|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-269-34-1

CYLINDER HEADS - CONTINUED

ACTION

LOCATION

ITEM

REMARKS

REPAIR - CONTINUED

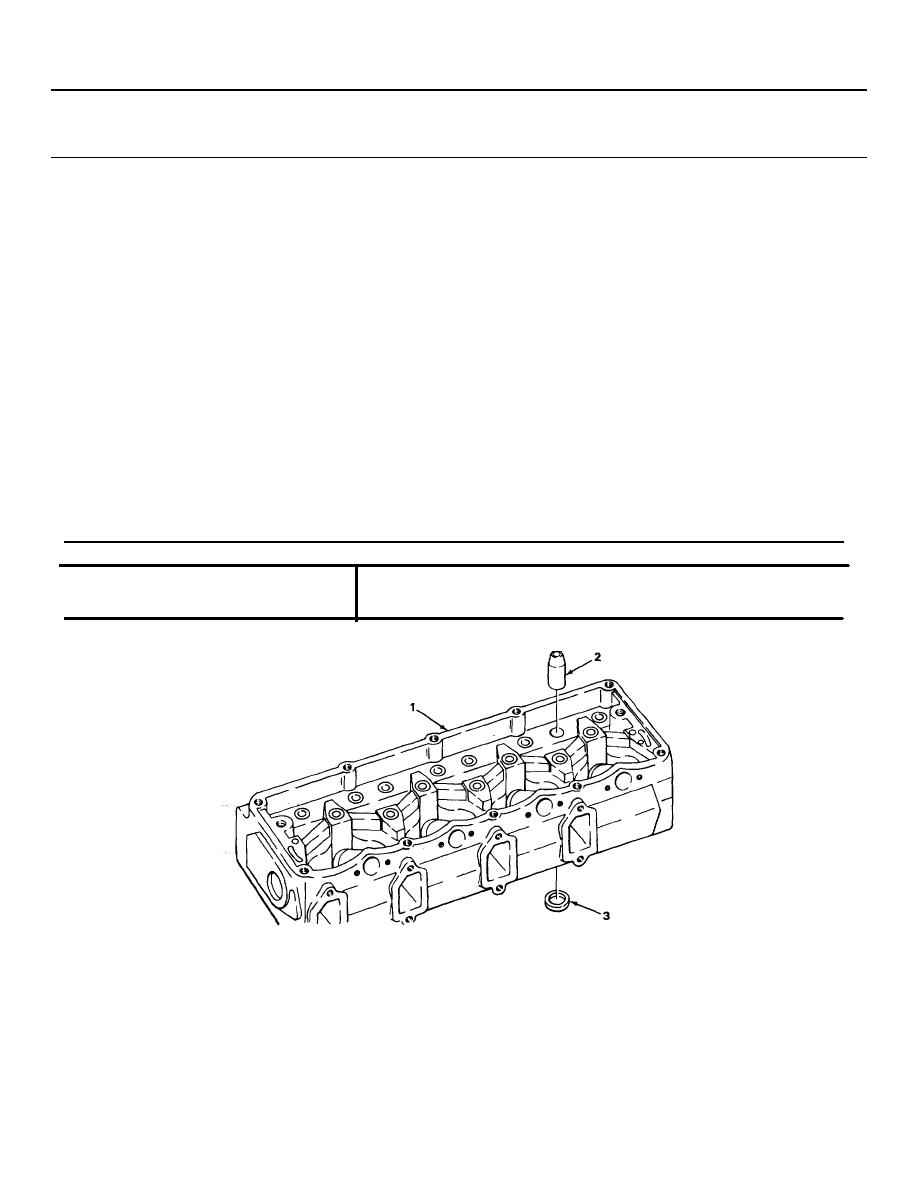

22.

Continued

f.

Chill insert (3) thoroughly with dry

ice.

g.

Position insert (3) on installer tool

and using installer tool and 3-lb

ball-peen hammer, drive insert (3) into

head (1).

NOTE

Do not peen around injection nozzle area or on intake valve insert.

h.

Using 1/4-inch blunt end drive-pin

punch and 3-lb ball-peen hammer,

peen head (1) metal over outer edge

of insert (3).

i.

Using valve seat grinder, reface

insert (3).

Use chart below for specific angle

and seat width. During grinding

operation, take off the minimum

amount of material necessary to t

up the insert.

INTAKE AND EXHAUST VALVE SEAT INSERTS

FACE ANGLE

45 degrees

SEAT ANGLE

45 degrees

SEAT WIDTH

0.080 - 0.090 inch 2.03 - 2.29 millimeter

TA237974

2-109

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |