|

|||

|

|

|||

|

Page Title:

Table 4-1. Organizational Preventive Maintenance Checks and Services |

|

||

| ||||||||||

|

|

TM 5-5420-205-14

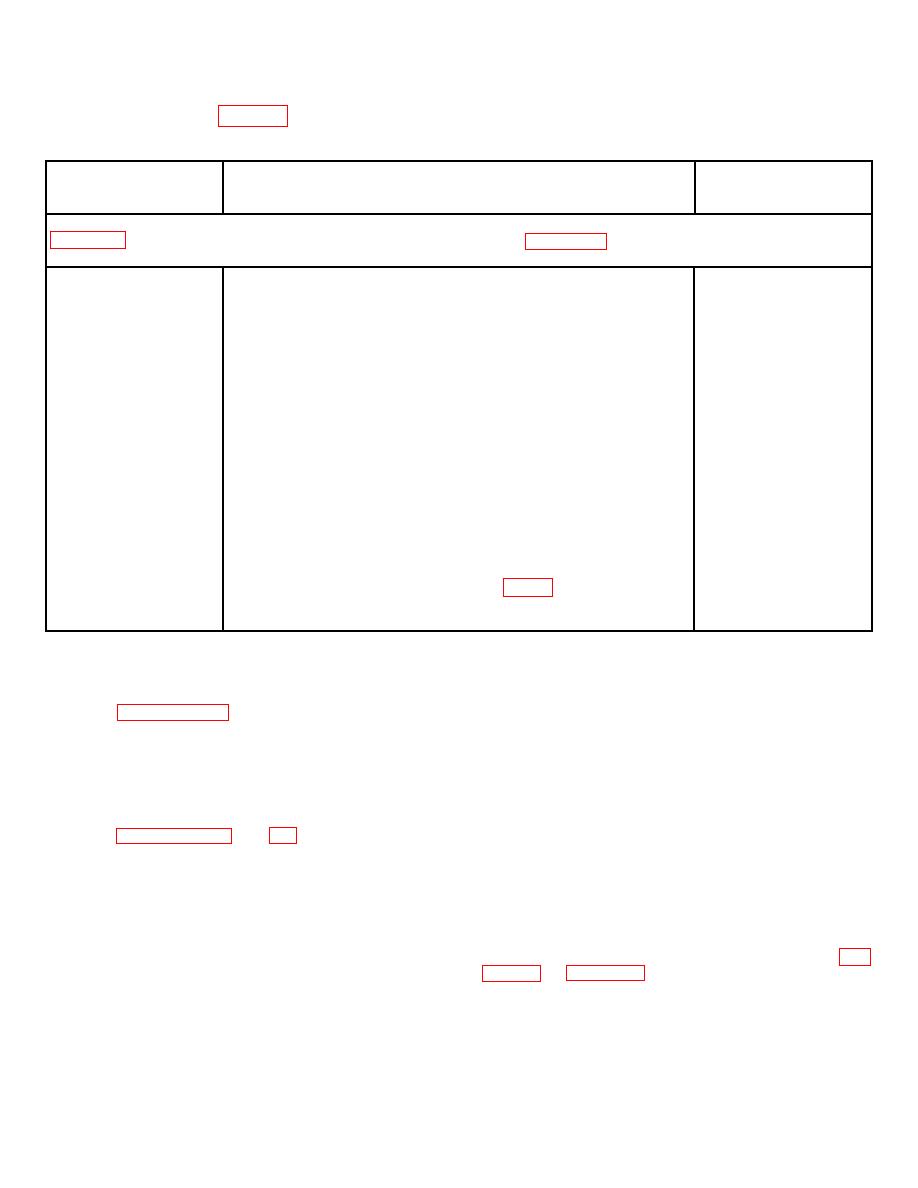

Table 4-1. Organizational Preventive Maintenance Checks and Services

Q-Quarterly

Total man-hours required 2.2

Work

Sequence

ITEM TO BE INSPECTED

Time

Number

PROCEDURE

(M / H)

NOTE

Figure 3-2(1) thru (3) illustrates items for models 2195-1 and 2195-2. Figures 3-3(1)i thru (3) illustrates items for models

2271 and 2272. Figure item number is same as sequence number.

1

PIVOT POINTS

0.2

Lubricate in accordance with LO 5-420-205-15.

2

HOSES AND FITTINGS

0.3

Inspect for cracks and leaks. Tighten loose fittings. Replace worn

or frayed hoses.

3

TUBING AND FITTINGS

0.3

Inspect tubing and fittings for cracks and leaks. Tighten loose or

leaking fittings.

4

FRAME ASSEMBLY

0.5

Clean and inspect for damage.

5

HYDRAULIC CYLINDERS

0.3

Inspect for damage or leaks. Replace a defective cylinder.

6

CURBING

0.2

Clean and inspect for damage. Replace damaged curbing.

7

LOCKING PINS AND GUIDES

0.2

Clean, inspect and lubricate. Replace damaged or defective pins

and guides.

8

ROTATION ASSEMBLY

0.2

Lubricate the superstructure spline 112, fig. 3-1(4)) with GAA

automotive and artillery type grease. (See current LO 5-5420-205-

151.

Section VI. REPLACEMENT OF DATA/ INSTRUCTION PLATES

Remove attaching drivescrews and data/instruction

4-11. General

plate from superstructure and install new plate. Make

Refer to paragraph 1-8 for description and general

sure the new plate is for the correct superstructure

location of data plates and instruction plates.

model.

4-12. Replacement

Section VII. MAINTENANCE OF SUPERSTRUCTURE HYDRAULIC COMPONENTS

Appendix C, TM 5-5420-210-12 for models 2271 and

4-13. General

2272).

Refer to paragraphs 2-1 and 2-2 for the purpose or

b. Typical Application.

The hoses, tubes and

function of superstructure hydraulic components in

fittings supply high pressure hydraulic power from the

relationship to the transporter of the assault bridge ferry

transporter reservoir to the rotation, pinning, unfold and

unit.

folding, and curbing cylinders.

Tubing is used

4-14. Fittings, Hose, and Tubing Replacement

throughout the center section of each superstructure

a. General. The hoses, tubing, pipes, and fittings

with flexible hose to each cylinder. Quick-disconnect

required are of commercial (off the shelf) items. These

couplings are used at the rotation assembly (fig.

items are fabricated at GS level using high pressure

tubing and fittings assembled with special tools and

cylinder application.

equipment (Basic Issue Items List, Appendix B, TM 5-

5420-204-12 for models 2195-1 and 2195-2, and

4-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |