|

|||

|

|

|||

|

Page Title:

INSPECTIONIREPLACEMENT/REPAIR - CONTINUED |

|

||

| ||||||||||

|

|

TM 9-2320-269-34-1

PISTONS AND CONNECTING RODS - CONTINUED

ACTION

LOCATION

ITEM

REMARKS

INSPECTION/REPLACEMENT/REPAIR - CONTINUED

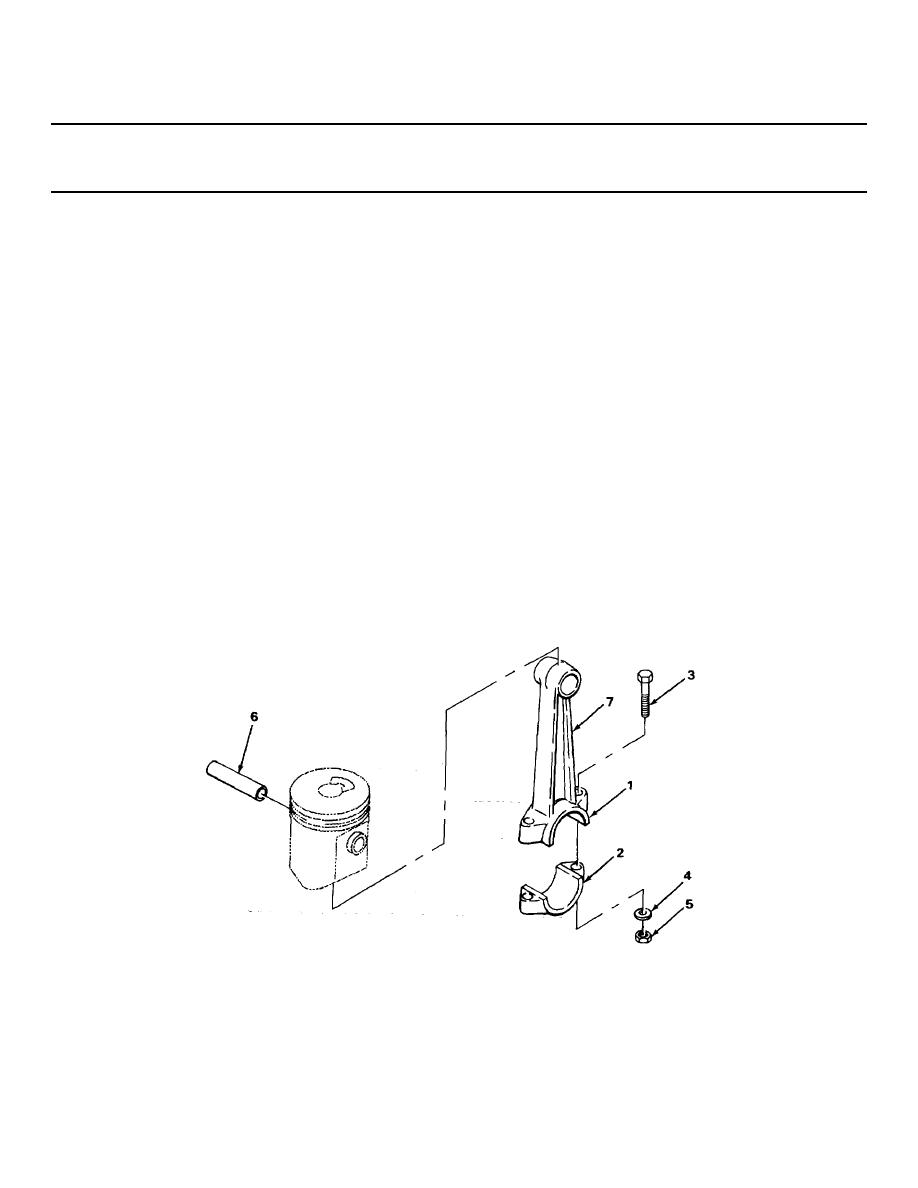

39.

Continued

e.

If connecting rod bearing bore does

not pass the above inspections, con-

necting rod must be replaced.

40.

Connecting rod

Two nuts (5), Using 11116-inch socket and ratchet handle

(1) and bearing

washers (4), and

with 112-inch drive, unscrew and

take out.

cap (2)

screws (3)

41.

Piston pin (6)

a.

Look for cracks, scratches, and

nicks.

b.

Look for chips and gouges in snapring

grooves.

c.

If pin (6) is damaged, replace it.

42.

Piston pin bushing

a.

Check pin (6) for scratches, wear, and

(7) and piston

out of round.

pin (6)

b.

Insert pin (6) through bushing (7) and

check for fit.

c.

If bushing (7) is damaged and needs re-

placing, using arbor press, press out.

d.

Get rid of bushing (7).

e.

Position connecting rod (1) in press,

large chamfer side of bushing bore,

facing down.

TA238003

2-153

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |