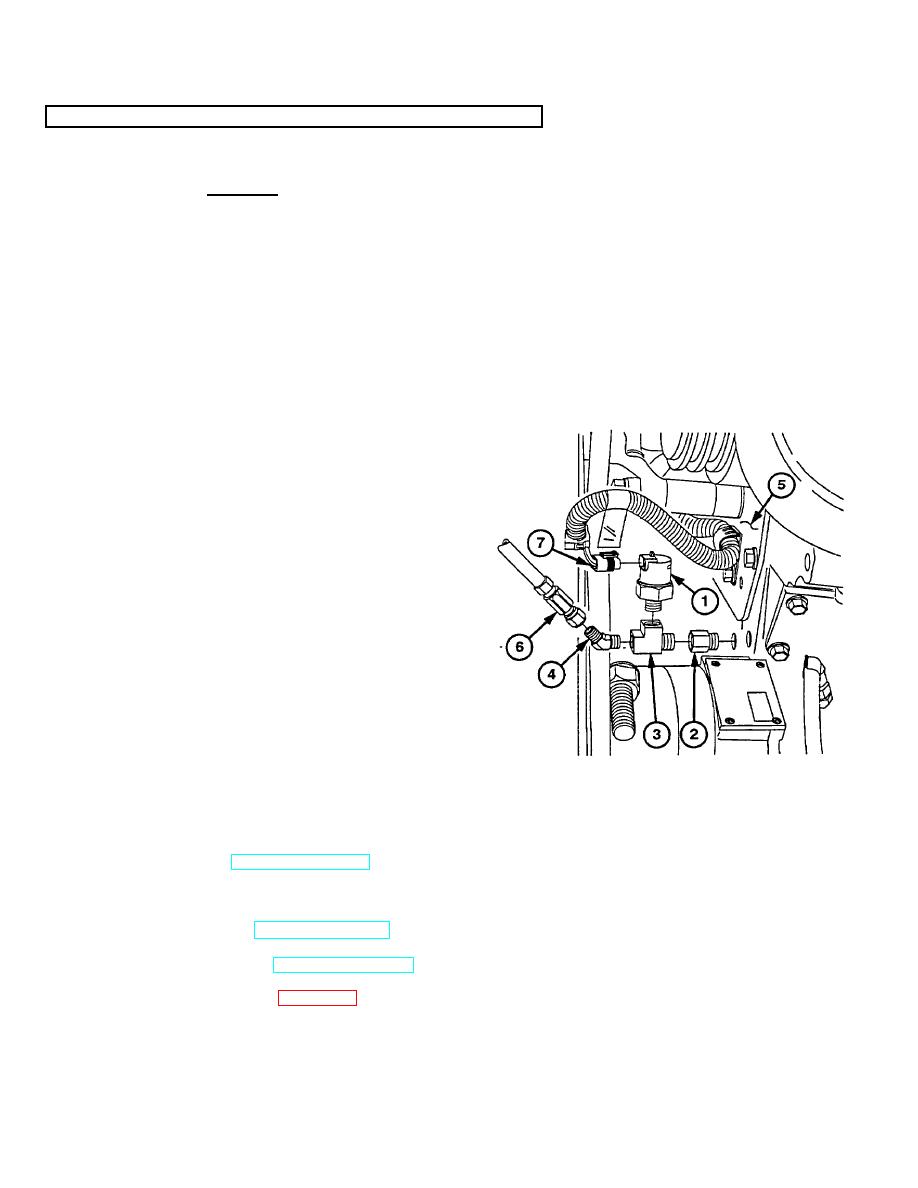

(1) Coat all but first two threads of oil

pressure sensor (1) with pipe thread

sealing compound.

NOTE

Do steps (2) thru (5) only if elbow and

fitting were removed.

(2) Coat threads of fitting (2), tee (3), and

elbow (4) with pipe thread sealing

compound.

(3) Install fitting (2) in engine (5).

(4) Install tee (3) in fitting (2).

(5) Install elbow (4) on tee (3).

(6) Install oil pressure sensor (1) on tee (3).

(7) Install fan clutch oil line (6) on elbow (4).

(8) install electrical connector

(7)

on

oil

pressure sensor (1).

c. Follow-On Maintenance

(1) Start engine (TM 9-2320-360-10).

(2) Check for leaks around sensor.

(3) Shut off engine (TM 9-2320-360-10).

(4) Close engine hood (TM 9-2320-360-10).

(5) Install inner fender (para 16-34).

(6) Clear inactive codes (Appx H).

7-96.2 Change 3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |