|

|||

|

|

|||

|

Page Title:

Section II. SERVICE UPON RECEIPT OF MATERIAL |

|

||

| ||||||||||

|

|

Section II. SERVICE UPON RECEIPT OF MATERIAL

2-7. Unpacking

2-8. Checking Unpacked Equipment

a. Packing Data. When packed for shipment, the

processor and the transceiver are each placed in a

a. Inspect the equipment for damage incurred(

separate corrugated carton with a minimum of 2 inches

during shipment. If the equipment has been damaged,

of foam padding on all sides. The carton measurements

report the damage on DD Form 6 (Report of Packaging

in inches, volume in cubic feet and weight in pounds are

and Handling Deficiencies).

as follows:

b.

See that the equipment is complete as

stenciled on the carton. Report all discrepancies in

Dimensions

accordance with TM 38-750.

Volume

Weight

H

W

D

Cubic Feet

Pounds

c.

If the equipment has been used or

Processor

14

13

5

0.652

7

reconditioned, see whether it has been changed by a

Transceiver

21

7

7

0.61

5

modification work order (MWO). If the equipment has

b. Removing Contents.

been modified, the MWO number will appear adjacent

to the nomenclature plate. If modified, see that any

operational instruction changes resulting from the

(1) Processor.

modification have been entered in the equipment

(a) Remove the staples securing the

manual.

corrugated gated carton flaps.

(b) Remove the foam padding and lift

NOTE

out the equipment.

(2) Transceiver.

Current MWO applicable to the

(a) Remove the staples securing the

equipment are listed in USASA PAM

corrugated carton flaps.

310-6 or DA APM 310-7.

(b) Lift the equipment out of the

carton with the foam padding attached. Remove the

foam padding from the equipment.

Section III. INSTALLATION INSTRUCTIONS

2-9. General.

separate configurations. The initial test setup is moved

from location to location and the prescribed tests are

Prior to permanently securing the transceivers in place

performed at each location. The second test setup

and permanently interconnecting all transceivers to the

requires a temporary signal wire run to each location

processor, a noise level test and a walk test of each

and checking' out the combined configuration of all

selected transceiver location must be performed to

locations.

insure adequate surveillance coverage.

b. Individual Location Test. Each transceiver

2-10. Tools, Test Equipment, and

location is to be noise tested and walk tested to evaluate

Material Required for Installation

the location. The noise test and walk test requires

temporary mounting of the transceiver in its intended

The tools, test equipment, and material listed in table 2-

location, interconnection between the processor and the

1 are required to perform testing and installation.

transceiver, an audible sounder to signal actuation of

the alarm circuit, a multimeter for evaluating the extent

of noise level, and the application of power. To facilitate

2-11. Test Setup

the walk test of each transceiver location, fabricate test

cables an(d temporarily interconnect the equipment in

a. General. The test setup recommended for

the test setup as shown in figure 24.

evaluating the selected transceiver locations entails two

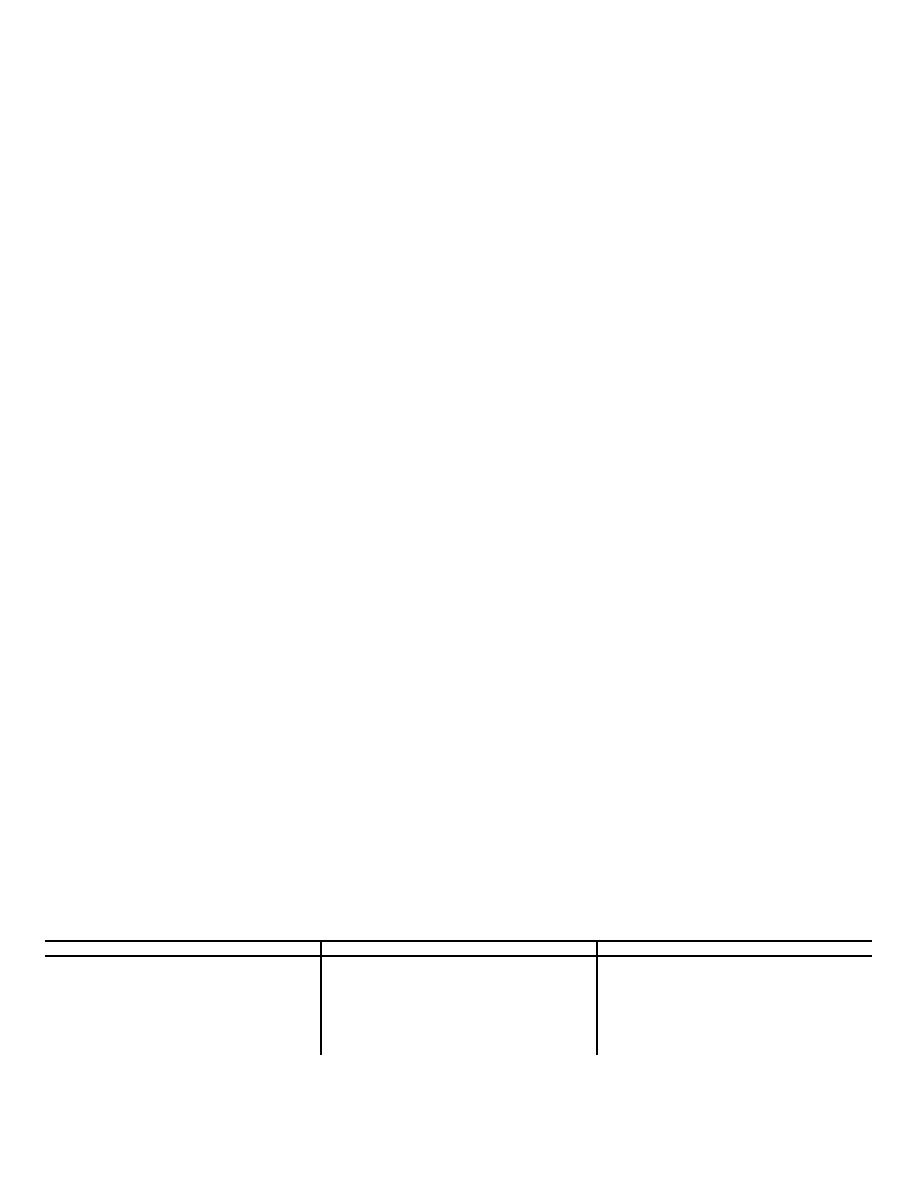

Table 2-1. Tools, Test Equipment and Material Required for Installation.

Item

Purpose

Applicable Publications

Power Supply PP-2309/b

Provides 20 2 Vdc for test setup

TM 11-6130-245-14-1

Multimeter AN/USM-210

Measure dc and ac voltage

TM 11-6625-1508-35

Fabricated Cables, five

Interconnect test setup

(see fig. 24)

Buzzer Mallory SC628

Audible alarm

Tool Kit TK-100( )G

Electric drill, inch and drills

Masonry drill, carbide tipped, inch dia.

Drill through masonry

2-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |