|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM

9-2350-238-20-2

9

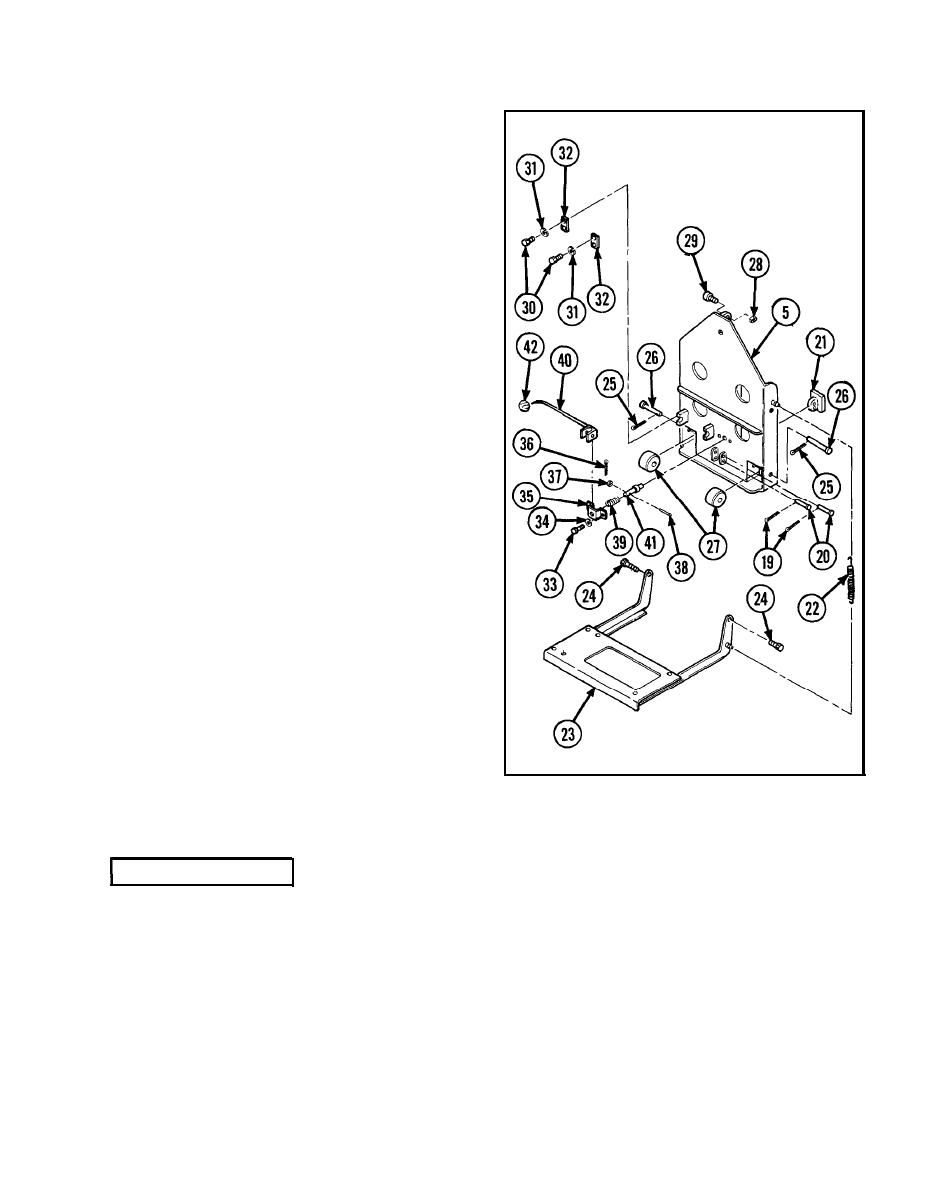

Remove two cotter pins (19), two head-

ed straight pins (20), vertical adjust seat

guide shoe (21).

10

Remove two helical extension springs

(22) from

rigger

and

gunner

seat

support

(23).

11

Remove two shoulder screws (24) and

rigger and gunner seat support (23) from

cab seat frame (5).

12

Remove two cotter pins (25), two head-

ed straight pins (26), and two seat back

rollers (27).

13

Remove

hexagon

plain

nut

(28)

and

nee-

dle bearing bolt (29) from cab seat frame

(5).

14

Remove four hexagon capscrews (30),

four Iockwashers (31), and two vertical

adjustment handle connecting links (32).

15

Remove two hexagon capscrews (33)

and two Iockwashers (34), releasing re-

taining strap (35) from cab seat frame

(5).

16

Remove cotter pin (36), flat washer (37),

and headed straight pin (38).

17

Remove helical spring (39), manual con-

trol lever (40), and headless shoulder pin

(41).

18

Remove knob (42) from manual control

lever

(40).

lNSPECTION/REPAIR

1 Check

for

broken,

damaged,

or

missing

parts.

2 If

cab seat frame

is

broken,

damaged,

or

missing,

repair

is

by

replacement

of

next

higher

assembly.

3 If

rigger

and

gunner

seat

support

is

broken,

damaged,

or

missing,

repair

is

by

replacement

of next higher assembly.

4 Repair

is

by

replacement

of

authorized

parts

(TM

9-2350-238-24P-2)

which

do

not

meet

in-

spection

criteria.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |