|

|||

|

|

|||

|

Page Title:

AFT ROTOR AND PYLON AREA (RIGHT SIDE) (Cont) |

|

||

| ||||||||||

|

|

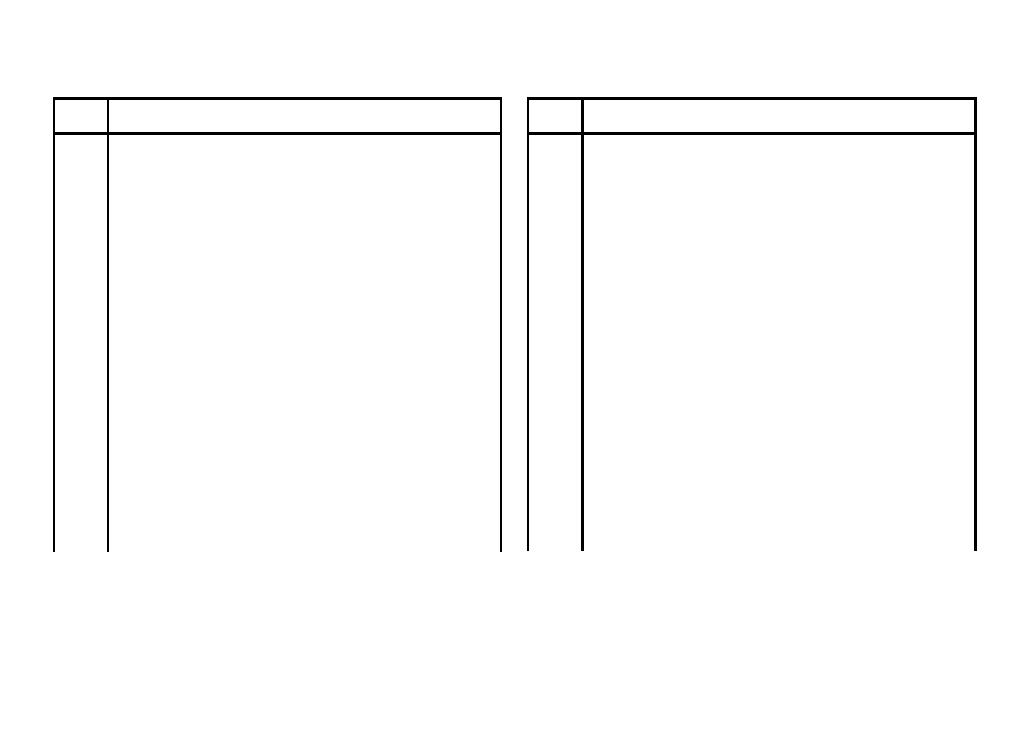

Seq.

Seq.

No.

Item and Procedure

No.

Item and Procedure

10.11

10.18

Swashplate for signs of damage, overheating, and

Power transfer unit for leakage and security.

accumulation of grease. Using a flashlight or other

Operate bleed valve on flight control hydraulic reservoir

10.19

suitable light source, visually inspect with a mirror or

until fluid is free from air.

flexible borescope the area between the underside of

Utility and flight control hydraulic reservoirs/coolers for

10.20

the rotating ring and stationary ring for any slinging or

proper fluid level, leaks, and security. Utility accumulator

clumping of grease/debris (i.e. seal, bearing cage, seal

for proper pressure.

spring, wire, or other material). A thin bead of grease

10.21

Combining and engine transmission cooling fan exhaust

around the sealing area is considered normal.

duct for security, damage, and obstruction.

10.12

Aft vertical shaft and bearing for leaks and signs of

10.22

Combining and engine transmission oil coolers for leaks,

overheating. Housing mounts and adjacent structure for

clogged or damaged core, and foreign objects. Cooler

cracks, buckling, damage, and loose or missing hardware.

housing for cracks and corrosion. Transfer tubes for

10.13

Upper boost servocylinders for leaks and security. Jam

damage. Oil pressure switches/transducer for condition.

sensors for extended warning indicators. Exposed piston

10.23

Combining transmission and engine transmission

rods for cleanliness.

reservoir sight gages (3 places) for proper oil level.

10.14

Flight control bellcranks, connecting links, and idlers

in pylon area for cracks and security. Connecting link

NOTE

swaged inserts for evidence of looseness.

10.15

Longitudinal cyclic trim yoke for security and condition.

To prevent overfilling transmission, check oil level

Yoke attaching hardware for security and condition.

within 30 minutes of shutdown. If transmission

10.16

Utility and No. 2 light boost cooling fan for condition and

has been shut down for more than 30 minutes,

adjacent structure for cracks.

operate rotors for a minimum of 5 minutes to verify

oil level before servicing.

10.17

Flight boost power control module for leaks and security.

Accumulator for proper precharge. Filters contamination

10.24

Combining transmission and engine transmission main

lube filters for extended warning indicators (3 places).

and pump fault indicator for extended warning indicators.

"FOD REMINDER"

CHECK WORK AREA FOR TOOLS AND PARTS AFTER COMPLETION OF MAINTENANCE AND INSPECTION.

TM 55-1520-240-PMD

Change 1 19

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |