|

|||

|

|

|||

|

Page Title:

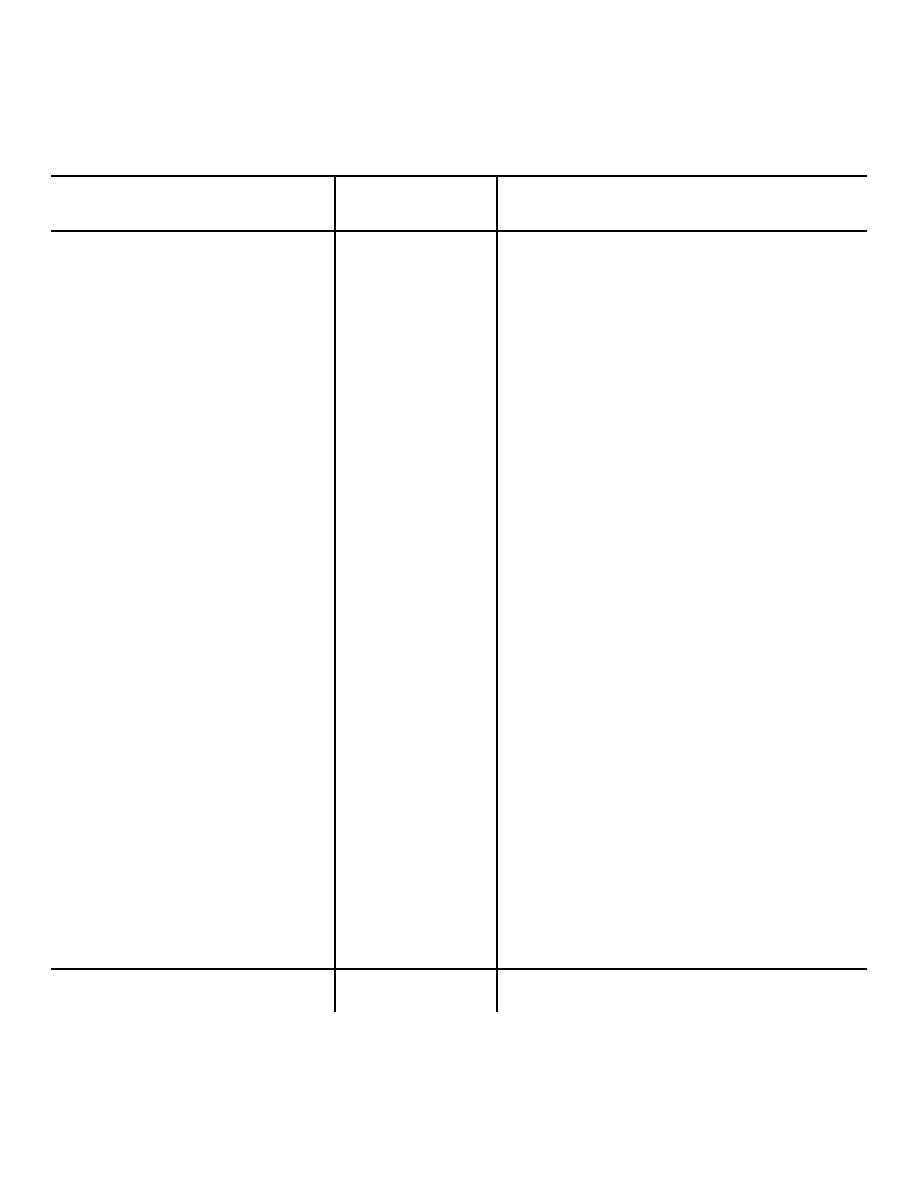

CALIBRATION CHART (Continued) |

|

||

| ||||||||||

|

|

TM 9-2320-269-34-1

FUEL INJECTION PUMP - CONTINUED

ADJUSTMENT - CONTINUED

CALIBRATION CHART (Continued)

Check

RPM

Specifications

6. Continued

c) Balance (Max Spread)

1500

+ 180 inch (3mm)

cu inch/stroke (cu mm/

-300 inch (5mm)

From Avg

stroke)

7. Torque Compensation

End of Torque Compensa-

tion; Rack Position

1)

950

----------------------------

2)

600

Same as 6 a

8. Enter Excess Fuel:

100

Rack position should be 0.7480 - 0.8268 inch

Rack Position

(19 - 21 mm)

9. Exit Excess Fuel;

250

+ 0.0039 inch (+ 0.1 mm)

Rack Position

-0.0000 inch (-0.0 mm) from 7d.2

10. Transitions; Ave. Delivery

cu inch/stroke (cu mm/stroke)

a) Cylinders 1-4-6-7

300

60 - 90 inch (1 - 15 mm)

b) Cylinders 2-3-5-8

300

198 - 240 inch (33 - 40 mm)

11. LO-Idle Rack Position

300

0.2362 inch (Ref) (6.0 mm)

12. Start Fuel Quantity:

a) Cylinders 1-4-6-7

100

0.0000 inch (0.0 mm)

b) Cylinders 2-3-5-8

100

8100 - 6720 inch (135 - 112 mm)

cu Inch/stroke (cu mm/

stroke)

13. Fuel Shutoff, Rack Position

0

0.0394 inch (1.0 mm) maximum

14. Pump Drive Tang Adjustment

0

Drive tangs must be horizontal with punch marks

at Lift-To-Port Closure of

facing transfer pump

#1 Plunger

2-310

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |