|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2350-238-20-1

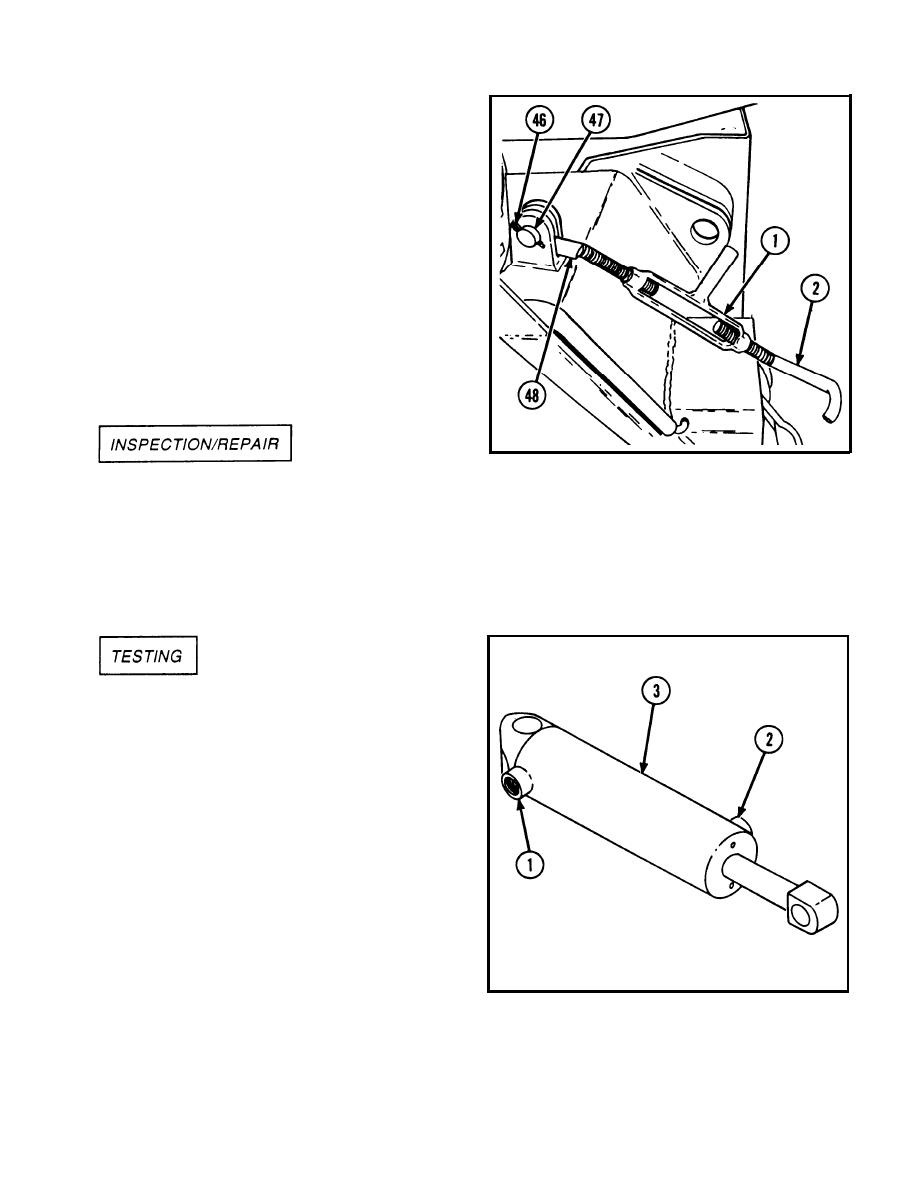

29 If damaged, remove cotter pin (46),

headed straight pin (47), eye bolt (48),

turnbuckle body (1), and hook bolt (2).

3

Repair is by replacement of authorized

1 Inspect for broken, damaged, or missing

parts (TM 9-2350-238-24P-1) which do not

parts.

meet inspection criteria.

2 Hydraulic cylinder assembly is a repairable

assembly. Notify direct support

maintenance.

1

Connect a 3000 psi (20,685 kPa) hydraulic

pressure source to port (1).

2

Slowly increase pressure to 3000 psi

(20,685 kPa).

Allow pressure to remain constant for 5

3

minutes.

4

Check leakage from port (2). It must not

exceed 1/4 teaspoon (1 cc) per minute.

Reduce hydraulic pressure to zero.

5

Disconnect pressure souce from port (1).

6

7

Drain hydraulic cylinder assembly (3).

Repeat steps 1 thru 7 for port (2).

8

2-973

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |