|

|||

|

|

|||

|

Page Title:

Chapter 5 ORGANIZATIONAL MAINTENANCE INSTRUCTIONS |

|

||

| ||||||||||

|

|

CHAPTER 5

ORGANIZATIONAL MAINTENANCE INSTRUCTIONS

TOOLS AND EQUIPMENT

Section I.

No special tools or equipment are required by organizational maintenance.

Section II.

REPAINTING AND REFINISHING INSTRUCTIONS

5-1. General

lightly sanding them with fine sandpaper. Brush two

thin coats of paint (color 26492 per Federal Standard

Metal surfaces of the processor and receiver are

595) on the bare metal to protect it from further

painted with a very durable undercoat and finish

corrosion. Refer to applicable cleaning and refinish-

paint. Under normal conditions the paint will

ing practices specified in TB 746-10.

permanently remain on the surfaces and will require

a. For processor and receiver enclosures and

no retouching or repainting. However, the paint may

covers use grey paint.

become chipped or worn away from accidental

b. When touchup painting in the vicinity of the

causes, such as being bumped by a sharp object, or

perforated holes in the receiver cover, remove the

being subjected to abrasive damage of various types.

cover (prior to painting) by removing two screws (fig.

If such damage occurs, the damaged area should be

retouched, or repainted, both for appearance and to

c. For interconnecting conduit use aluminum

protect the steel case from corrosion.

paint.

CAUTION

5-2 Touchup Painting Instructions

Do not use excessive paint to the point where

Remove rust and corrosion from metal surfaces by

the perforated holes are filled in.

Section Ill. LUBRICATION INSTRUCTIONS

No lubrication instructions are requird by organizational maintenance in the performance of their duties.

Section IV.

PREVENTIVE MAINTENANCE CHECKS AND SERVICES

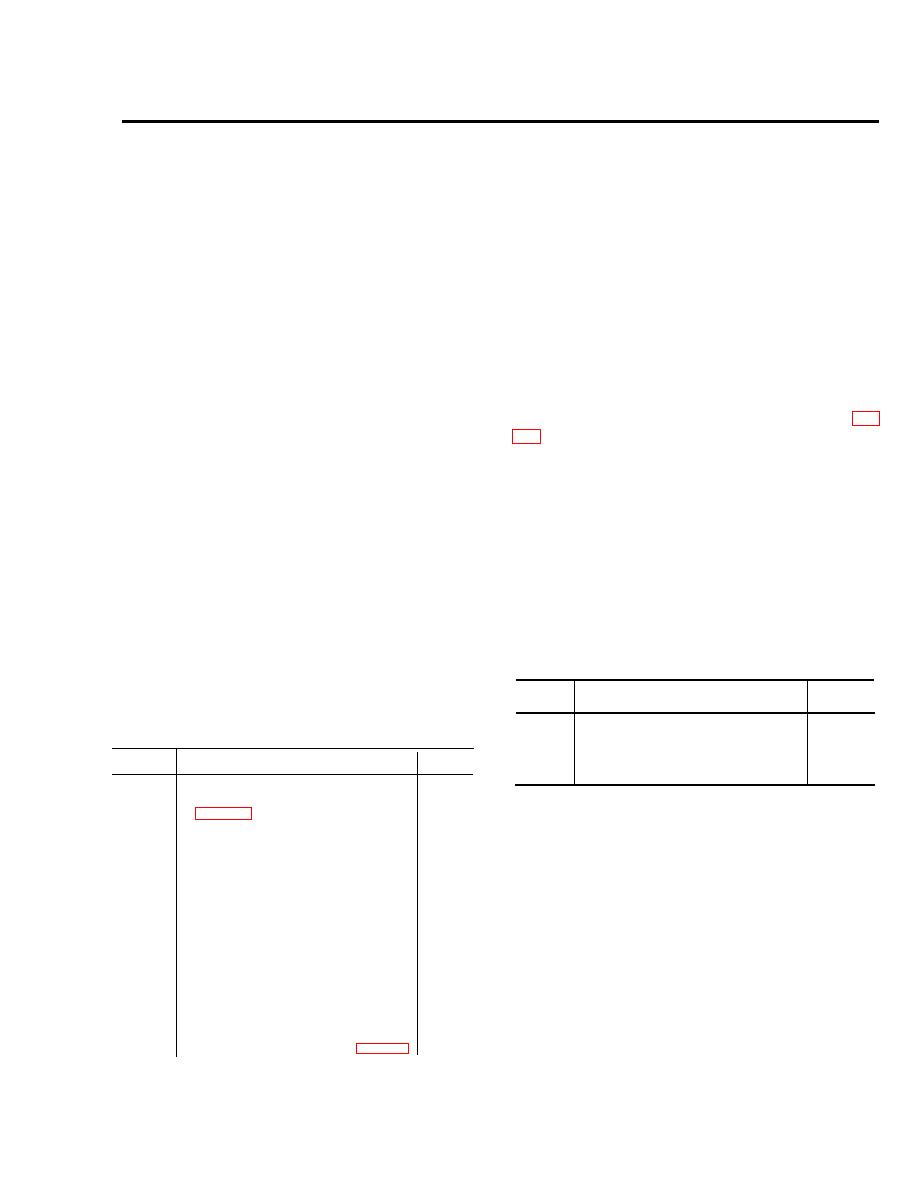

5-3. Organizational Monthly Preventive

Sequence

Items to be Inspected

Work Time

Maintenance Checks and Services.

Procedure

No.

(M/H)

Table 5-1. Organizational Preventive

6

METAL SURFACES

Maintenance Checks and Services

Inspect exposed metal surfaces for

rust and corrosion. Clean and

Sequence

Item. to be Inspected

Work Time

No.

Procedure

(M/H)

touchup paint as required.

1

See that the equipment is complete

5-4. Cleaning

2

EXTERIOR

Inspect the exterior of the equipment. The exterior

Inspect unit exterior for properly

secured enclosure covers and

surfaces should be free of dust, dirt, grease and

enclosure damage.

fungus.

3

a. Remove dust and loose dirt with a clean, soft

Inspect interconnections and conduit

cloth.

for damage or tampering.

CAUTION

4

SURVEILLANCE OBSTRUCTIONS

Do not use Trichloroethane or any other

Inspect receivers for clear line of sight

for surveillance area No obstructions,

hydrocarbon cleaning agents. Use only soap

stacked material or objects hung in

and water for cleaning purposes.

front of the receivers.

a. Remove grease, fungus, and ground-in dirt

5

SURVEILLANCE ADEQUACY

from the case using a cloth dampened (not wet) with

Perform a simulated forced penetra-

soap and water.

tion test of the protected area (para 2-8)

5-1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |