|

|||

|

|

|||

|

Page Title:

REPAIR AND REPLACEMENT STANDARDS - CONTINUED |

|

||

| ||||||||||

|

|

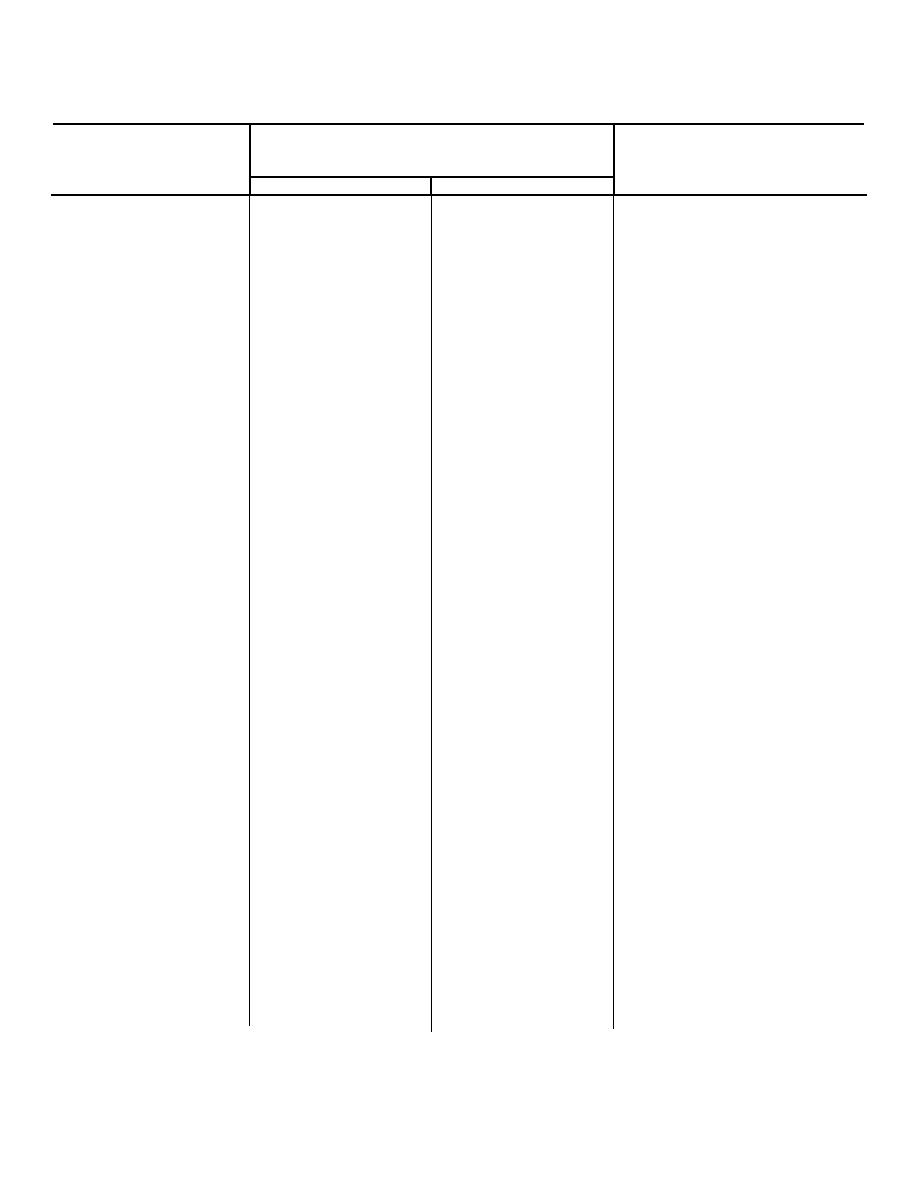

TM 9-2320-269-34-1

REPAIR AND REPLACEMENT STANDARDS - CONTINUED

COMPONENT

MANUFACTURER'S DIMENSIONS

MAXIMUM ALLOWABLE

POINTS OF

AND TOLERANCES IN INCHES

WEAR AND CLEARANCE

MEASUREMENT

(MILLIMETERS)

IN INCHES (MILLIMETERS)

MINIMUM

MAXIMUM

PISTON PINS

Length

3.240 (82.30)

3.250 (82.55)

Diameter

1.4998 (38.095)

1.5000 (38.1)

Pin fit at 70F

(21 C):

Clearance in rod

0.0009 (0.023)

0.0013 (0.033)

Clearance in piston

0.0002 (0.005)

0.0006 (0.015)

loose

PISTON RINGS

Diameter

4.5(114.3)

Compression rings

Size (top)

Tapered

Size (second)

3/32 (2.83)

Fit in groove (top)

Tapered

Fit in groove (second)

0.0035 (0.089)

0.0055 (0.140)

Gap

0.013 (0.33)

0.023 (0.58)

OIL CONTROL RINGS

Size

0.188 (4.763)

Fit in groove

0.0015 (0.038)

0.003 (0.076)

Gap

0.013 (0.33)

0.028 (0.71)

INTAKE VALVES

Valve lift

0.455 (11.56)

Stem diameter

0.3725 (9.461)

0.3730 (9.474)

Clearance in guide

0.0008 (0.020)

0.0023 (0.054)

Face angle

45 degrees

Seat angle

45 degrees

Seat width

0.080 (2.03)

0.090 (2.29)

Maximum seat runout

0.002 (0.05)

Maximum face runout

0.002 (0.05)

Seat insert and

counterbore data:

Standard

Insert od

2.204 (55.98)

2.207 (56.06)

Counterbore diameter

2.200 (55.88)

2.204 (55.98)

0.002 (0.05) oversize

Insert od

2.206 (56.03)

2.207 (56.06)

Counterbore diameter

2.202 (55.93)

2.204 (55.98)

0.030 (0.762) oversize

Insert od

2.234 (56.74)

2.235 (56.77)

Counterbore diameter

2.230 (56.64)

2.232 (56.69)

1-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |