|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 38-400/NAVSUP PUB 572/AFMAN 23-210 MCO 4450.14/DLAM 4145.12

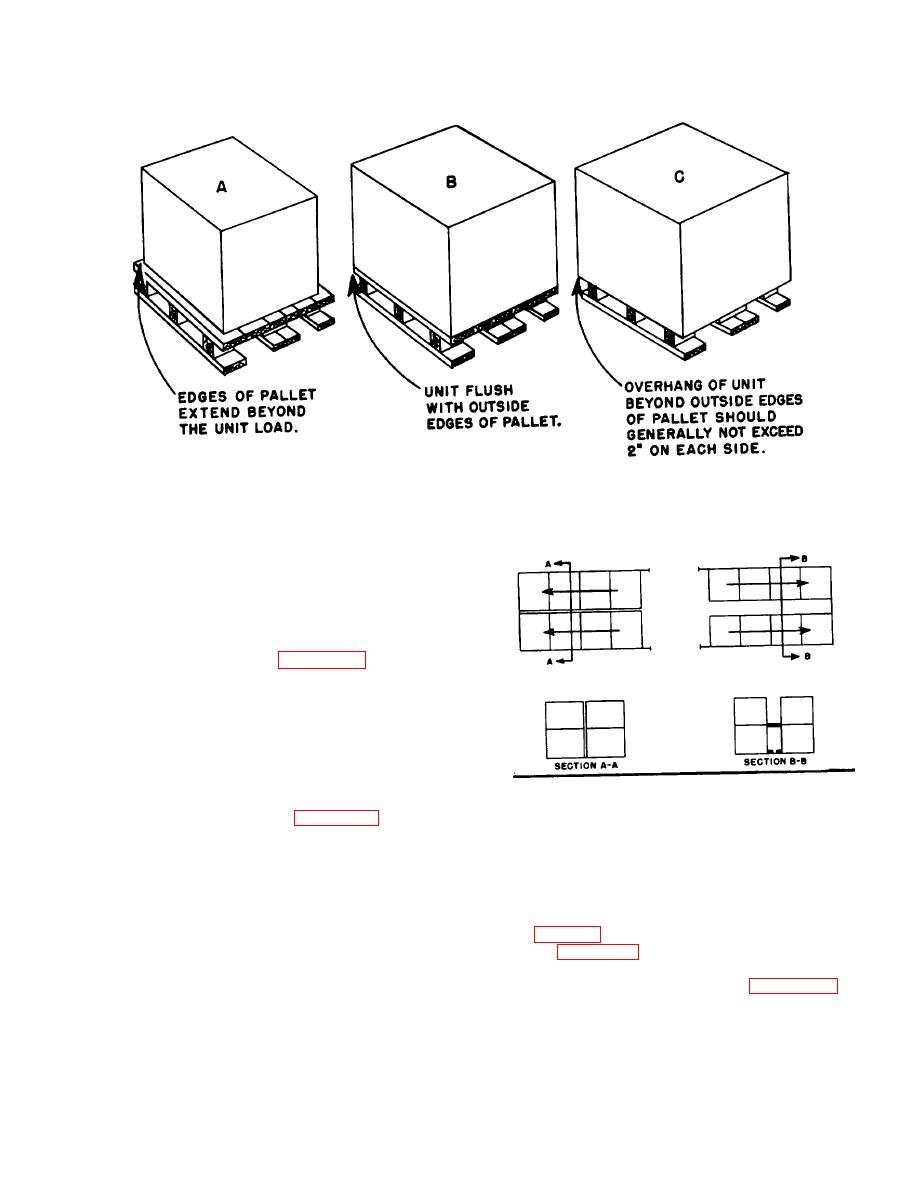

Figure 3-20. Prevention of chafing.

d. Loading factors.

(1) Tight loading. Pallets should be placed

tightly in both ends of the car. Generally, for practical

purposes, it is necessary to have some side clearance

space of approximately 1 to 2 inches between pallets in

order to maneuver the pallets into place by the forklift

truck. As shown in section AA, figure 3-23, the total

crosswise slack space between pallets and sidewalls in

the car is relatively small (approx 6 in) and, ordinarily,

would not require any additional crosswise bracing.

(2) Side shifting. In order to prevent side

shifting of load and with a possible derailment of car in

transit, circular 42F, Operating-Transportation Division

AAR, rule 5(C) requires "In boxcars, lading must be

Figure 3-21. Floor supports.

secured to prevent tipping or moving towards car sides

where the vacant space across car (figure 3-23, section

(3) Doorway space.

The loading at the

B-B) exceeds the following:

doorway is finished off with proper bracing to secure and

(a) A total of 18 inches between lading

hold the load in place during transit. The doorway

and car sides.

section of the load is a critical area in which to work, as

(b) Vacant cross car space of less than

space is needed to maneuver the forklift trucks or other

18 inches as may be specified in pamphlets covering

mechanical equipment which might be used (parts A

methods for loading, bracing, and blocking carload

and B, fig 3-24). For example, the space C, indicated

shipments of individual commodities."

on part A, figure 3-24, at the doorway is braced securely

by means of a wooden center gate D or steel strap

anchored gate E indicated on part B, figure 3-24. By

this method, the bracing can be removed at destination

and with this work space in the doorway section, the car

can be unloaded without difficulty.

3-55

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |