|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-20-2

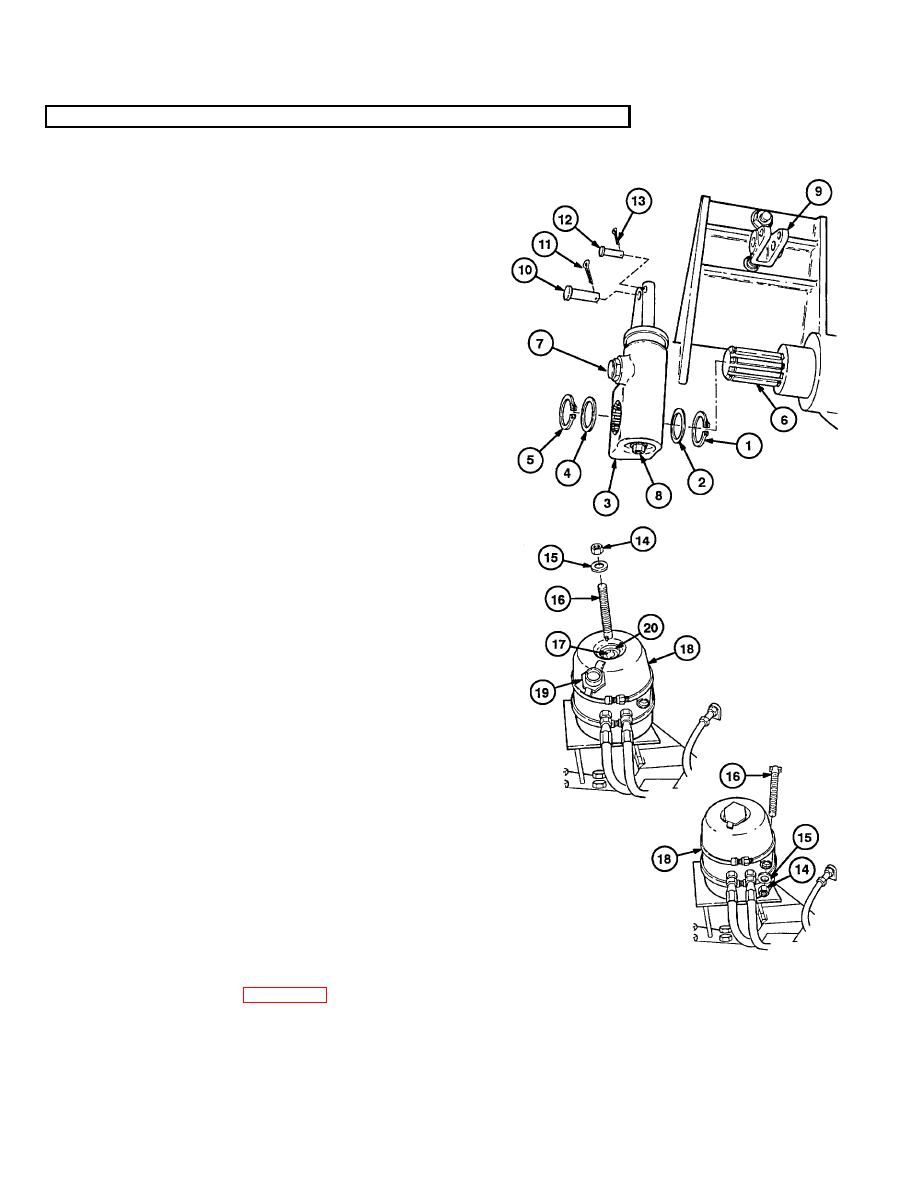

11-4.2. SLACK ADJUSTER (AUTOMATIC - AXLES NO. 2, 3 & 4) REPL (CONT)

c. Installation

NOTE

Install slack adjuster so that pawl

faces away from brake drum.

Axles no. 2 and no. 3 do not

have a snap ring between axle

housing and washer.

Washers should be installed as

marked during removal.

(1) Install snap ring (1), washer(s) (2), slack

adjuster (3), washer(s) (4), and snap ring

(5) on brake camshaft (6).

CAUTION

The pawl must be pulled out when

rotating the manual adjusting nut.

Failure to comply will result in

damage to slack adjuster.

(2) Pull pawl (7) out while turning adjusting

screw (8) clockwise until holes in clevis (9)

and slack adjuster (3) are aligned.

(3) Install pin (10) through clevis (9) and slack

adjuster (3).

(4) Install new cotter pi n (11) in pin (10).

(5) Install pin (12) through clevis (9) and slack

adjuster (3).

(6) Install new cotter pin (13) in pin (12).

(7) Loosen and remove nut (14) and washer

(15) from tool (16).

(8) Push

tool

(16)

down,

turn

counterclockwise 90. Pull out of slot (17)

inside brake chamber (18).

(9) Install dust cap (19) in access hole (20).

(10) Install tool (16), washer (15), and nut (14)

in mounting position on brake chamber

(18). Tighten nut.

d. Follow-On Maintenance

(1) Grease slack adjuster (LO 9-2320-360-

12).

(2) Adjust brakes (para 11-2.1).

Change 3 11-11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |