|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-1270-212-14&P

e. Apply a drop of sealing compound conforming to

MIL-S-22743, grade T (primer) and grade H, to the threads

of the shaft and nut. Install swivel nut (28) and tighten to

NOTE

a torque value of 5 inch-pounds with a torque wrench.

Disassemble only items necessary to complete

f. Tighten three setscrews (27) to hold magnet in

repair procedures.

position.

g. If a new magnet is installed, mark a spot in the epoxy

of magnet (29) closet to the white mark on receptacle (33).

b. Assemble in reverse order, referring to c through i.

h. Drill a 1/8-inch-diameter hole, 0.010 inch deep, in

the marked spot in the epoxy, being careful not to hit the

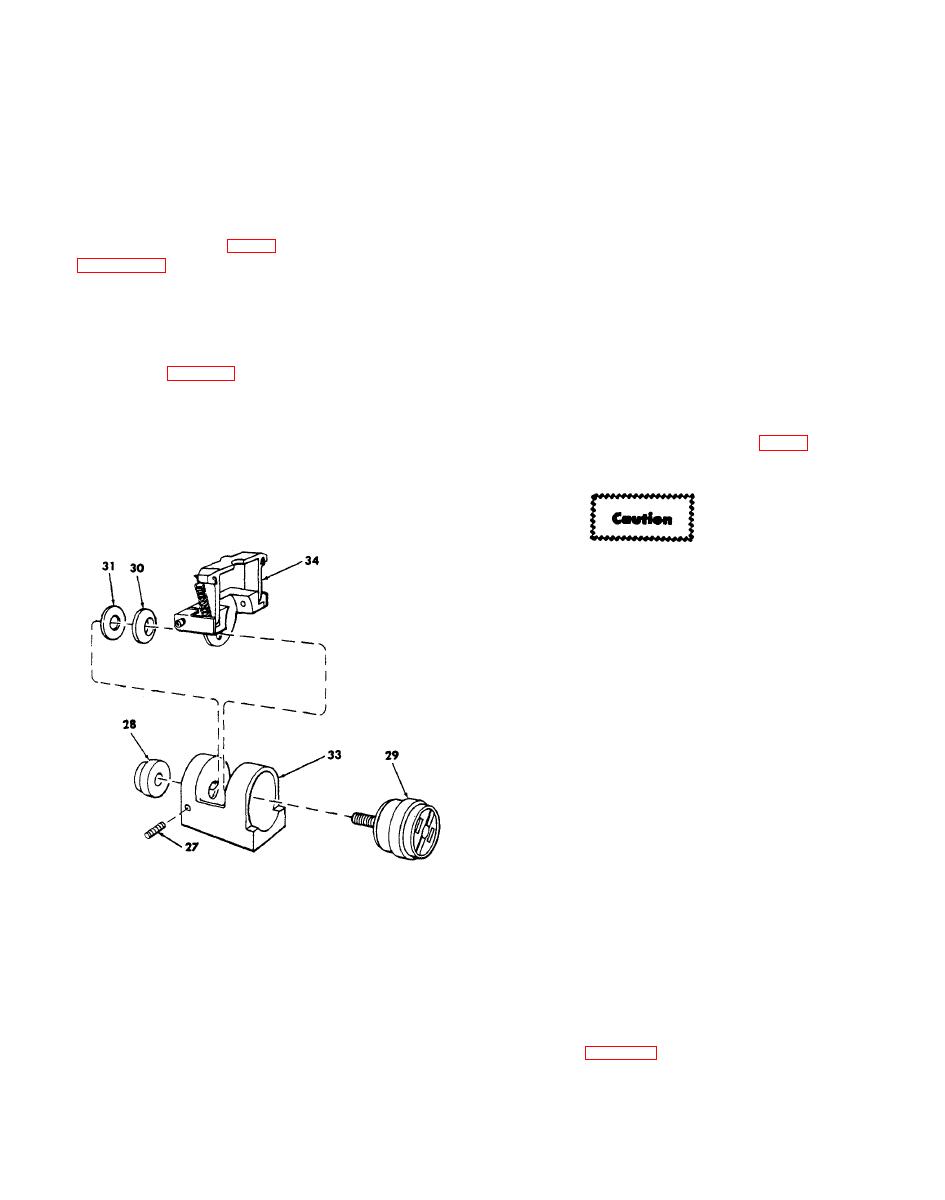

c. Assemble latch assembly (34) as shown.

magnet.

d. Refer to figure 5-2. Install setscrews (27) loosely so

i. Fill the hole with white epoxy conforming to

that they will not touch the shaft on magnet (29).

MS18038-91.

Assemble" convex washer (30), flat washer (31), latch

assembly (34), and magnet (29) into helmet receptacle

(33). Rotate the magnet to align the white dots. If a new

magnet is being installed, rotate the magnet so that

continuit y exists between A1Pl-5 and -6 with a linkage arm

assembly steel fastener (or the helmet boresight tool)

attached to the magnet (29) and so that an open circuit

exists when the steel fastener is disconnected.

Do not disturb or remove the flathead screw at

the falter-assembly (5) end of straight shaft (8).

The screw is a part of the filter assembly and is

bonded in place.

a. Remove items (1) through (14) and assemble

reverse order.

b. Apply a drop of sealing compound conforming to

MIL-S-22473, grade T (primer) and grade H, to bond the

cap (12) to the sight housing (36).

New SPH-4 Helmet (fig. 5-l).

NOTE

Installation items called out in this paragraph

are furnished with a new helmet sight assembly.

NOTE: FOR PROCEDURAL CLARITY AND FOR PURPOSES OF

THIS FIGURE ONLY, SPECIFIC ITEMS FROM FIGURE

B-2 ARE IDENTIFIED.

a. Remove the visor housing and visor from the helmet

AR 401075B

27 Setscrew (3)

by removing the four mounting screws and mounting nuts.

28 Swivel nut

29 Magnet

NOTE

30 Convex washer

31 - Flat washer

The visor housing will not be reinstalled and it

33 Helmet receptacle

and its mounting screws and mounting nuts do

34 Latch assembly

not appear on figure 5-1. Dispose of the visor

housing according to local instructions.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |