|

|||

|

|

|||

|

Page Title:

INSPECTION/REPLACEMENT/REPAIR - CONTINUED |

|

||

| ||||||||||

|

|

TM 9-2320-269-34-1

PISTONS AND CONNECTING RODS - CONTINUED

ACTION

LOCATION

ITEM

REMARKS

INSPECTION/REPLACEMENT/REPAIR - CONTINUED

34.

Continued

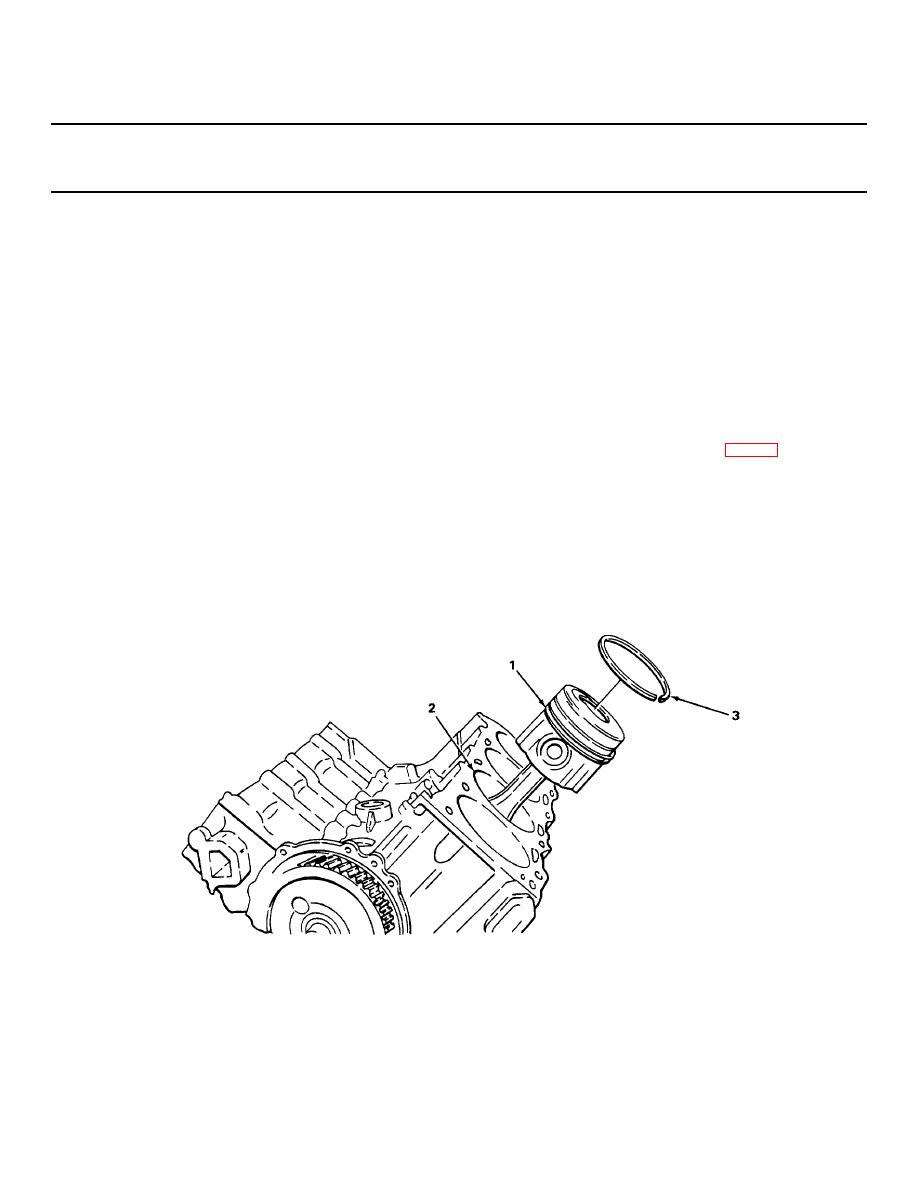

New piston c.

Take ring (3) out of bore (2).

rings (3)

d. If ring gap is too small, try another

size.

e.

Fit and check again each ring (3) in

bore In which it is used, and mark ring

accordingly.

f.

Check ring-to-groove clearance by in-

serting edge of ring (3) into proper

ring groove of piston (1).

g.

Using thickness gage, check clear-

ance between top or bottom of ring

(3) and side of groove.

See Repair and Replacement

Standards (page 1-6) for ring-to-

groove limits.

h.

Take ring (3) out of ring groove.

35.

Piston (1)

a.

Check top keystone-type compression

ring groove for wear by Inserting per-

fect circle piston ring gage, number

one (1/8 x 15 degree), into groove.

b.

If one or both shoulders of the gage

touch the side of the piston, piston

must be replaced.

TA238002

2-151

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |