|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-1375-213-12-1

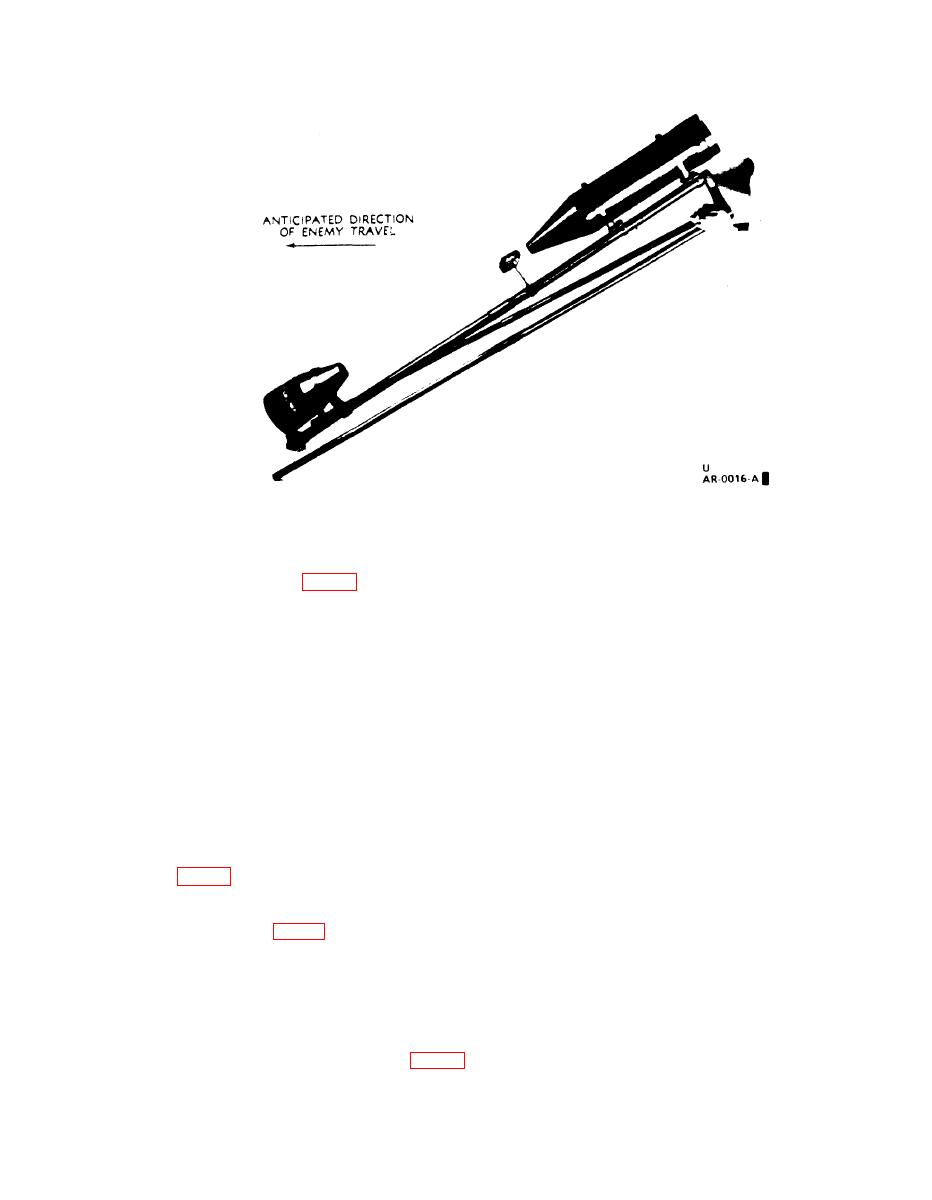

Figure 2-5.

Erecting tripod.

(6) Step back about 10 feet (3.0 meters) and

the launch leg is pointed in the direction

check alignment of components on launch leg. If

of the enemy travel (fig. 2-6).

components are not aligned, attempt improve-

c. The rocket motor may be assembled to the

ment by using the hex socket head wrench which

warhead prior to erecting the tripod by following

is taped to one of the legs to change the position

the procedures in f below, prior to proceeding to

of the upper bracket holding the shaped charge

d.

to the launch leg.

d. Using base of launch leg as a pivot, and stand-

2-5. Preparing Field Firing Lead

ing at rear of warhead, raise tripod and pivot sup-

port legs outward as far as possible.

NOTE

e. Keeping support legs fully extended, tilt tri-

Make sure electrical wire splices are se-

pod backward until support legs meet ground. To

curely twisted together. Use at least two

avoid accidental toppling of tripod, assure that

inches of bared conductor from each wire

restraining wires are taut and legs are firmly po-

end being spliced. Insulate each conduc-

sitioned on ground.

tor splice with tape to prevent shorting.

f. Mount each rocket motor as follows:

a. Lay field firing lead (electrical

(1) Unlatch peripheral clamp holding protec-

power cable or type WD-1/TT telephone

tive disk on warhead by pulling on the nylon cord

cable) from kit (s) to firing location.

loop (A, fig. 2-7).

To prevent accidental toppling of the

(2) Remove protective disk and put it in ship-

M180 kit due to pulling or tripping on

ping container; leave clamp on warhead.

the firing lead, wind field lead around

(3) Align ring (B, fig. 2-7) of rocket motor with

a stake or other object secured to the

mating groove on rear of warhead flange. Insert

ground.

ring into groove and insure that clamp is over both

rocket and warhead flanges.

b. Short circuit firing lead Conductors at firing

(4) Rotate rocket motor so that continuity plug

(blasting machine) location.

and yellow-tagged safety plug are on top.

c. At kit location, check firing lead with galva-

nometer or Blasting Cap Test Set M51. If a gal-

(5) Hold peripheral clamp in place and snap

vanometer is being used, about 23 ohms should he

shut to secure rocket motor to warhead (fig. 2-8).

2-7

Change 3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |