|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-285-24-2

4-4. TRANSMISSION (CONT)

b. Main Shaft and Gear Unit Assembly (cont).

STEP

LOCATION

ITEM

ACTION

REMARKS

REASSEMBLY (cont)

1/2 inch guide pins. Press into flange and

carrier assembly (30) until pin installer

14

touches flange and carrier assembly

(cont)

Swage. Remove flange and carrier assembly

(30) from removing, installing and swaging

f. Six pins (31)

fixture. Install bottom swaging tool holder

into fixture. Install one swaging tool

J-25587-27 into bottom swaging tool holder

and one into fixture. Lubricate both ends

of pins (31) with oil-soluble grease. Posi-

tion flange and carrier assembly (30) rear

end up on fixture. Use support block

J-25587-4 to level flange and carrier

assembly while lower swaging tool is sup-

porting lower end of pin (31). One pin at a

time, apply pressure gradually (about two

tons) to swage ends of pins against flange

and carrier assembly (30), as shown. Pinion

set (34) must rotate freely and have 0.008-

0.031 inch end play. Remove flange and

carrier assembly from fixture. Remove bot-

tom swage tool holder from fixture

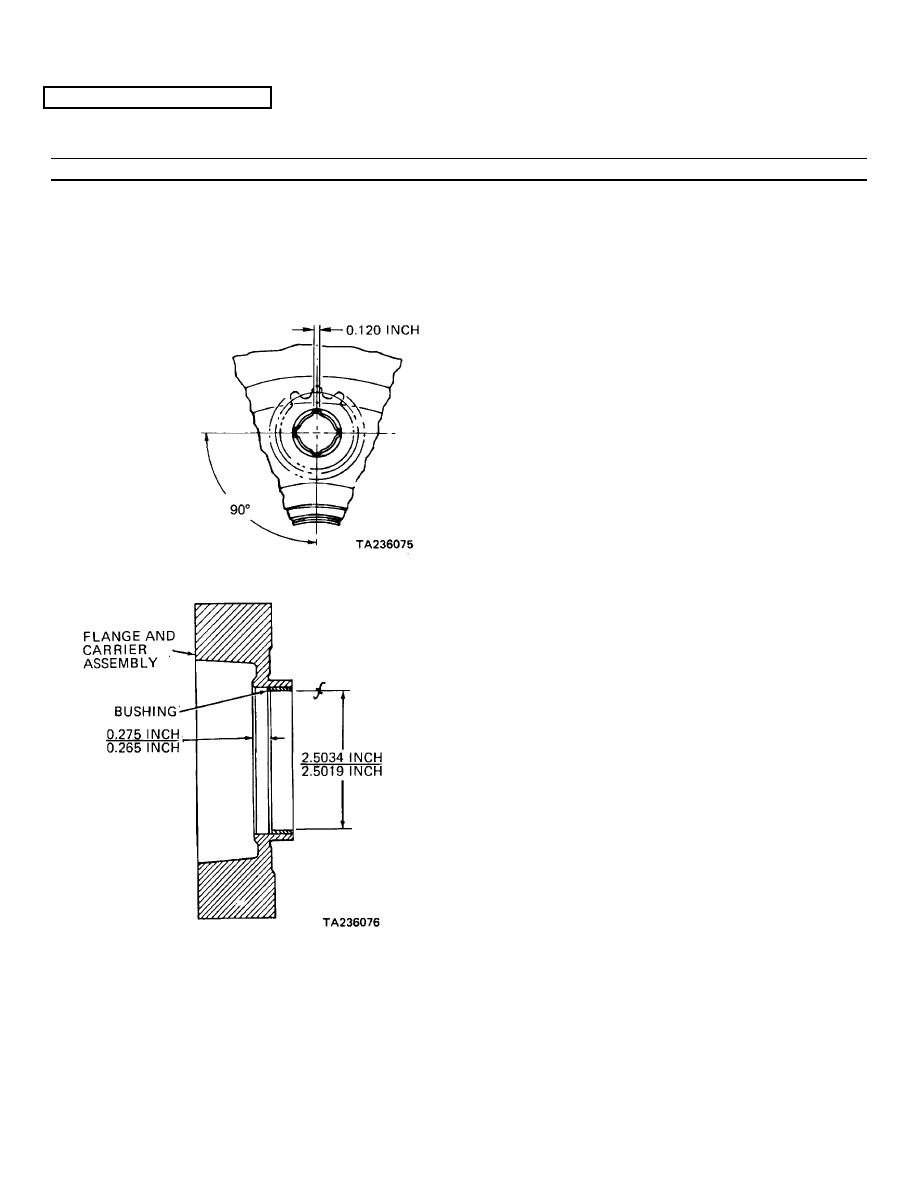

Use front planetary bushing

installer to press bushing

(29) into flange and carrier

assembly to dimension shown

4-32

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |