|

|||

|

|

|||

|

Page Title:

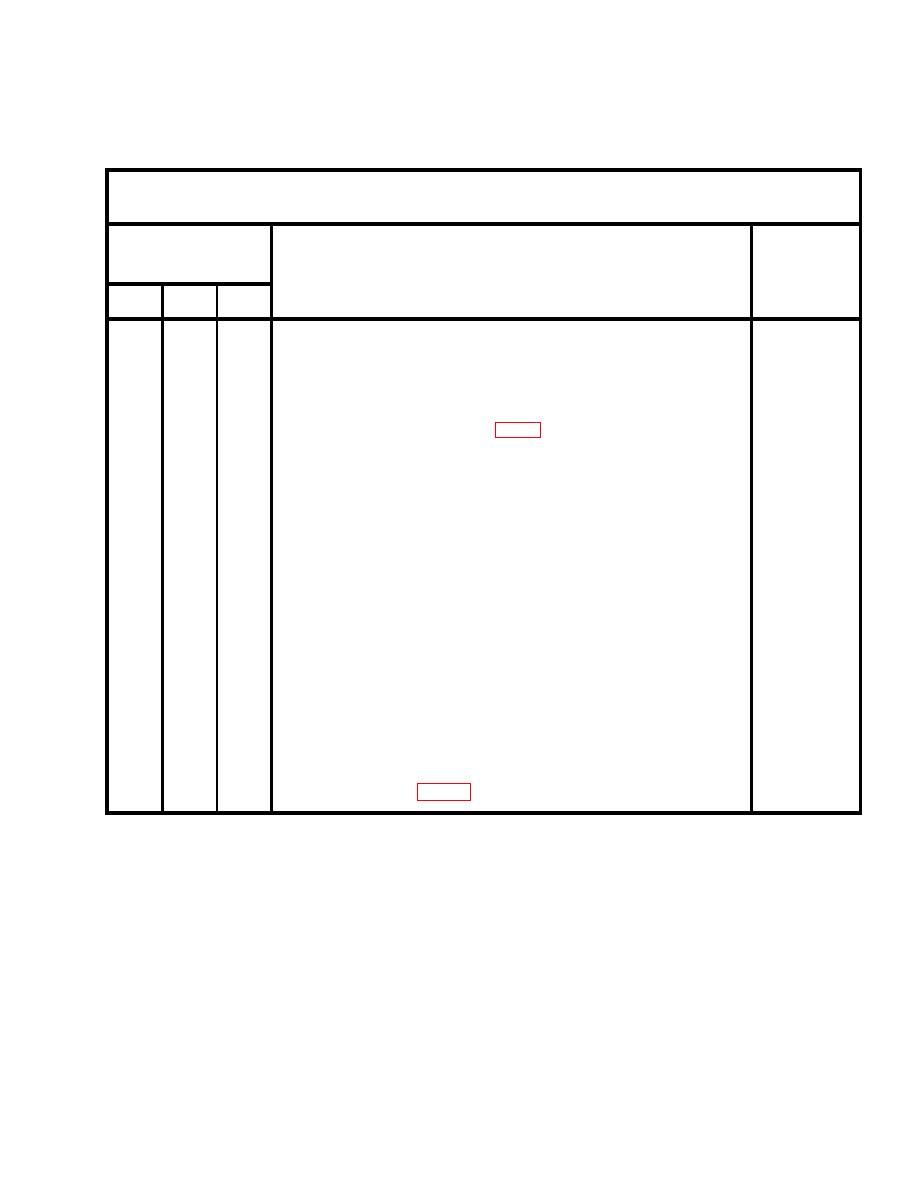

Table 3-2. Preventive Maintenance Checks and Services - Mechanical |

|

||

| ||||||||||

|

|

TM 9-1270-212-14&P

D - During operation

A - After operation

B - Before operation

time required: 0.1

time required: 0.1

time required: 0.5

Interval and

Item to be inspected

sequence number

Work time

procedure

(M/H)

A

B

D

Helmet sight assemblies

1

Inspect for damage (bent or broken parts).

0.2

Inspect for evidence of misalignment.

Inspect for dirty optics.

Perform sight unit retract test (fig. 3-1).

2

Linkage assemblies

0.2

Inspect for damage (bent or broken parts).

Inspect rails for nicks, foreign material, or corrosion. Wipe rails with

lint- and dust-free cloth.

Electronic interface assembly and cabling

3

0.1

Inspect for physical damage to cabling and insure that connectors are

secure.

4

Linkage assemblies

0.1

Check for unusual feel or binding when linkage is attached to helmet.

5

Linkage assemblies

0.1

Remove linkage arm assemblies from helmet receptacle and place in

stow position (fig. 2-10).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |