|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-285-24-2

4-5. DIFFERENTIAL (CONT)

STEP

LOCATION

ITEM

ACTION

REMARKS

REASSEMBLY (cont)

26

d. Bearing spacer

Install

Onto drive pinion (28) shaft,

(cont)

(36)

bevel side toward shaft

shoulder

e. Outer bearing

Install

Press onto drive pinion

(31)

NOTE

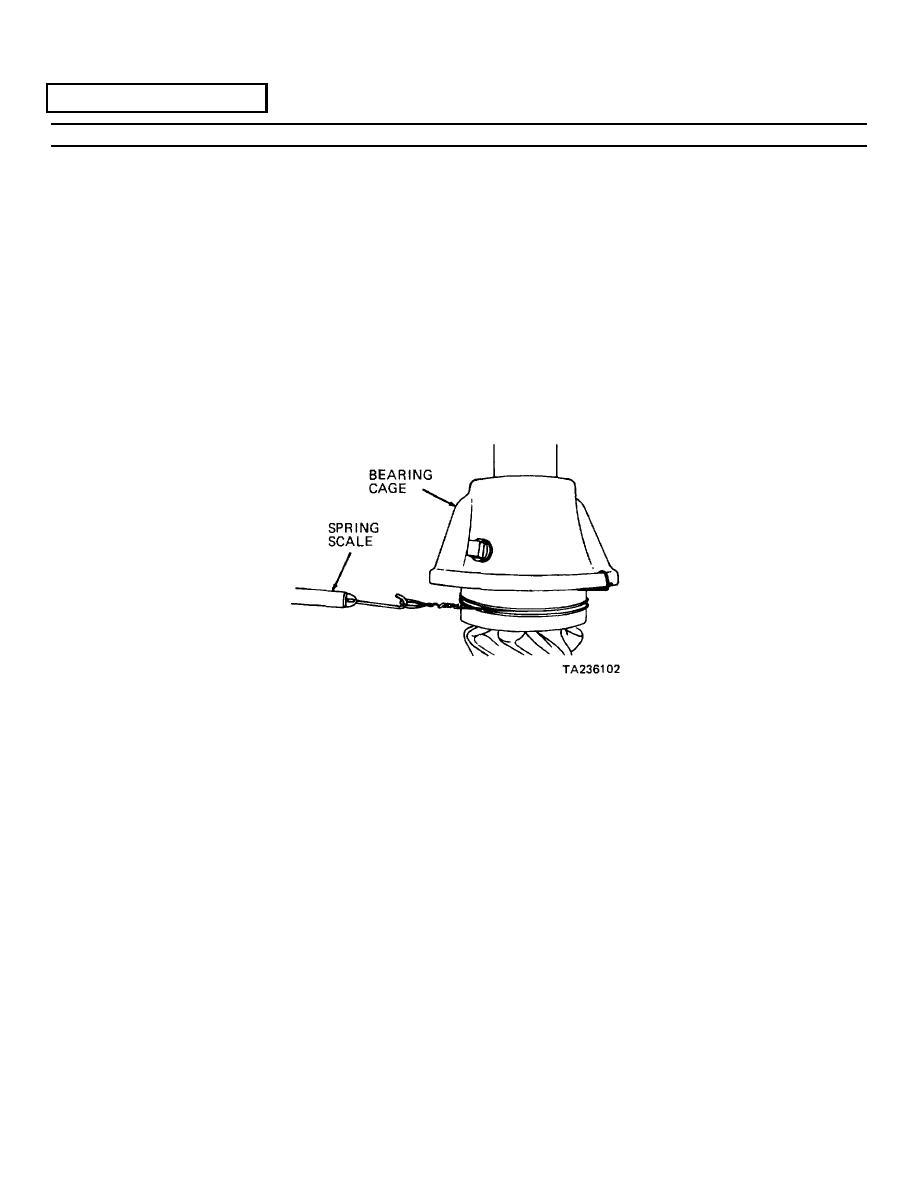

While still in press, rotate bearing cage (25) several times to assure normal bearing contact.

f. Pound scale

Check drive

Pull horizontally on soft wire

pinion (28)

wrapped around bearing cage

bearing

(25) as shown, while bearing

preload

cage is still in press,

under 14 tons of pressure

NOTE

You can also check preload with yoke (21) installed and nut (23) tightened to 800-1100 pounds foot.

Example: Assume bearing cage (25) diameter is 6 inches; radius would be 3 inches. Five pounds pull on

scale would equal 15 pounds inch bearing preload torque. Use rotating, not starting torque. Use thinner

bearing spacer (36) to increase or thicker spacer to decrease bearing preload if turning torque is not within

5-15 pounds inch. Remove bearing cage (25) from press.

g. Oil seal (30)

Install

Coat outer edge with non-hard-

ening sealer and press firm-

ly against bearing cage (25)

4-159

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |