|

|||

|

|

|||

|

Page Title:

Section V. DIRECT SUPPORT (INTERMEDIATE) TEST PROCEDURE |

|

||

| ||||||||||

|

|

TM 5-6350-262-14/1

NAVELEX 0967-LP-466-9012

TO 31S9-4-36-1 Chg 2

Section V. DIRECT SUPPORT (INTERMEDIATE) TEST PROCEDURE

7-12. Performance Test Procedures

7-11. General

Chart 7-2 establishes the minimum performance

These testing procedures are prepared for use by

standards required for the determination of the

electronic field maintenance shops and electronic

serviceability of assemblies maintained at the Direct

service organizations responsible for Direct Support

Support (intermediate) category of maintenance.

(intermediate) maintenance of electronic equipment.

These procedures set forth the specific requirements

that repaired electronic equipment must meet before it

NOTE

is returned to the using organizations.

When

performing

the

procedures

disconnect all test equipment at the

completion of each step with the

exception of the power supply. Set the

power supply to off when connecting and

disconnecting test setups.

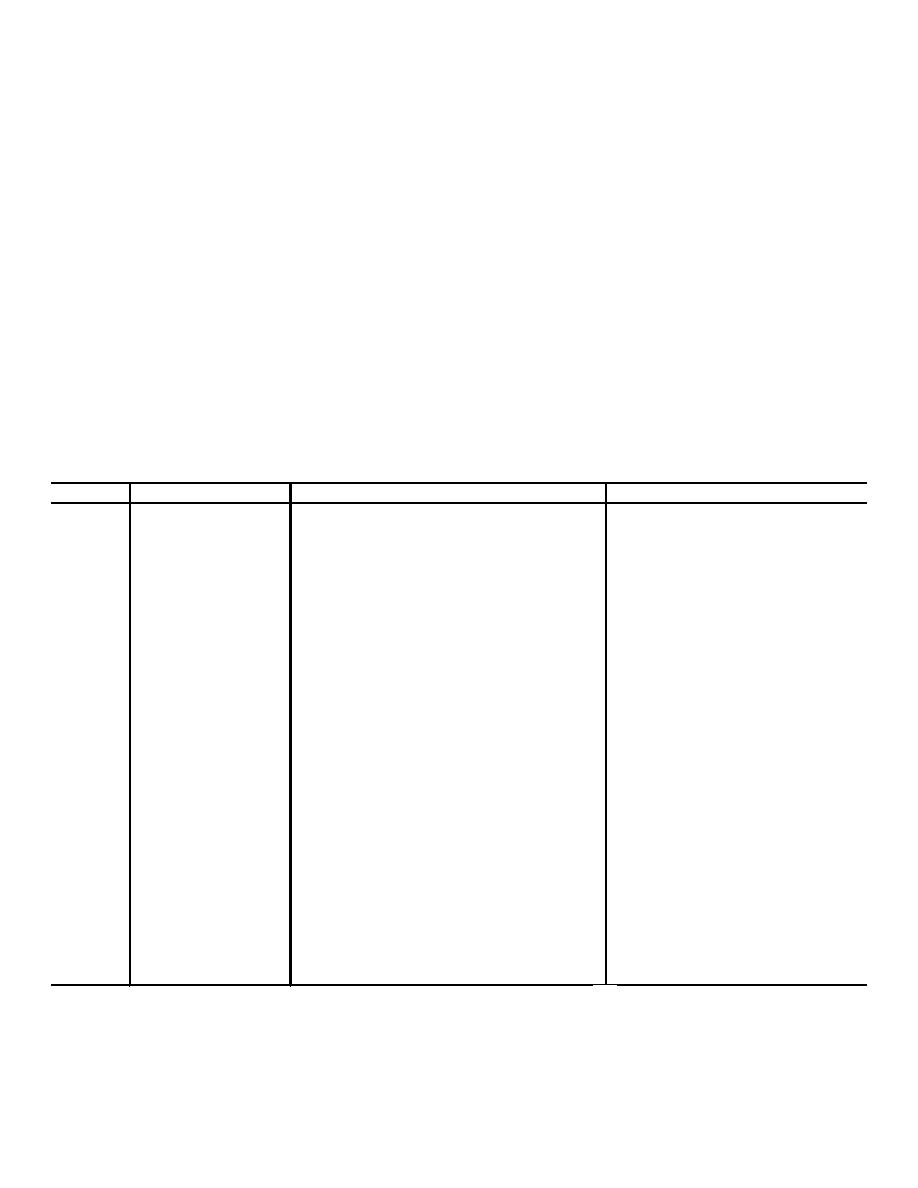

CHART 7-2. Processor/Transceiver Ultrasonic Motion Signal Performance Test Procedures.

Step #

Test Equipment

Test Procedure

Performance Standard

NOTE

Interconnect the transceiver and the pro-

cessor. Set up the equipment in a large

room (at least 20 x 40 feet) with the

transceiver pointed along the maximum

dimension of the room. Set the RANGE

control to 10.

1.

Power Supply

Connect the positive lead to terminal 7 of TB1

Set for 20 Vdc.

and negative to terminal 8 of TB1 in the

processor.

2.

Multimeter as a

Connect between terminals 1 and 2 of TB1 in

Multimeter shall read 110 ohms for a

continuity check

the processor. Walk test the system.

no alarm condition. Multimeter shall

Starting at a distance greater than 40 feet

read greater than 100K for an alarm

and walk toward the transceiver along the

condition.

Boresight line. A speed of approximately

System shall alarm for target motion

1 foot per second is sufficient. Observe

at 355 feet along boresight line.

the multimeter and note the target

location at which time the system alarms.

3.

Multimeter

Connect as continuity measurement between

a The tamper switch shall open

terminals 5 and 6 of TB1 for the transceiver.

(infinity indication) with no less than

1/8 inch or more than inch cover

displacement.

b. Pull the tamper switch plunger out

and verify that continuity is restored

(near zero resistance).

c. Replace cover and verify that

continuity is again obtained (near

zero resistance).

4.

Multimeter

Repeat 3 above for the processor.

Same as 3 above.

Change 2 7-8.1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |