|

|||

|

|

|||

|

Page Title:

CHAPTER 6 DIRECT SUPPORT (INTERMEDIATE) MAINTENANCE INSTRUCTIONS |

|

||

| ||||||||||

|

|

TM 5-6350-262-14/4

CHAPTER 6

DIRECT SUPPORT (INTERMEDIATE) MAINTENANCE INSTRUCTIONS

Section I. GENERAL

6-1. Maintenance Concept

a. Personnel Requirement.

A radio mechanic (Government Occupational Job Code 823.281, or equivalent

military job code) should be capable of performing direct support (intermediate) level maintenance of the MWS without

specialized training.

b. Preventive Maintenance.

Periodic replacement of batteries in the SPU is the only preventive maintenance

requirement at the direct support (intermediate) maintenance level.

c. Corrective Maintenance.

Corrective maintenance of the MWS at the direct support (intermediate) level

will consist of limited troubleshooting, repair (by replacement), and verification testing..

(1) Troubleshooting will be accomplished in accordance with Section II.

(2) Repair will be accomplished in accordance with Section III.

(3) Testing will be accomplished in accordance with Section IV.

6-2. Maintenance Tools and Equipment

a. No special tools or test equipment are required to perform allocated direct support (intermediate) maintenance

functions.

b. Standard tools and test equipment required to perform allocated direct support (intermediate, maintenance

functions are listed in table 6-1.

6-3. Maintenance Materials

All materials and supplies needed to perform allocated direct support (intermediate) maintenance functions are listed in

table 62

6-4. Repair Parts

All repair parts authorized for direct support (intermediate) maintenance are listed in Appendix C

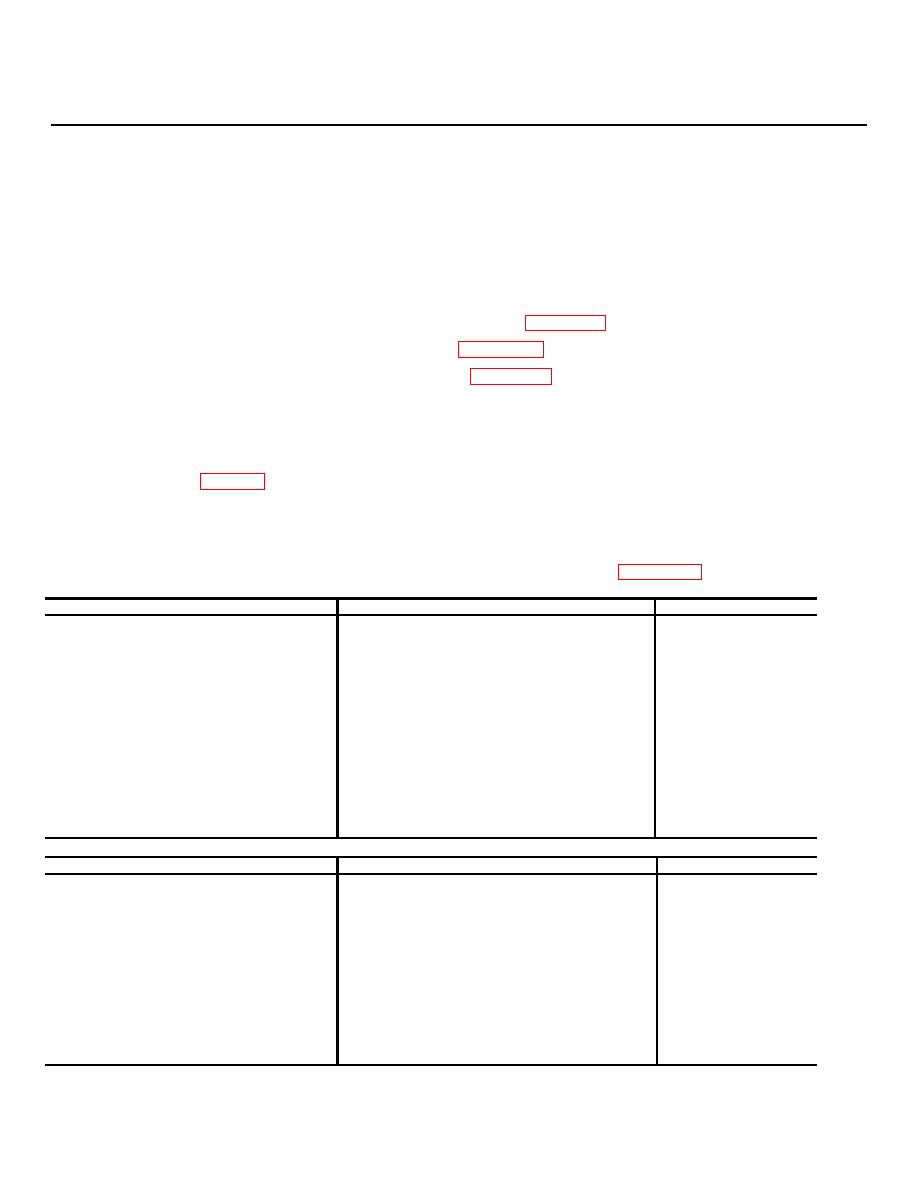

Table 6-1. Maintenance Tools and Equipment

Items

Purpose

Applicable

paragraph

Crimping tool

Repair or replace interconnecting

6-6

wires (electrical hookup)

thru

Pliers, diagonal cutting

6-22

Pliers, long nose

Wirestripping tool

Heat sink, miniature-(2)

Remove or replace batteries

Soldering iron, 40W

Repair or replace wiring

Screwdriver, blade tip, 1/4 inch

Tighten or loosen screw fasteners

Adjust SENSITIVITY

Electrical check/tests

(Voltohmmeter)

Troubleshooting

DC Power Supply

Bench test of MWS

6-19

(O to 20 VDC)

Table 6-2. Maintenance Materials

Items

Purpose

Applicable

paragraph

Tape, double-coated

Attach replacement EOL Module

2-8

can to rack

Tape, self-adhesive

Secure loop sensor to rack

2-8

Solder, Sn 60

Repair or replace wiring

6-13

Replace batteries

thru 6-17

Wire, electrical, AWG22

Replace hookup wires

(MI L-W-16878)

Insulation, tubular

Replace filter chokes in chassis

AWG 22 (MIL-I-22129)

Adhesive (MILA46106)

Solvent

6-1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |