|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-20-2

NOTE

Number of balance weights installed

on splined shaft vary.

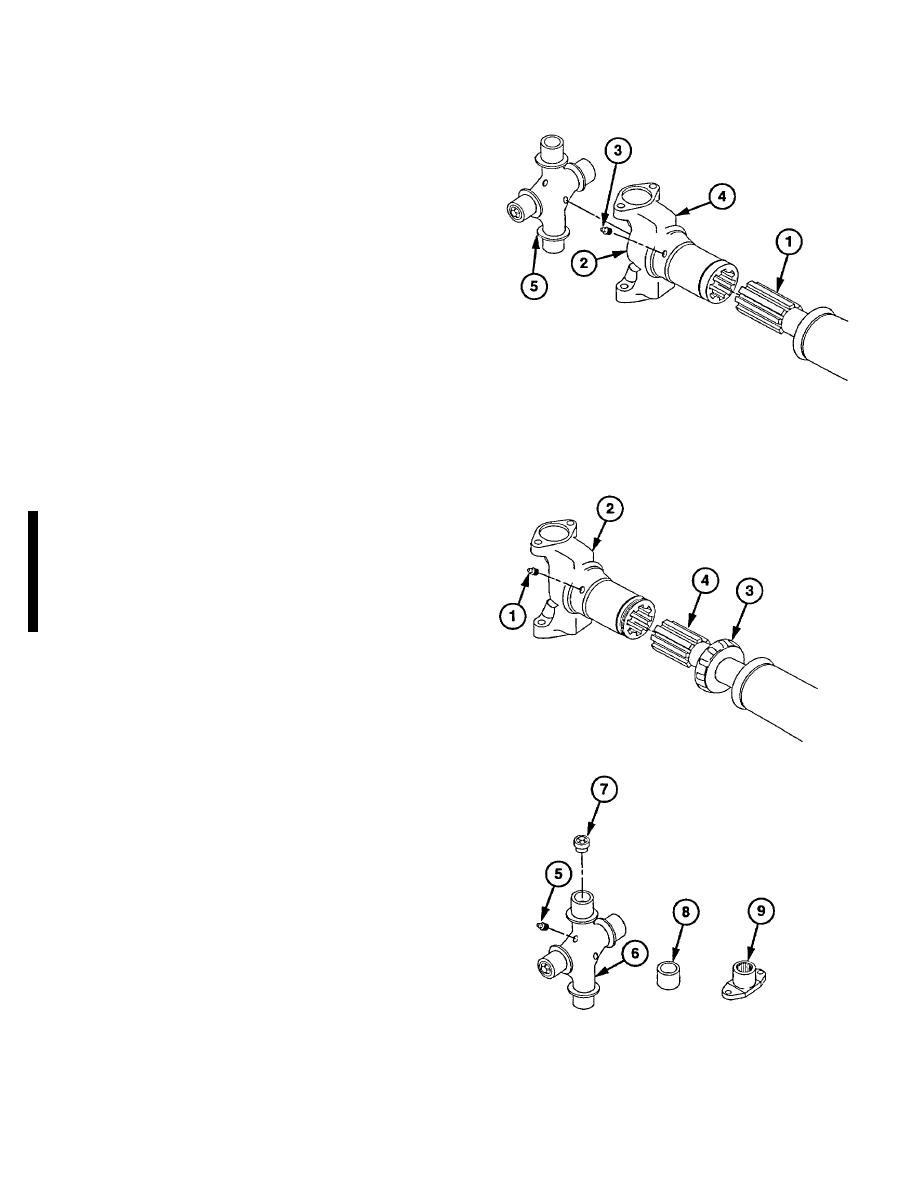

(3) Inspect splined shaft (1) for damage, bent

tubing, or missing balance weights.

(4) Remove burrs from surfaces where prying

occurred.

(5) Remove foreign material (paint, rust, etc.)

build up on propeller shafts and

components.

(6) Inspect for missing or damaged end plug

(2) and grease fitting (3) on slip yoke (4).

(7) Inspect slip yoke (4) for broken, damaged,

or missing teeth.

(8) Inspect universal joint cross (5) for wear.

d. Assembly

CAUTION

Propshaft parts must be positioned

in locations marked during removal.

Failure to comply may result in

driveline vibration and damage to

equipment.

(1) Install grease fitting (1) on slip yoke (2).

(2) Install dust cap (3) on splined shaft (4).

(3) Install slip yoke (2) on splined shaft (4).

(4) Install dust cap (3) on slip yoke (2).

NOTE

Some

universal joints

have

two

fittings.

(5) Install fittings (5) in universal joint (6).

CAUTION

All four check valves must be

installed

correctly,

otherwise

lubricant will not flow through check

valves and may cause equipment

damage.

(6) Install check valves (7) in universal joint (6).

(7) Coat inside of bearing caps (8 and 9) with

grease.

Change 1 10-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |