|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-269-34-1

REPAIR - CONTINUED

Painting:

Refer to TM 43-0139.

Soldering: Solder connections must be bright and clean before soldering. Take off dirt and grease with cleaning

compound MIL-C-81302 and small, stiff-fiber brush. Solder must be nonacid type (SN60 per QQ-S-571). Rosin flux, O-F-

506, Type 1, Form A, can be used. All wires, parts, and solder Iron must be pretinned for good connection and maximum

transfer of heat. Clean all solder joints with acid swabbing brush and cleaning compound after soldering to get a bright

and clean surface.

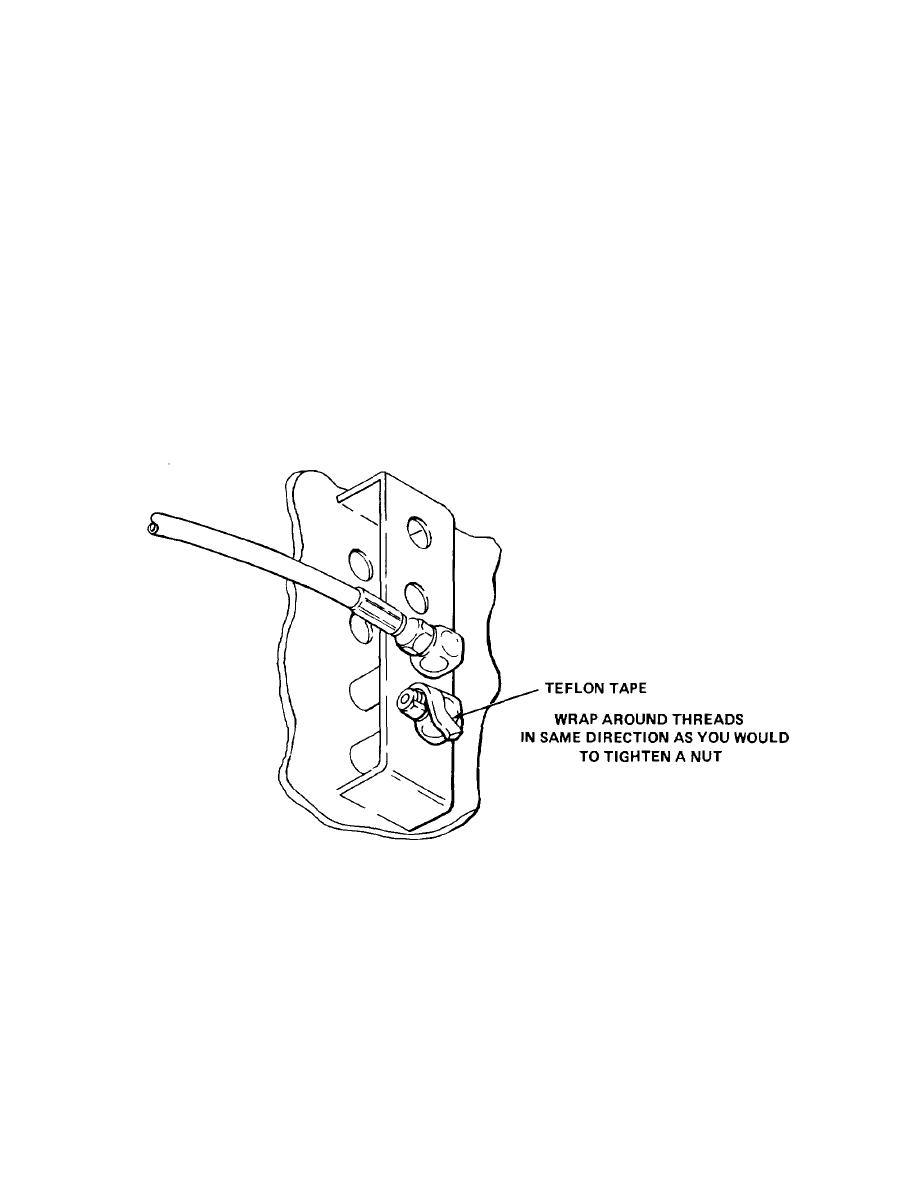

Teflon Tape: Be sure threads are clean and dry. Start tape one or two threads from small or leading edge of plug or

screw, Joining tape together with an overlap about 1/8-inch (3.18 millimeters). For coarse threads, tape may be wrapped

around two or three times.

Wrap tape tightly in the same direction as you would turn a nut. Press tape into the threads without cutting or tearing the

tape.

Hand tighten and hand torque the plug or screw. DO NOT go over specified torque. DO NOT use power tools.

FLUID DISPOSAL

Get rid of fluids in accordance with your unit's Standard Operating Procedures (SOP).

2-50

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |