|

|||

|

|

|||

|

Page Title:

Section V. DIRECT SUPPORT TESTING PROCEDURES |

|

||

| ||||||||||

|

|

components within junction box housing.

(1) Components for cleanliness.

c. Repair Precautions. Use standard maintenance

(2) Painted surfaces for deterioration or

practices and observe the following precautions:

scratches.

(3) Screws for damage or corroded threads.

(1) Use exact replacements parts if possible; a

(4) Nuts and screw holes to insure they are not

part with the electrical value or function but

stripped.

different physical size may cause trouble.

(5) Components for breaks. chips, or cracks.

(2) Soldering irons of less than 50 watts should be

(6) Moving parts for wear.

used to solder this equipment. Overheating of some

(7) Electrical wiring for fraying or other damage.

parts may cause damage.

(8) All attaching and mounting hardware for

tightness.

5-10. Disassembly and Assembly

b. Cleaning. Use a mild solution of warm water and

Refer to figure C-1 to disassemble and assemble the

liquid soap to clean housing and cover parts. After

grid wire sensor for removal and installation of

cleaning rinse parts with cold water to remove any

tamper switches. Component locations, attaching

soap solution and dry thoroughly. Use a soft

parts, and installation kit components are illustrated

camel's-hair brush or vacuum cleaner with suitable

in figures C-1 and C-2.

attachment to remove accumulated dust from

Section V. DIRECT SUPPORT TESTING PROCEDURES

5-11. General

5-12. Performance Standards

This section contains a performance standard test

a. Test Equipment ATS 352B VOM or equivalent

procedure for use by direct support maintenance

voltohmmeter is required to perform the perfor-

personnel to determine whether the performance of

mance standards.

the repaired grid wire junction box is satisfactory for

b. Procedures. Refer to table 5-1.

installation.

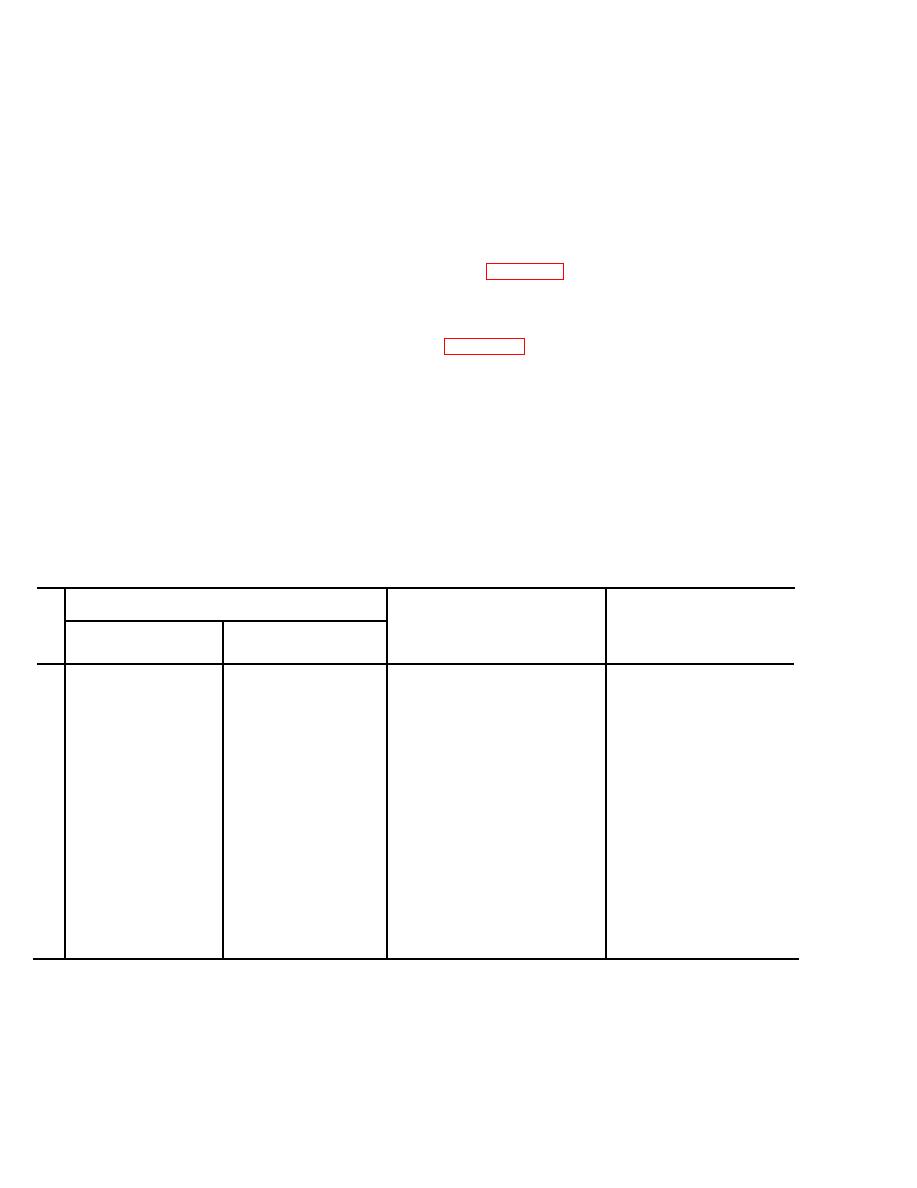

Control setting

Test

Performance

Step

procedure

standard

Test

Equipment

no.

under test

equipment

a. None

a. Remove junction box cover.

1

N/A

N/A

b. None

through conduit enrty port

and connect between TB-5

and -6.

2

a. Meter should indicate 2 ohms

Pry-off switch

a. Place junction box on work

VOM. TS352B:

or less.

bench wit with mounting

RX1

surface down.

(zero meter).

a. Meter should indicates more than

3

a. Raise junction box approx-

Pry-off switch.

VOM. TS352B:

100,000 ohms.

imately 3/16 inch.

RX1K

(zero meter).

a. Meter should indicate 2 ohm or

a. Place cover on junction box

Tamper switch.

4

VOM, TS352B:

less.

without retaining screws.

RX1

a. Meter should indicate more than

a. Raise junction box cover

5

Tamper switch.

VOM. TS352B:

100,000 ohms.

3/16 inch.

RX1K

a. None.

6

N/A

N/A

b. None

b. Install cover and cover

screws.

5-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |