|

|||

|

|

|||

|

Page Title:

Table 1-1. MWS Components and Nomenclature |

|

||

| ||||||||||

|

|

TM 5-6350-262-14/4

contact between the cover, gasket edge, and chassis rim. The metal-to-metal contact provides an effective EMI shield.

Removal of the cover from an operating unit activates a tamper alarm. The MWS identification plate and an assembly

information plate are affixed to the inside of the enclosure. Both plates are made of aluminum foil and have a self-

adhesive backing.

c. Printed Wiring Board (PWB) Assembly. All MWS signal processing electronics are mounted on one printed

wiring board. The anti-tamper switch, the SENSITIVITY control, and the two-battery internal power supply are also

mounted on this board. The adjusting screw in the tamper switch plunger projects 3/16 inch beyond the front edge of the

chassis. he switch contacts are open at this time.) The switch contacts may be closed by pulling the extension outward.

The contacts also are closed by installing the SPU cover on the chassis. (A spring on the plunger opens the switch

contacts when cover pressure is removed.)The SENSITIVITY control is a screw adjustable potentometer. The adjusting

screw is indexed. The settings are printed on a transparent plastic disk. The two batteries are mounted in tandem in

clips on the back of the board. The batteries are equipped with ribbon lead wires. These lead wires are soldered to

slotted terminals on the board. Three 0.62-inch diameter holes through the board provide access to the chassis

mounting fasteners. These holes also serve as finger grips to facilitate handling during board removal, reinstallation, or

replacement. The PWB Assembly is protected against moisture by a conformal coating. This coating is necessary to

prevent degradation of electronic function. It also reduces the feasibility of isolating and replacing defective discrete

components on the board.

d. End-of-Loop (EOL) Module.The EOL Module consists of a toroidal inductor, a resistor, and two screw terminals.

These items are mounted on a terminal board and are conformally coated. The board is mounted on two insulating pads.

The pads are secured to the bottom of a rectangular can. One end of the can has a slot to allow passage of the loop

sensor wires. The EOL Module assembly is completed by a shallow rectangular cover.

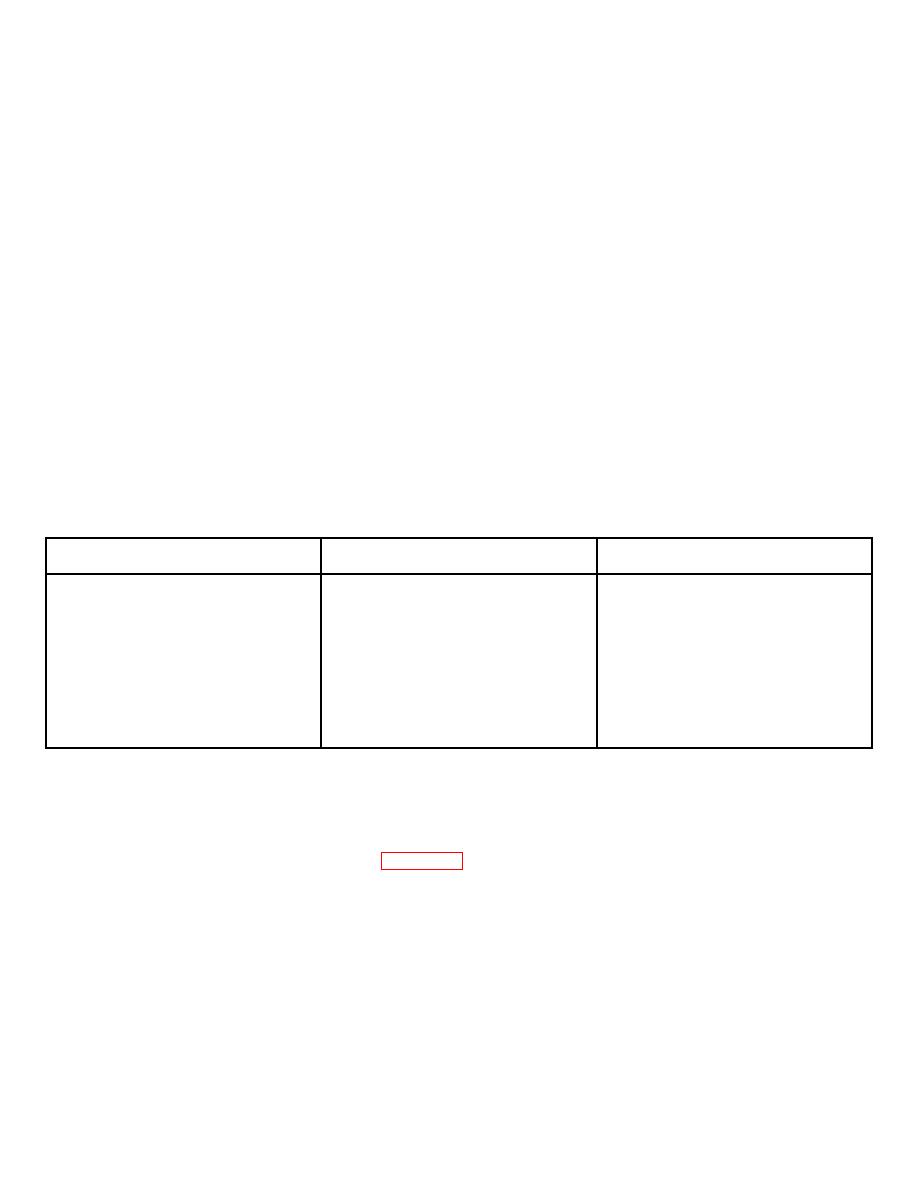

Table 1-1. MWS Components and Nomenclature

Parts lists

Narrative text

Abbreviated

Sensor, Magnetic Weapon

Magnetic Weapon Sensor

MWS

--Signal Processor Unit

SPU

Enclosure Signal Processor

--Enclosure

[SPU] enclosure

- - - Cover

[SPUE] cover

- - - Chassis

[SPU] chassis

Printed Wiring Board Assy

-- Printed Wiring Board Assembly

PWB Assembly

-- Loop Sensor

Loop Sensor

Toroid Assembly

- End-of-Loop Module

EOL Module

- - Cover

[EOL] cover

- - Can

[EOL] can

( ) Acronym used so modifier for emphasis or to distinguish between like items (e.g., cover)

A 7/32-inch diameter hole through the center of the cover, terminal board, and can, is provided for mounting the

assembly to the weapons rack.

e. Loop Sensor. The loop sensor is constructed from No. 16 AWG (insulated) wire supplied as part of the MWS. A

basic loop sensor configuration is shown in figure 1-2. It consists of two equal lengths of wire. All four ends are

terminated (at time of installation) with crimped, solderless spade terminals. One pair of ends is connected to the screw

terminals inside the EOL Module. The other pair of ends passes through the rubber grommet in the SPU enclosure

cover. These ends are connected to the screw terminals of the Input and Filter Assembly in the bottom of the SPU

chassis. The loop sensor is installed on or through a weapons rack Each loop sensor must consist of an even number of

subloops (2, 4, 6, etch Each pair of subloops must be approximately equal to each other in area (length times width of

one equals length times width of other, Subloops of different pairs may be longer or wider. Wherever the loop sensor

wires must cross an open space (as from the EOL Module to first subloop, between racks, or from last subloop to SPU

input) the wires must be twisted together. Approximately one turn per inch is sufficient to reduce noise to an acceptable

level Between subloops, the wires are transposed from one side to the other. Movement of the loop sensor wire can

generate false alarms Therefore, the subloop wires must be taut; or must be secured to a

1-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |